Demands for PCBs in Industrial Control

-

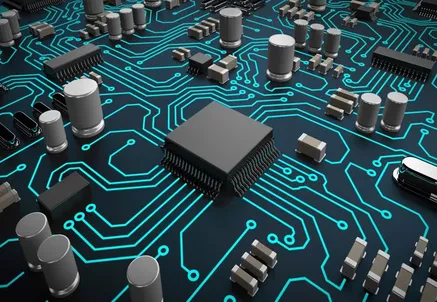

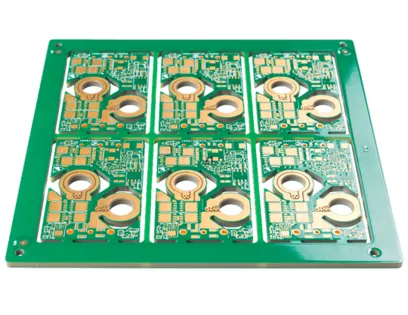

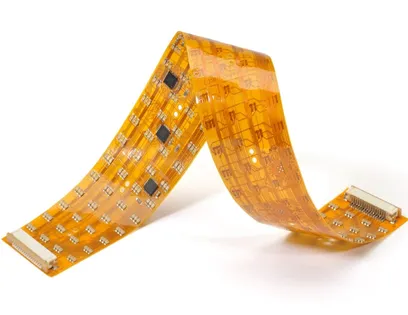

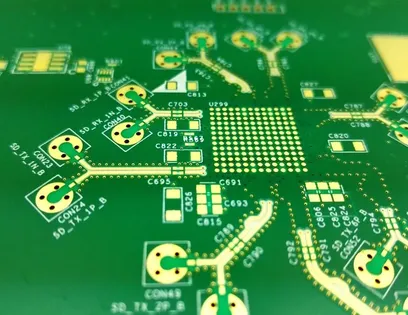

Modern industrial automation demands PCBs that can withstand harsh environments while maintaining absolute precision. At AIVON, we understand that industrial control systems—from robotics to PLC modules—require boards capable of enduring extreme temperatures, vibrations, and continuous 24/7 operation. We specialize in high-reliability, thick-copper, and multilayer PCBs designed to ensure rugged durability and signal integrity. Our manufacturing process guarantees that your mission-critical equipment remains operational, minimizing downtime and maximizing efficiency in complex industrial settings.

.webp)