Plays a critical role in medical monitoring instruments, pacemakers, MRI machines, and other equipment. Its high stability and reliability ensure device accuracy and safety, helping improve diagnostic and therapeutic outcomes.

Advanced materials for high-frequency, high-speed, and reliable electronic designs across communication, aerospace, and automotive industries.

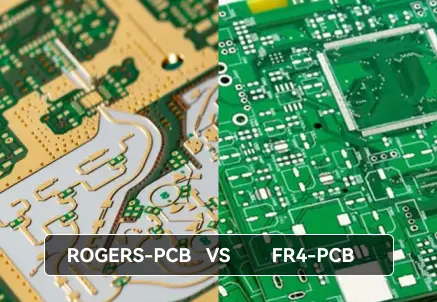

Rogers PCBs are printed circuit boards made from high-performance materials produced by Rogers Corporation. They represent a major breakthrough in high-frequency PCB technology for global wired and wireless communication products, delivering exceptional performance. Their main application areas include high-frequency PCBs, wireless base station PCBs, aerospace and defense, automotive electronics, and high-frequency or high-speed electronic devices.

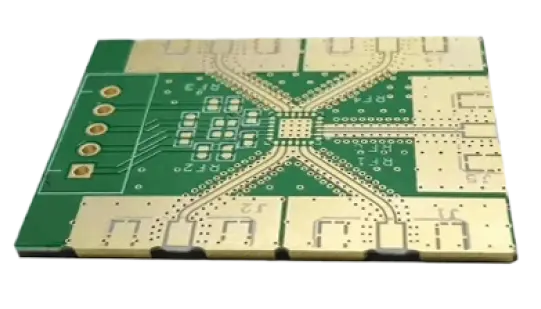

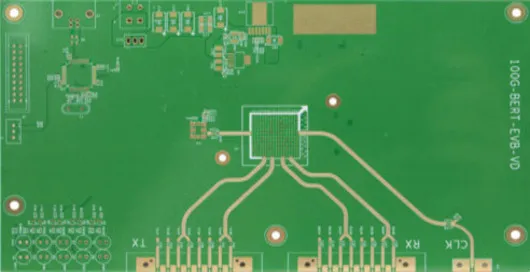

High-performance RO4350B material printed circuit board

Layers:2

Finished Board Thickness:1.6 mm

Material: RO4350B

Surface Finish:ENIG (Electroless Nickel Immersion Gold)

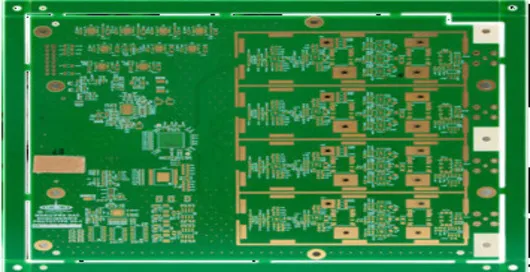

12-Layer RF PCB using Panasonic R5775G and Lianmao IT180 high-speed materials, manufactured with hybrid lamination, embedded resistors, and ENIG surface finish technology. Widely used as RF antennas in communication equipment.

Layers:12

Board Thickness:1.7 ± 0.17 mm

Minimum Hole Diameter:Mechanical via 0.2 mm

Minimum Line/Space:110/90 μm

Minimum Board Thickness to Hole Ratio:8.5:1

Materials:RO4350B + TU-768

Surface Roughness:ENIG 0.05 μm

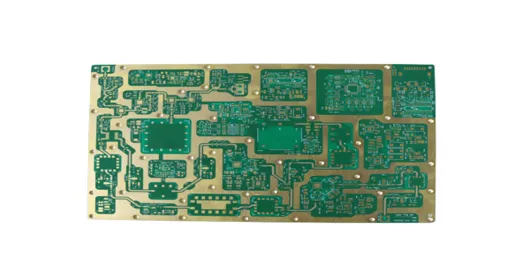

Designed for electronic devices with high functionality and high integration.

