Printed circuit boards rely on base materials for structural integrity and performance. Among fiberglass and paper-based options, FR1, FR2, FR3, and FR4 stand out as common choices. These flame-retardant grades balance cost, thermal stability, and mechanical strength in manufacturing. FR4 dominates due to its versatility in multilayer designs. In contrast, FR1 and FR2 suit simple applications with budget constraints. FR3 bridges the gap for moderate demands. Factory processes align material selection with IPC standards to ensure reliability. This guide compares these material types for PCBs. It highlights properties and selection criteria from a production perspective. Engineers and procurement teams find actionable insights here. Proper choices reduce defects and optimize yields in assembly lines.

What Are FR1, FR2, FR3, and FR4 Materials and Why They Matter

Base materials form the core of PCBs. They provide insulation and support for copper traces. FR grades indicate flame retardancy per UL 94 V-0. IPC-4101B defines specifications for these laminates in rigid boards.

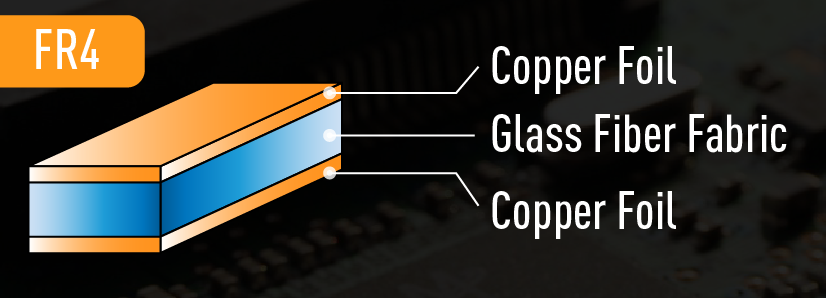

FR1 uses phenolic resin with cellulose paper. It offers low cost for single-sided boards. FR2 employs phenolic with cotton paper for slight mechanical gains. FR3 shifts to epoxy resin on paper for better heat resistance. FR4 integrates epoxy with woven glass fabric for superior durability.

These material types matter in manufacturing. They influence thermal expansion and solderability. Mismatched selections cause warpage during reflow. Factories prioritize FR4 for high-density interconnects. Paper-based options like FR1 cut expenses in low-frequency uses. Standards ensure consistency across suppliers. Adherence to IPC-4101B prevents failures in field applications. Selection drives yield rates and compliance with class 2 or 3 requirements per IPC-6012E.

Technical Principles Behind FR1, FR2, FR3, and FR4

Composition and Reinforcement

Laminate construction follows resin impregnation of reinforcement fibers. Heat and pressure cure the stack into rigid sheets. IPC-4101B specifies grades like /01 for FR1 and /04 for FR4.

FR1 and FR2 use paper substrates. Phenolic resin binds fibers for insulation. Paper provides flexibility but limits thickness control. FR3 upgrades to epoxy resin on paper. This improves adhesion during lamination. FR4 employs E-glass cloth. Woven strands offer tensile strength beyond paper options.

Glass transition temperature marks resin softening. FR1 and FR2 exhibit lower thresholds. This restricts use in elevated temperatures. FR3 and FR4 maintain stability longer. Coefficient of thermal expansion varies by reinforcement. Glass in FR4 minimizes board distortion.

Electrical and Thermal Properties

Dielectric constant affects signal integrity. Paper-based FR1 to FR3 show higher values than FR4. This suits low-speed signals. FR4's lower constant supports high-frequency designs. Flammability meets V-0 across grades via halogen additives.

Thermal conductivity remains low in all. PCB FR4 material dissipates heat better through glass paths. Manufacturing tests per IPC-TM-650 verify these traits. Electrolytic delamination assesses moisture resistance.

Mechanical Integrity

Tensile strength peaks in FR4 due to fiberglass. Paper alternatives like FR1 flex under stress. This impacts via drilling accuracy. FR3 offers compromise for cost-sensitive builds. IPC-4101B outlines peel strength for copper adhesion.

Related Reading: What are the Key Differences of FR1 vs. FR2 vs. FR3 vs. FR4?

