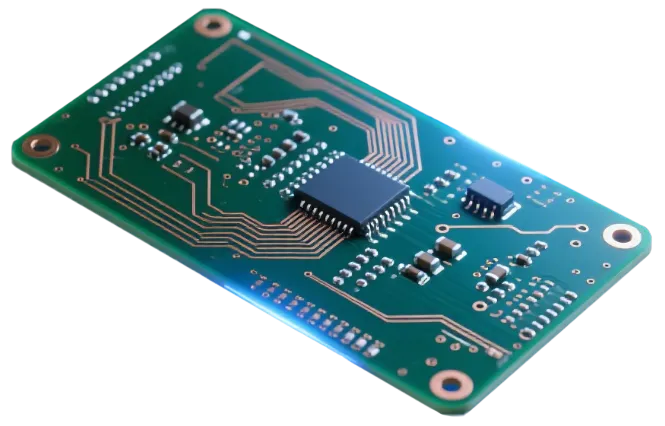

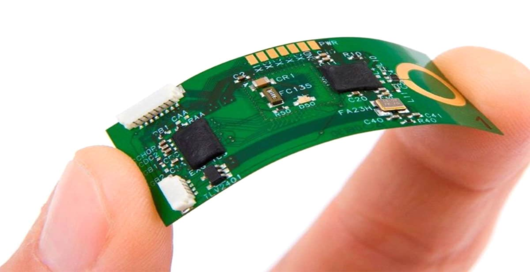

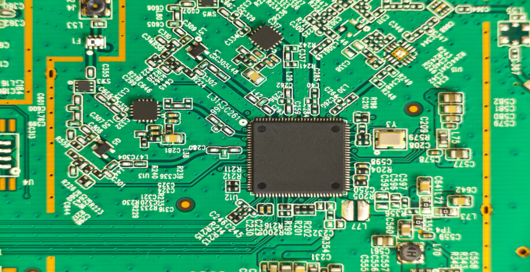

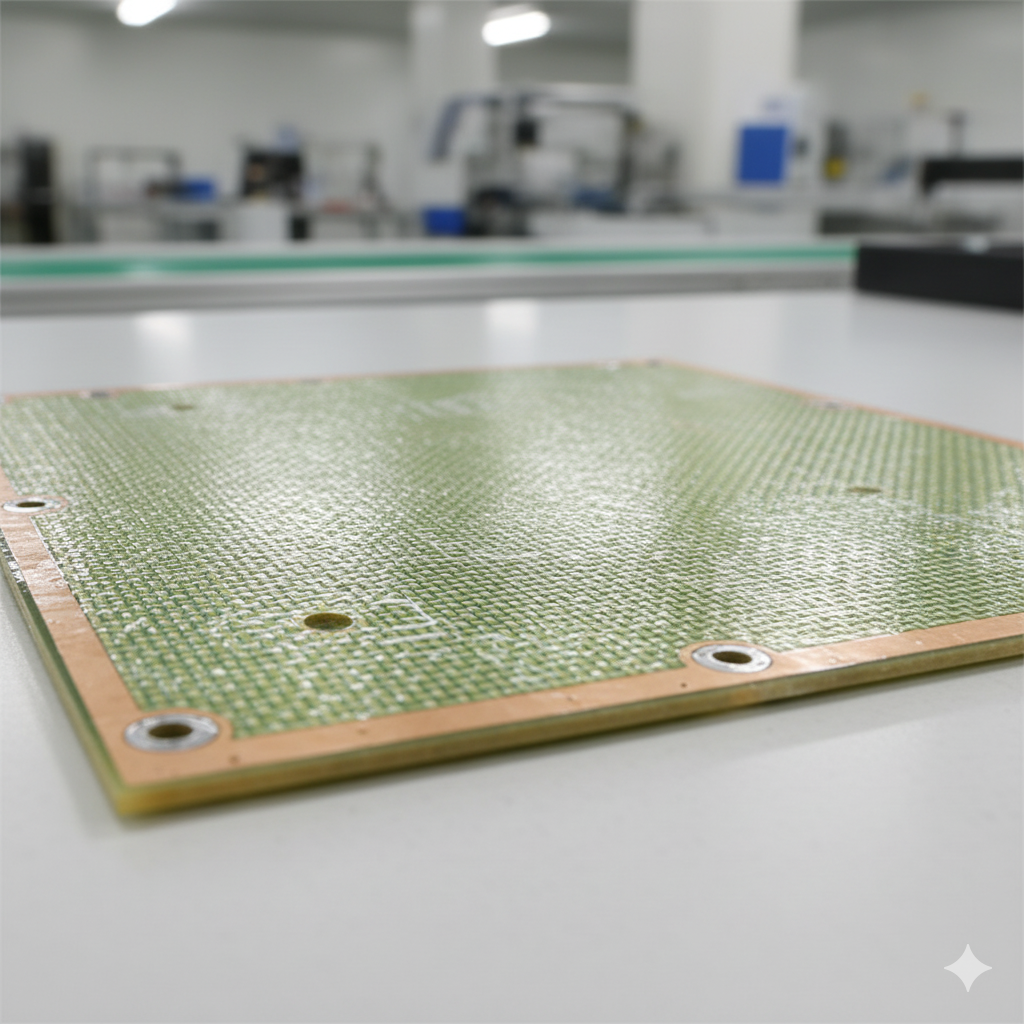

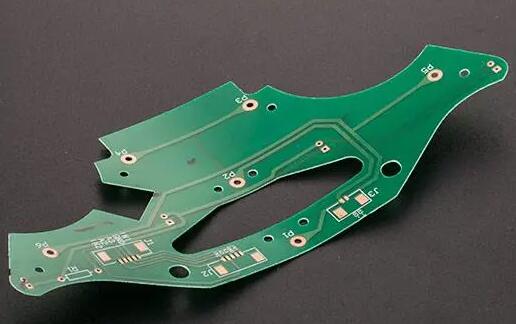

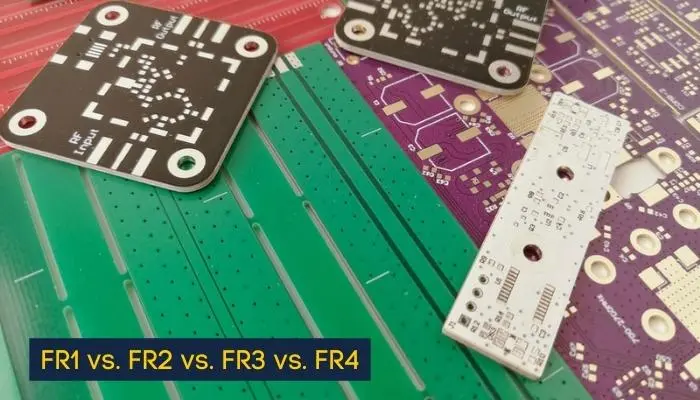

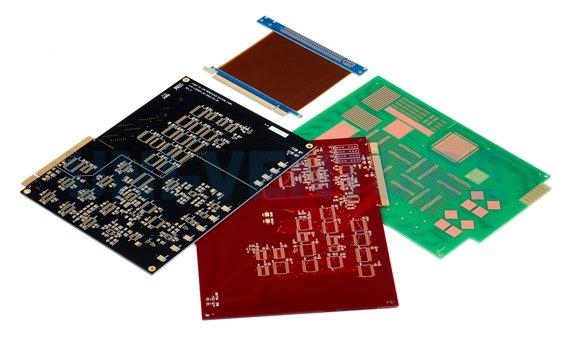

AIVON FR-4 PCBs enable compact designs in smartphones, laptops, and smart TVs, supporting up to 60 layers for high-density SMDs and BGAs. With low moisture absorption (<0.5%) and UL94 V-0 flame retardancy, they ensure safety and durability in daily use. Impedance control (50-100 ohms) preserves signal integrity for 5G and touch features, reducing device weight by 15% at 1.85 g/cm3 density. This cost-effective solution cuts prototyping expenses by 20%, fueling innovations in wearables and IoT devices for seamless connectivity.