Layers:6

Material:FR4 + Rogers

Surface Finish:ENIG (Electroless Nickel Immersion Gold)

Minimum Drill Diameter:0.1 mm

Minimum Line Width:0.3 mm

Minimum Line Spacing:0.3 mm

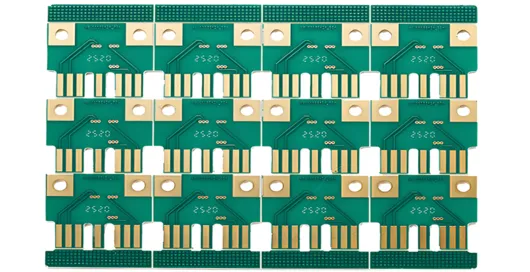

Manufactured usingRO4350B + TU768materials with hybrid lamination, mechanical drilling, and ENIG surface finish. Supports aminimum via diameter of 0.2 mmandminimum line/space of 100/100 μm.

Layers:4

Board Thickness:1.6 mm

Minimum Hole Diameter:0.2 mm

Minimum Line/Space:100/100 μm

Materials:RO4350B + TU768

Surface Roughness:ENIG 0.05 μm

Rogers PCBs feature extremely low dielectric loss, typically less than0.0027 at 10 GHz. Low dielectric loss ensures higher efficiency in high-frequency applications, minimizing energy waste and heat generation, preserving signal integrity—especially important for high-power and long-duration operation devices.

Rogers PCBs have aCTE (Coefficient of Thermal Expansion) typically between8–20 ppm/°C, helping maintain board stability in environments with temperature fluctuations. With a very low moisture absorption rate of0.02%, they maintain stable performance even in high-humidity conditions, preventing degradation or failure caused by moisture.

Rogers PCBs support operation from low MHz to high GHz frequencies, ensuring reliable performance in RF, microwave, 5G, and high-speed digital applications. Their consistent dielectric properties across the frequency spectrum enable precise signal transmission with minimal loss.

The dielectric constant generally ranges from2.2 to 10.2, depending on the model and material composition, for example, RT/duroid 5880 has a dielectric constant of2.20 ± 0.02 at 10 GHz. The stable dielectric constant across a wide frequency range aids in precise impedance control, ensuring consistent circuit performance.

Rogers PCB materials are strong and durable, with atensile strength exceeding 16,000 psi (110 MPa). They withstand significant mechanical stress, maintaining structural integrity and circuit stability in high-stress environments, reducing the risk of failures caused by mechanical strain.

The smooth copper and prepreg surfaces of Rogers PCBs allow precise etching and plating, supporting high-density interconnects and fine-pitch components. This ensures high manufacturing accuracy and reliable electrical connections in advanced circuits.

Plays a critical role in medical monitoring instruments, pacemakers, MRI machines, and other equipment. Its high stability and reliability ensure device accuracy and safety, helping improve diagnostic and therapeutic outcomes.

Widely used in automotive radar systems (e.g., 77 GHz radar), Advanced Driver Assistance Systems (ADAS), Vehicle-to-Everything (V2X) communication, in-car navigation, audio systems, and body control modules.

Core components for high-frequency antennas and base station antennas. Stable dielectric properties and excellent thermal stability ensure efficient operation even in complex environments. Suitable for high-speed backplanes, servers, and data centers, ensuring data signals are transmitted with minimal loss and maximum integrity.

Widely used in radar systems, avionics, communication modules, and mission-critical control units. Their low dielectric loss, stable dielectric constant, and excellent thermal and mechanical stability ensure reliable performance under extreme temperatures, vibration, and high-frequency conditions.

In contrast, FR4 materials are more cost-effective and suitable for standard consumer electronics or general-purpose PCBs. While FR4 can handle moderate frequencies and mechanical loads, its higher dielectric loss, variable dielectric constant, and lower thermal stability make it less suitable for demanding high-speed or high-frequency applications.