Used in critical components such as automotive ECUs, autonomous driving systems, and new energy battery management systems (BMS).

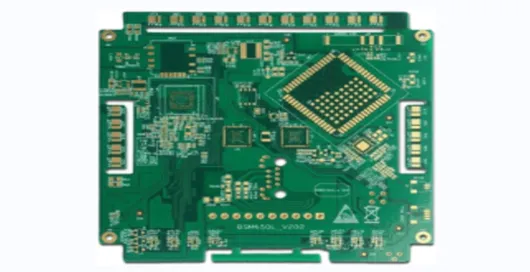

Superior Thermal Stability, Low Expansion, and Moisture Resistance for High-Performance Electronics

High TG PCBs feature a substrate Tg ≥170°C, offering excellent thermal stability, low Z-axis expansion, and superior moisture resistance. They withstand lead-free soldering at 260°C and perform reliably in high-temperature, high-pressure environments. Ideal for automotive ECUs, 5G base stations, and industrial inverters, these PCBs provide a robust foundation for high-performance and high-reliability electronic devices.

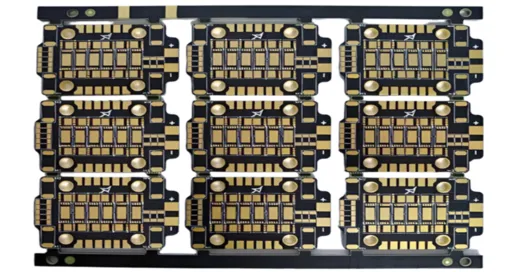

A technologically advanced multilayer printed circuit board designed for high-reliability and high-performance applications

Layers: 12

Board Thickness: 2.0 mm

Solder Mask: Matte Black

Minimum Hole Size: 0.2 mm

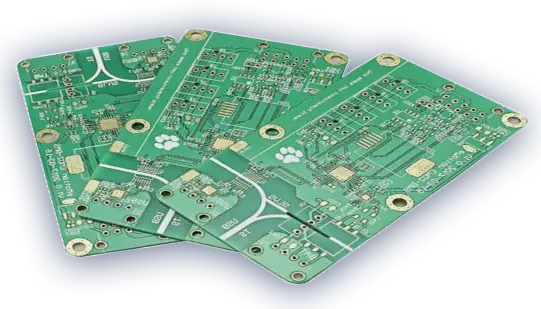

4-layer ENIG PCB for Renewable Energy Applications

Used in lithium battery storage, photovoltaic (PV) energy storage, and wind power storage systems.

Layers: 4

Material: FR4

Board Thickness: 1.6 mm

Surface Finish: ENIG (Electroless Nickel Immersion Gold)

Maintains strong mechanical stability even at high temperatures, resisting external stress effectively.

Low dielectric constant and low dissipation factor ensure minimal signal delay and high signal integrity in high-frequency transmission.

The high TG material minimizes thermal expansion differences between layers, supporting multilayer designs with fine traces and tight tolerances, crucial for aerospace, military, and high-power electronics.

Performs exceptionally under extreme temperature changes and humidity, suitable for demanding applications such as military and aerospace.

Meets RoHS and other environmental standards, helping to reduce ecological impact.

Advanced materials and precise fabrication reduce signal loss and crosstalk, supporting high-speed and high-frequency circuits with consistent performance in critical applications.

Used in critical components such as automotive ECUs, autonomous driving systems, and new energy battery management systems (BMS).

Applied in robot servo mainboards, power monitoring equipment, and automation control systems.

Used in 5G base station antennas, optical modules, and related devices.

Applied in ultrasound imaging machines, patient monitors, and other medical equipment.

Used in radar systems, avionics control units, satellite communication modules, and power converters.