Practical Solutions and Best Practices for Material Selection

Choose PCB materials by assessing design constraints. Evaluate layer count, operating temperature, and budget. FR4 fits most multilayer needs. Opt for FR1 in prototypes to control costs.

In factories, qualify laminates against IPC-4101B slash sheets. Request certificates for grade compliance. Test samples for Tg via differential scanning calorimetry. This confirms suitability for lead-free soldering.

- Design Integration: Specify material in stack-up drawings. Use FR4 for boards over four layers.

- Supplier Vetting: Verify UL listings for flame retardancy. Avoid generic calls; reference exact IPC grades.

- Process Compatibility: Pair FR3 with wave soldering. Reserve FR4 for reflow to leverage thermal margins.

Document selections in fabrication notes. Pilot runs expose warpage risks in FR1. Adjust via fill for paper-based types. Factories report stable yields with FR4 in 90 percent of high-volume orders.

For environmental compliance, select halogen-free variants under IPC-4101B/126. This aligns with RoHS without performance loss.

Related Reading: Material Matters: Selecting the Best Laminates for High-Frequency Multilayer PCBs

Insights from the Manufacturing Floor

Production lines reveal material behaviors under scale. FR1 panels absorb moisture faster than FR4. This demands extended bake times before etching. Factories mitigate with humidity-controlled storage.

FR2's cotton base resists tearing during routing. Yet, it yields dustier edges than glass. Vacuum systems handle residues effectively. FR3 bridges gaps in double-sided runs. Its epoxy enhances solder mask adhesion over phenolics.

A common challenge involves delamination in FR1 under thermal shock. IPC-TM-650 method 2.4.24 tests reveal weaknesses. Solutions include precise pressure control at 200 psi. FR4's glass weave prevents such issues in 95 percent of cycles.

For high-density boards, FR4 variants with higher Tg reduce z-axis expansion. Manufacturing data shows fewer vias failing post-reflow. Feedback from assembly confirms FR3's viability for automotive prototypes. These observations guide iterative improvements. Adhering to IPC-A-600J acceptability criteria standardizes inspections.

Conclusion

FR1, FR2, FR3, and FR4 represent key materials for types of PCBs. Each suits specific fiberglass or paper reinforcements based on needs. FR4 excels in demanding applications with robust properties. Simpler grades like FR1 control costs for basic designs. Factory alignment with IPC-4101B ensures optimal outcomes. Selection influences everything from lamination to reliability. Teams benefit from early specification reviews. This approach yields durable boards across production scales.

FAQs

Q1: What distinguishes FR1 from FR2 in PCB material types?

A1: FR1 uses cellulose paper with phenolic resin for basic insulation. FR2 incorporates cotton paper for improved mechanical strength. Both share low thermal thresholds but FR2 handles punching better. Factories prefer FR2 for telecom boards requiring durability. IPC-4101B grade /02 verifies FR2 compliance. This choice reduces edge cracks in routing.

Q2: How does FR3 compare to FR4 for fiberglass-reinforced PCBs?

A2: FR3 employs paper with epoxy for moderate heat resistance. FR4 uses woven glass for superior tensile and thermal stability. FR3 suits double-layer designs under budget limits. FR4 dominates multilayer production. Manufacturing tests show FR4 minimizing warpage in reflow. Select per IPC-4101B slash sheets for consistent performance.

Q3: Why choose FR4 over FR1 for high-reliability applications?

A3: FR4 provides glass reinforcement for low expansion and high strength. FR1's paper base limits it to low-stress uses. FR4 supports complex routing and soldering. Factories observe fewer defects in FR4 runs. IPC-6012E performance specs guide qualification. This ensures longevity in consumer electronics.

Q4: What factors influence selecting FR2 or FR3 in PCB manufacturing?

A4: Consider layer count and temperature exposure. FR2 fits single-sided with cost focus. FR3 extends to moderate multilayer via epoxy gains. Evaluate signal speed for dielectric needs. Production lines test via IPC-TM-650 for adhesion. Balanced choices optimize yields without excess expenses.

[Reference 1] IPC-4101B — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2006.

[Reference 2] IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2015.

[Reference 3] IPC-A-600J — Acceptability of Printed Boards. IPC, 2019.