Widely used in smartphones, tablets, laptops, and wearable devices, offering compact design, high routing density, and stable signal performance for complex electronic circuits.

Experience the next level of multilayer PCB manufacturing with AIVON — combining advanced materials, tight tolerances, and consistent quality for demanding electronics.

.webp)

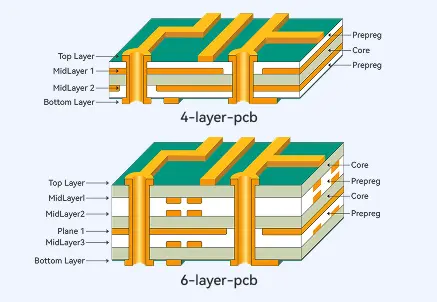

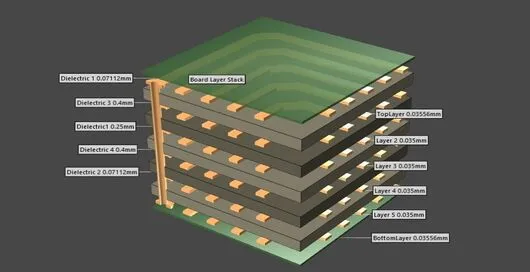

A 6-layer PCB is a type of multilayer printed circuit board that contains six conductive copper layers, usually arranged as four signal layers and two inner layers for power and ground planes. This structure provides improved signal integrity, noise reduction, and EMI control, making it ideal for high-speed and high-density electronic designs. The typical 6-layer PCB stackup follows a configuration such as Signal–Ground–Signal–Power–Signal–Signal, which allows for efficient routing and minimal interference between layers. AIVON specializes in manufacturing custom 6-layer PCBs with precise layer alignment, controlled impedance, and high-quality materials to ensure consistent electrical performance and long-term reliability.

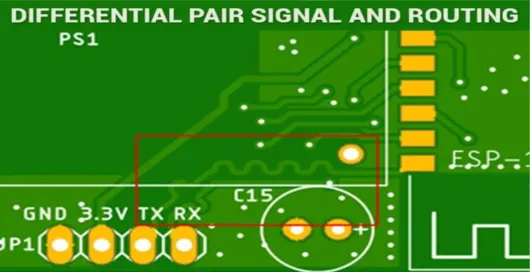

The flexible sections of multilayer PCBs can be bent, folded, and routed in three dimensions to navigate around internal obstacles within electronic devices. This design capability allows engineers to maximize internal space utilization and significantly reduce overall product size. For instance, the thickness of smartphones can be reduced by up to thirty percent, enabling slimmer and more portable designs. Flexible routing also helps maintain stable signal paths and reduces the risk of interference, making it ideal for high-speed and high-frequency applications.

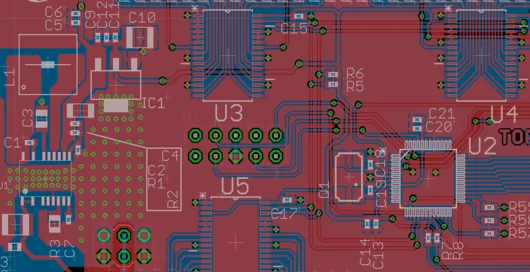

The addition of multiple layers in multilayer PCBs provides designers with greater routing capacity within a compact board area. This allows more signals to be routed efficiently, supporting high component density and complex circuit layouts. By accommodating sophisticated designs without the need for extra interconnects, multilayer PCBs enable smaller, more efficient electronic devices while ensuring reliable connectivity across all circuits. This capability is particularly valuable in consumer electronics, automotive modules, and advanced communication devices.

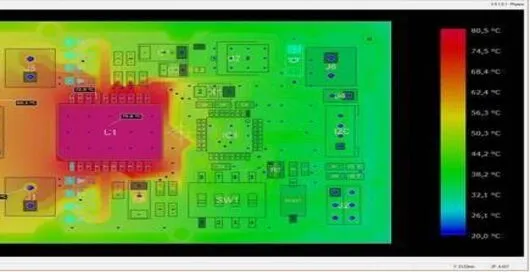

Dedicated inner planes in multilayer PCBs provide uniform power distribution and reduce voltage drops across the board. The multilayer construction also enhances heat dissipation, allowing efficient thermal management even under high-current or high-frequency conditions. These features improve electrical performance and ensure the PCB operates reliably in demanding environments. Applications such as industrial control systems, automotive electronics, and aerospace equipment benefit from this enhanced power integrity and thermal stability.

The multilayer configuration increases board rigidity, reducing warping and deformation during both manufacturing and operation. Enhanced mechanical strength ensures long-term durability in harsh conditions, including vibration, mechanical stress, and temperature fluctuations. Six-layer PCBs are particularly suitable for applications that demand robust performance and extended service life, such as aerospace systems, medical devices, and industrial machinery.

Widely used in smartphones, tablets, laptops, and wearable devices, offering compact design, high routing density, and stable signal performance for complex electronic circuits.

These PCBs support advanced automotive systems such as engine control units (ECUs), infotainment systems, and ADAS modules, providing reliability under high temperatures and vibration conditions.

Ideal for diagnostic equipment, monitoring devices, and portable medical instruments, ensuring precision, signal integrity, and compliance with stringent safety standards.

Used in routers, switches, and wireless communication devices, these PCBs deliver low EMI, controlled impedance, and stable high-speed signal transmission for robust network performance.

These PCBs enable compact and reliable control boards for automation, robotics, and power management equipment, supporting durable operation in harsh industrial environments.