Widely used in smartphones, tablets, laptops, and wearable devices, offering compact design, high routing density, and stable signal performance for complex electronic circuits.

AIVON offers precision-engineered 8-layer PCBs with optimized signal routing, controlled impedance, and multilayer thermal management for high-speed and high-density electronics.

.webp)

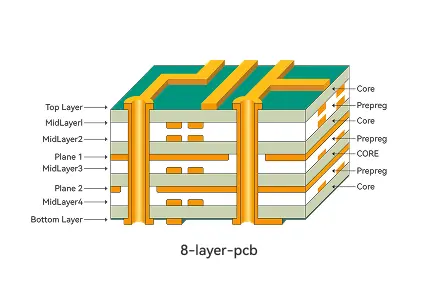

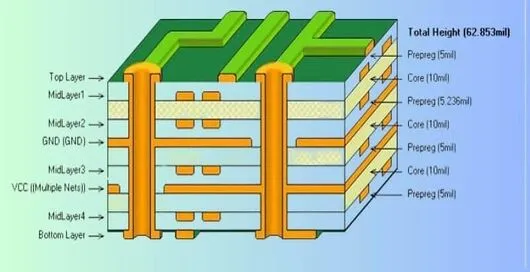

An 8-layer PCB is a multilayer printed circuit board that consists of eight conductive copper layers, typically arranged with alternating signal and plane layers for power and ground. This configuration allows for high-density routing, improved signal integrity, and reduced electromagnetic interference (EMI), making it suitable for complex, high-speed electronic designs.

AIVON’s 8-layer PCBs feature a carefully balanced layer structure, with signal, power, and ground layers strategically arranged to reduce electrical noise and enhance mechanical stability. This thoughtful layer distribution simplifies complex routing and improves overall circuit reliability. By providing clear separation between high-speed signals and power planes, these PCBs support advanced designs while maintaining consistent performance across all layers. The architecture is particularly suitable for high-density electronic systems in telecommunications, computing, and industrial automation.

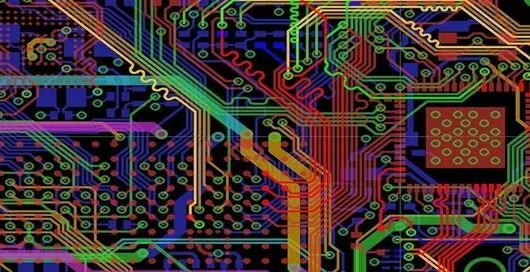

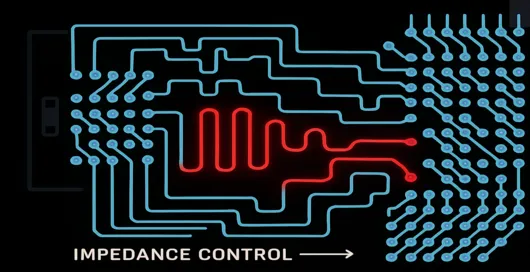

The multilayer configuration allows designers to route a high density of traces efficiently while keeping signal paths short. Controlled impedance traces are meticulously designed to prevent signal reflection, timing delays, and cross-talk. This ensures reliable data transmission even in high-speed and high-frequency circuits. Applications such as 5G communication modules, server boards, and automotive control units benefit from enhanced routing efficiency and reduced design complexity.

Dedicated ground planes in the inner layers act as effective shields against electromagnetic interference. When combined with impedance-controlled routing, this configuration ensures stable signal integrity for high-speed digital circuits and RF applications. Engineers can rely on consistent signal quality in environments that are sensitive to noise, such as communication equipment, radar systems, and precision instrumentation.

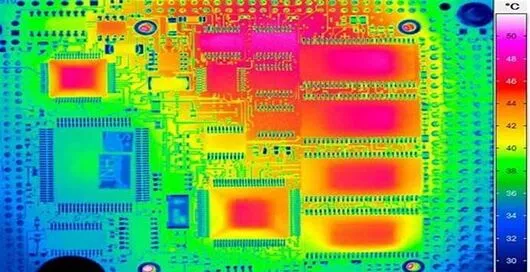

Thermal vias, optimized copper planes, and layer stacking strategies enhance heat dissipation across the PCB. This keeps critical components within safe operating temperatures, maintaining stable electrical performance under high power loads. Effective thermal management extends the lifespan of components and reduces the risk of overheating in demanding applications, including industrial machinery, aerospace systems, and high-performance computing devices.

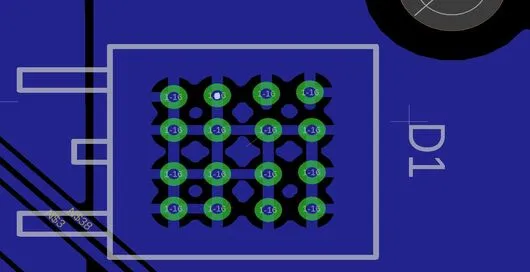

AIVON utilizes through-hole, blind, and buried vias to interconnect PCB layers efficiently. The selection of via type is based on current-carrying requirements, signal speed, and manufacturability considerations. This versatile approach ensures reliable vertical interconnections while supporting complex high-pin-count components such as BGAs and CSPs. It allows engineers to achieve dense designs without compromising electrical performance or long-term reliability.

Widely used in smartphones, tablets, laptops, and wearable devices, offering compact design, high routing density, and stable signal performance for complex electronic circuits.

These PCBs support advanced automotive systems such as engine control units (ECUs), infotainment systems, and ADAS modules, providing reliability under high temperatures and vibration conditions.

Ideal for diagnostic equipment, monitoring devices, and portable medical instruments, ensuring precision, signal integrity, and compliance with stringent safety standards.

Used in routers, switches, and wireless communication devices, these PCBs deliver low EMI, controlled impedance, and stable high-speed signal transmission for robust network performance.

These PCBs enable compact and reliable control boards for automation, robotics, and power management equipment, supporting durable operation in harsh industrial environments.