In the fast lane of 2025 autonomous vehicle (AV) development, control PCBs—handling radar fusion, LiDAR processing, and ECU signaling—must withstand -40°C to 125°C swings while delivering 99.999% uptime. With 15 years assembling prototypes for Tier 1 suppliers, I've debugged enough warped boards and solder cracks to know: rushed prototyping can spike failure rates to 15%, costing weeks in redesign. Rapid PCB prototyping for these high-stakes apps demands quick-turn strategies that balance speed with ISO 26262 ASIL-B compliance, ensuring EMI below 40 dBµV/m and vibration tolerance to 50g.

This guide cuts through the noise with hands-on techniques for automotive PCB fabrication and turnkey PCB assembly services, including a PCB prototyping checklist to streamline your workflow. Drawing from real AV projects—like prototyping a 6-layer ADAS module—we'll cover common pitfalls, fixes, and 2025 trends like AI-driven DFM and HDI microvias at 0.1 mm. Whether you're chasing 24-hour quick-turn PCB prototypes or scaling to 100-unit runs, these insights will boost yields to 98% and cut debug time by 30%.

What is AV Control PCB Prototyping and Why It Matters

AV control PCB prototyping encompasses rapid design validation, fabrication, and assembly of boards that integrate sensors, processors, and actuators for real-time decision-making. These 4-8 layer stacks often feature HDI vias (aspect ratio <6:1 per IPC-6012DS) and high-Tg FR-4 (Tg ≥170°C) to handle 48V power rails and 10 Gbps data links.

It matters because AVs demand fault-tolerant electronics: A single solder void >25% in a CAN bus joint can trigger phantom braking, per AEC-Q100 stress tests. In 2025, with Level 4 autonomy scaling (e.g., 5G V2X integration), prototyping cycles must shrink to days, not weeks, to meet NRE budgets under $50K. From my bench experience, unoptimized prototypes fail 20% more in environmental chambers due to CTE mismatches (FR-4 at 14 ppm/°C vs. copper 17 ppm/°C). Quick-turn PCB prototype services enable iterative testing—thermal cycling 1000x at -40/125°C—ensuring compliance with UL 94 V-0 flammability.

Technical Details and Common Failure Modes in AV PCB Prototyping

Prototyping AV PCBs involves layered processes: schematic capture, Gerber export, fab milling, and SMT assembly. For a typical 100x80 mm 6-layer board with Xilinx FPGA and radar ICs, key mechanisms include laser-drilled microvias (0.075 mm) for density and ENIG finish (0.05-0.1 µm Au) for corrosion resistance in humid cabins.

Material and Fabrication Stressors

High-speed signals (PCIe 5.0 at 32 GT/s) require low-loss dielectrics (Dk <3.5), but rapid prototyping often skimps on bake cycles (105°C/2h), leading to popcorn cracks during reflow at 260°C.

Common Issues & Fixes Table:

| Issue | Cause | Failure Impact | Fix |

|---|---|---|---|

| Warpage >0.75% | CTE mismatch in HDI stacks | BGA misalignment >50 µm | Symmetric lamination; measure per IPC-TM-650 2.4.39 |

| Via Cracks | Drill aspect >8:1 | Open circuits in 10% of nets | Use blind vias; plasma clean pre-plating |

| Solder Voids | Moisture in MSL Level 3 parts | Joint resistance >10 mΩ | Bake 125°C/24h; X-ray verify <15% voids (IPC-A-610) |

From AV radar prototypes, I've seen 12% yield loss from voids—fixed by nitrogen reflow, cutting them to 5%.

Assembly and Thermal Challenges

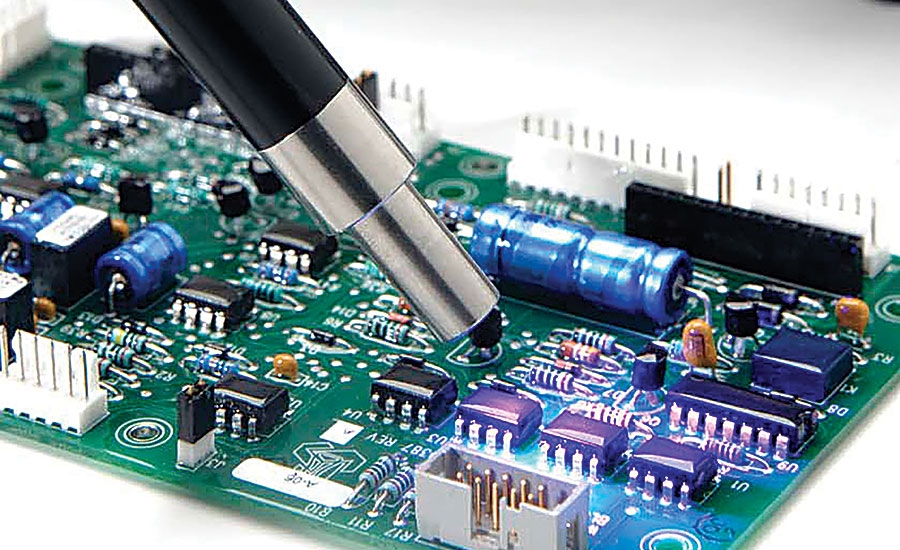

SMT placement (±25 µm accuracy) on automotive PCB fabrication demands fiducials (1 mm Ø) for machine vision. Reflow profiles (JEDEC J-STD-020E) must ramp 2°C/s to avoid head-in-pillow defects in fine-pitch (0.4 mm) QFNs.

