Used in fast-charging adapters, laptop power adapters, backlight driver boards for LCD TVs, and light source control boards for projectors.

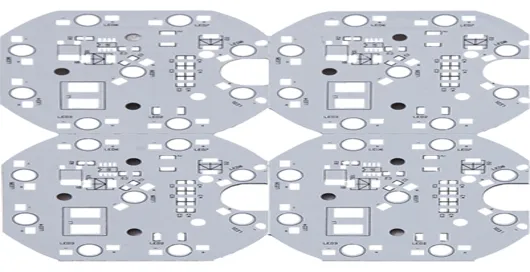

We specialize in high-quality aluminum PCB manufacturing and turnkey assembly for various industrial.

Aluminum PCB is a cost-effective heat dissipation circuit board constructed with high-purity aluminum (≥99.6%) as the thermal substrate, combined with low thermal resistance insulating media (thermal silicone gel, aluminum oxide ceramics, or modified epoxy resin) and conductive copper foil. Through an integrated design featuring rapid heat conduction via the aluminum core layer and electrical isolation via the insulating layer, it effectively addresses heat dissipation challenges for medium-power devices. It serves as the mainstream thermal substrate in fields such as LED lighting, power electronics, and automotive electronics.

MLT-002: Aluminum base, copper foil, FR4 glass cloth (Tg 130-170)

MLT-003: Aluminum base, copper foil, Laird non-woven fiber (Thermal conductivity 3.0 W/(m·K))

MLT-004: Aluminum base, copper foil, non-woven fiber (Bergquist), thermal conductivity 20 W/(m·K)

MLT-005: Aluminum base, copper foil, non-woven fiber, heat resistance 350°C for 10 min, dielectric constant 4.2

MLT-006: Aluminum base, copper foil, no glass fiber (Bergquist), thermal conductivity 2.0 W/(m·K).

MLT-007: Thick copper foil (40z-100z) laminate, high current. High-power circuits.

Aluminum alloy substrate rapidly conducts heat, effectively dissipating electronic component temperatures to prevent overheating damage.

Reduces heat buildup, delays component aging, extends circuit lifespan, and lowers failure rates.

Aluminum substrate provides superior durability and resistance to mechanical stress compared with standard FR4 boards.

Aluminum offers low weight and high strength, ideal for compact installations that save space.

Simplifies additional cooling designs, reducing production and assembly costs.

The dielectric layer ensures strong insulation between the circuit and the metal base, improving overall circuit safety.

Used in fast-charging adapters, laptop power adapters, backlight driver boards for LCD TVs, and light source control boards for projectors.

Used in driver boards for automotive LED headlights (low beam, high beam) and control boards for interior ambient lighting.

Used in low-voltage control circuits for frequency converters, signal amplification boards for sensors, small-to-medium switch-mode power supplies, and auxiliary circuit boards for uninterruptible power supplies (UPS).

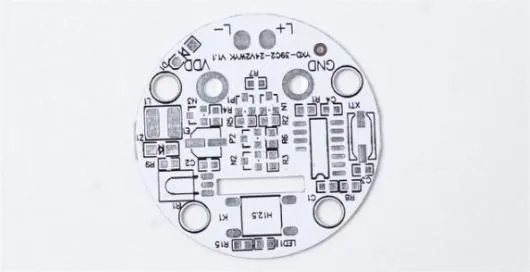

Used in LED ceiling lights, downlights, spotlights, LED street lights, tunnel lights, and garden lights.

Used in power converters, voltage regulators, and industrial control systems to ensure efficient thermal management and long service life.

Used in base stations, signal transmitters, and network equipment to enhance performance and reliability.

.webp)

The circuit layer serves the same function as that on a conventional PCB. It is made of high-quality copper foil with a thickness typically ranging from 1 oz to 10 oz, ensuring reliable conductivity and superior current-carrying capability.

The dielectric layer is a thermally conductive insulation material with low thermal resistance, which plays a key role in transferring heat from electronic components to the base. It is usually made from a polymer filled with special ceramics, offering excellent viscoelasticity, strong resistance to thermal aging, and the ability to withstand high thermal stress.

The base layer consists of aluminum, providing a solid mechanical foundation and exceptional heat dissipation performance. This structure allows components to maintain stable operation under high-power or high-temperature conditions, significantly improving product reliability and extending service life.