PCB Prototype

Trusted by engineers worldwide. AIVON provides efficient and high-quality PCB prototypes.

Trusted by engineers worldwide. AIVON provides efficient and high-quality PCB prototypes.

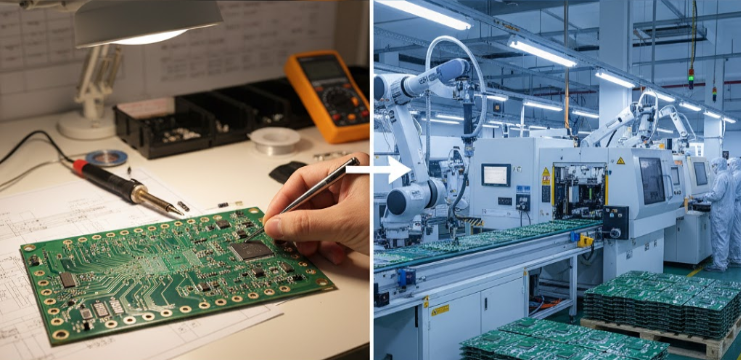

PCB prototyping is a critical step before mass production, allowing engineers to verify circuit design, test functionality, and identify potential issues early. At AIVON, we provide fast and precise prototype manufacturing that helps you accelerate product development, reduce risks, and ensure reliable performance for every design iteration.

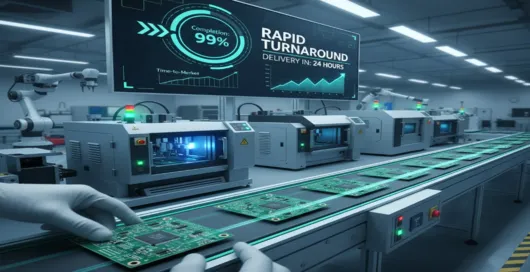

AIVON delivers fast prototype production with lead times as short as 24 to 72 hours. This rapid delivery allows engineers to significantly shorten design cycles, validate concepts quickly, and accelerate time to market. Our streamlined production workflow ensures that every order is handled efficiently while maintaining the highest standards of quality and consistency. This speed is particularly beneficial for projects with tight deadlines or iterative design processes, enabling teams to test and refine multiple prototypes without delays.

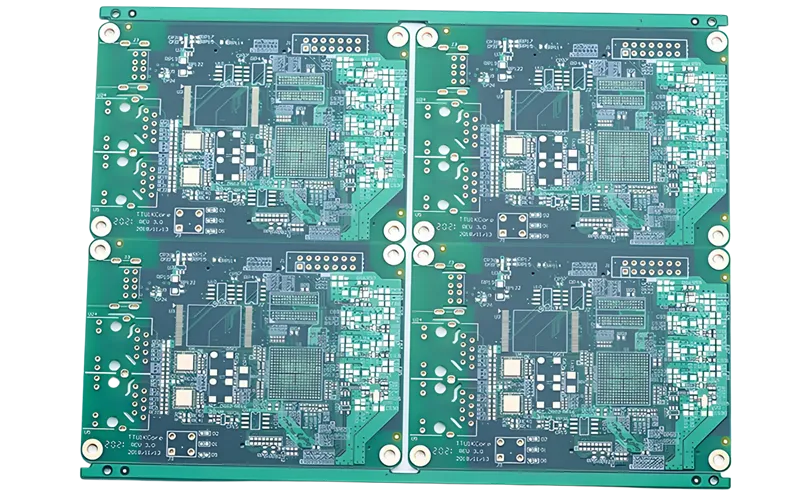

With state-of-the-art manufacturing equipment and advanced process control, AIVON guarantees exceptional trace accuracy, precise impedance control, and superior board reliability. Each prototype undergoes rigorous quality checks including 100 percent electrical testing and automated optical inspection. These measures ensure that every PCB meets exacting specifications and performs reliably in both prototype testing and subsequent production stages, giving engineers confidence in their design integrity.

AIVON’s experienced engineering team provides detailed Design for Manufacturability analysis to identify potential issues early in the design process. We offer professional guidance and optimization recommendations to ensure that your PCB design is manufacturable, cost-effective, and fully optimized for both prototyping and large-scale production. Our collaborative support helps reduce iteration cycles, minimize rework, and improve overall product reliability.