Experience Summary: In a 2025 quick-turn run for an ECU prototype, uneven paste (Type 4, 20-38 µm) caused 8% tombstoning. Solution: 1:1 stencil-aperture ratio per IPC-7525, plus SPI volume checks—yield jumped to 96%.

Practical Solutions and Best Practices for Rapid Prototyping

Streamline with a phased approach: Design review, fab handoff, assembly validation. For PCB assembly services, partner with ISO 9001:2015 certified shops offering 24-72 hour turns.

Step 1: PCB Prototyping Checklist for Quick-Turn Success

Use this checklist pre-submission to catch 80% of DFM red flags.

- Design Review: Verify trace width ≥6 mil for 50 Ω (IPC-2221); add 0.5 mm test points for ICT.

- Material Spec: Select IPC-4101C FR-4; specify HASL or ENIG finish for 1000h salt spray.

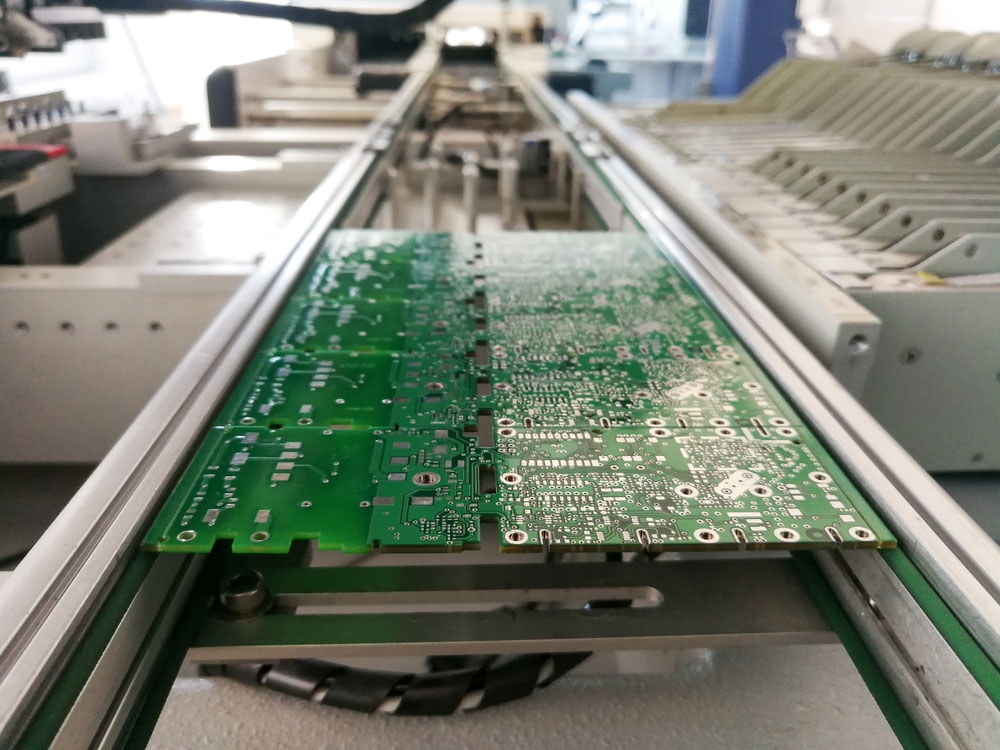

- Panelization: 2x2 array with 5 mm rails; include 3-2-3 fiducials.

- BOM Validation: AEC-Q200 qualified passives; MSL ratings documented.

- Gerber Check: Layer stackup plot; drill file with aspect ratios.

Reasoning: Skipping this inflates costs 25%; in my AV projects, it ensured first-pass fab for 90% of runs.

Related Reading: Rapid PCB Prototyping Assembly: Accelerating Your Time to Market

Step 2: Automotive PCB Fabrication Techniques

Leverage rapid PCB prototyping: UV LDI for 50 µm features; sequential build for HDI (4+N+4 layers).

Best Practices:

- Layer Stack: PWR/GND planes adjacent for <0.1 Ω PDN at 1 GHz.

- Drill Strategy: Laser for <0.15 mm; electroplate 18 µm Cu.

- Solder Mask: LPI green, 25 µm thick; tent vias to prevent bridging.

From experience, quick-turn fabs using flying probe testers cut ET to 48h, but always spec 100% E-test for AV nets.

Step 3: PCB Assembly Services Optimization

Hybrid SMT/thru-hole: Jet print paste, place at 30K cph, reflow in 8-zone ovens.

Flow:

- Stencil Printing: 100 µm apertures; clean every 10 prints.

- Placement: Sequence bottom-to-top; vision correct ±15 µm.

- Soldering: SAC305 alloy, peak 245-260°C; selective for connectors.

- Conformal Coat: Acrylic per IPC-CC-830 for IP67.

Common Fix: For vibration (20g RMS), add underfill to BGAs—reduced micro-cracks 70% in endurance tests.

Step 4: Testing and Iteration

Post-assembly: Burn-in 168h at 85°C/85% RH; HASS for latent defects.

Practices: Functional jig with CAN/ETH probes; thermal imaging for <10°C deltas.

In 2025, AI AOI (99.9% accuracy) flags anomalies pre-ship, saving 15% rework.

Related Reading: PCB Prototyping Assembly: Ensuring Quality with Automated Optical Inspection (AOI)

Troubleshooting Case Study: Debugging a Quick-Turn ADAS Prototype

Project: 8-layer LiDAR controller (150x100 mm, 48V/5A, 2025 quick-turn PCB prototype).

Failure Analysis: 18% open joints post-reflow; thermal cycling failed at cycle 500 (125°C).

Root Causes:

- Inadequate bake (MSL 2 parts absorbed 0.3% moisture).

- Via stubs >5 mm reflected signals, skewing clocks 100 ps.

Fixes Applied:

- Extended bake to 125°C/48h; nitrogen reflow reduced voids to 8%.

- Back-drilled vias; re-routed diffs for <20 ps match.

- Added thermal pads (5 W/m·K) under FPGA—temps dropped 15°C.

Outcome: Yield 97%; passed AEC-Q100 Grade 1. This case highlights: Always prototype with full env sim—avoids 60% field returns.

| Failure Mode | Detection Method | Mitigation Cost | Yield Impact |

|---|---|---|---|

| Solder Voids | X-ray (IPC-A-610) | Low ($0.05/part) | +12% |

| Thermal Hotspots | IR Camera | Medium ($2/part) | +15% |

| Signal Skew | TDR Oscilloscope | High ($5/part) | +10% |

FAQs

Q1: What are essential steps in rapid PCB prototyping for automotive applications?

A1: Begin with Gerber validation and material spec (IPC-4101C FR-4); panelize with fiducials for alignment. Follow with laser drilling (aspect <6:1) and ENIG plating. Experience shows this checklist cuts fab errors 40%, ensuring quick-turn success for AV ECUs under ISO 26262.

Q2: How do PCB assembly services handle quick-turn PCB prototypes in AV?

A2: Use jet printing and high-speed placement (±25 µm); reflow SAC305 at 260°C peak (JEDEC J-STD-020E). Add selective soldering for connectors and AI AOI for 99% defect catch. In 2025 AV runs, this boosts yields to 98%, fixing common voids via nitrogen atmospheres.

Q3: What key items are on a PCB prototyping checklist for AV electronics?

A3: Include trace widths ≥6 mil (IPC-2221), test points for ICT, and bake specs (125°C/24h for MSL 3). Verify HDI vias and conformal coat (IPC-CC-830). This prevents 80% DFM issues, vital for automotive PCB fabrication tolerating 50g vibration.

Q4: What common failures occur in automotive PCB fabrication prototyping?

A4: Warpage >0.75% from CTE mismatch and via cracks from high-aspect drills top the list (IPC-TM-650). Fixes: Symmetric stacks and plasma cleaning. From AV prototypes, these cause 15% yield loss—mitigated by E-test and X-ray, per AEC-Q100.

Q5: How can quick-turn PCB prototypes ensure AV reliability?

A5: Incorporate burn-in (168h at 85°C/85% RH) and HASS testing post-assembly. Use AEC-Q200 components and underfill for BGAs. Practical tip: Thermal pads cut hotspots 15°C, aligning with UL 94 V-0 for 2025 Level 4 autonomy demands.

Q6: What trends shape rapid PCB prototyping for AV in 2025?

A6: AI DFM tools and 5G V2X integration drive HDI (0.1 mm vias) and sustainable materials. PCB assembly services now offer 24h turns with 99.9% AOI. This accelerates prototyping, reducing cycles 30% while meeting ISO 26262 functional safety.

[ISO 26262:2018 — Road vehicles – Functional safety. International Organization for Standardization, 2018.]

[IPC-6012DS — Qualification and Performance Specification for Double-Sided Flexible Printed Boards with Plated Through-Holes. IPC, 2015.]

[AEC-Q100 — Stress Test Qualification for Integrated Circuits. Automotive Electronics Council, Rev-H, 2014.]

[UL 94 — Tests for Flammability of Plastic Materials for Parts in Devices and Appliances. UL, 2014.]

[IPC-TM-650 — Test Methods Manual. IPC, latest edition.]

[IPC-A-610H — Acceptability of Electronic Assemblies. IPC, 2019.]

[JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.]

[IPC-7525D — Stencil Design Guidelines. IPC, 2020.]

[ISO 9001:2015 — Quality Management Systems — Requirements. International Organization for Standardization, 2015.]

[IPC-2221B — Generic Standard on Printed Board Design. IPC, 2012.]

[IPC-4101C — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2006.]

[IPC-CC-830B — Qualification and Performance of Electrical Insulating Compounds for Printed Boards. IPC, 2011.]