Introduction

Six-layer printed circuit boards support complex electronics in compact forms. These boards integrate multiple signal and power layers for enhanced performance. As demands grow in sectors like telecommunications and computing, 6-layer PCB trends evolve rapidly. Innovations in materials and design address miniaturization needs. Future technology in 6-layer PCBs promises better signal integrity and efficiency.

This article examines key developments. It covers advanced materials, high-density interconnects, and embedded components. Engineers benefit from understanding these shifts to optimize designs. Procurement teams gain insights for reliable sourcing. AIVON provides guidance on aligning projects with emerging standards. Explore how these elements shape reliable assemblies.

What Is a 6-Layer PCB and Why It Matters

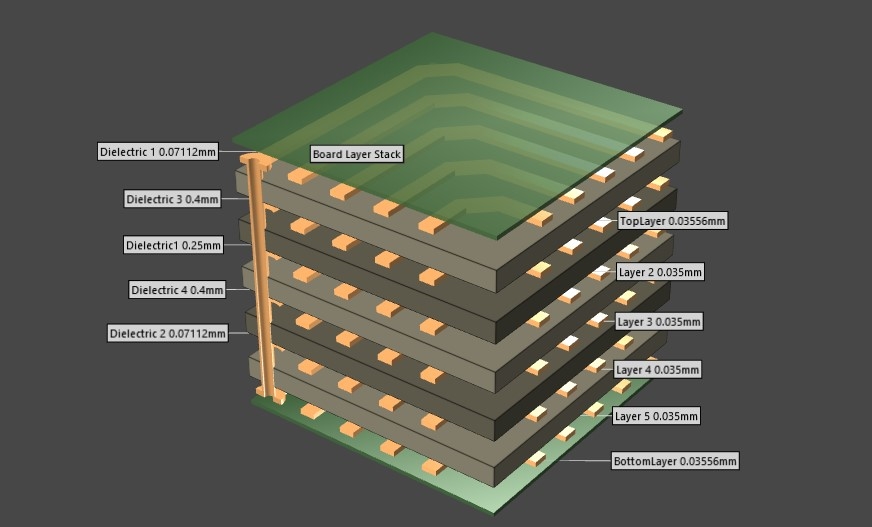

A 6 layer broad consists of six conductive layers separated by insulating dielectrics. It includes signal routing, ground planes, and power distribution. This configuration handles higher data rates than simpler boards. Standards like IPC-2221B outline design parameters for multilayer boards.

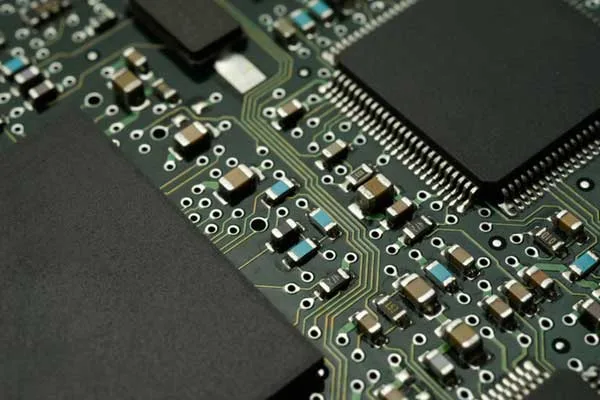

These PCBs matter in modern applications. They support 5G networks and Internet of Things devices. Increased layer count reduces crosstalk and improves electromagnetic compatibility. In automotive electronics, 6-layer boards manage sensor data flows. As devices shrink, these boards enable dense component placement.

Future relevance stems from performance demands. High-speed interfaces require controlled impedance. 6-layer PCB future technology integrates with artificial intelligence systems. Boards must withstand thermal cycles while maintaining flatness. Compliance with IPC-6012E ensures qualification for rigid multilayer use. Designers select these for balanced cost and capability.

Key Trends Shaping 6-Layer PCB Technology

Trends in 6-layer PCB technology focus on density and sustainability. Miniaturization drives adoption in consumer gadgets. Higher layer counts accommodate finer traces. Sequential lamination builds allow microvia integration.

Advanced Materials for Enhanced Performance

Advanced materials elevate 6-layer PCB advanced materials usage. Low-loss dielectrics reduce signal attenuation at gigahertz frequencies. High glass transition temperature resins withstand reflow peaks. IPC-4101F specifies base materials for rigid boards, including halogen-free options.

Developers favor polyimide for flexibility in rigid-flex hybrids. These materials offer thermal stability up to 260°C. Ceramic-filled composites improve heat dissipation in power sections. Sustainability pushes for recycled content without compromising dielectric constants.

Selection depends on application. For RF modules, low coefficient of thermal expansion matches components. Factory processes verify material uniformity per IPC-TM-650 2.5.5. These choices extend board life in harsh environments.

High-Density Interconnect Integration

High-density interconnect transforms 6-layer PCB high-density interconnect capabilities. HDI employs blind and buried vias for tighter routing. Microvias under 150 microns enable component proximity. IPC-6016D qualifies HDI PCBs for dense builds.

This trend supports ball grid array footprints. Stacked vias connect layers efficiently. Aspect ratios reach 1:1 for laser-drilled holes. Design rules limit via stubs to minimize reflections. Simulations predict eye diagrams for compliance.

In production, sequential buildup adds layers incrementally. This method controls registration accuracy. HDI reduces board size by 30% in compact devices. Applications include wearables and medical implants.

Embedded Components for Compact Designs

Embedded components redefine space usage in 6-layer PCB embedded components. Resistors and capacitors integrate into dielectrics. This approach frees surface area for active devices. IPC-7095D provides guidelines for embedded passives.

Polymer thick film prints circuits directly on layers. Capacitors form between power and ground planes. Inductors embed in magnetic cores for filters. Assembly skips surface mount for these elements.

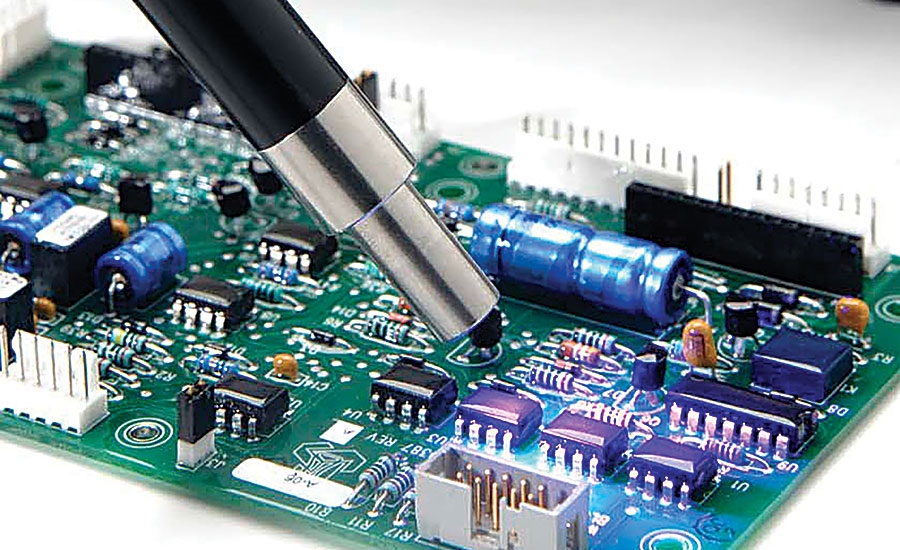

Benefits include shorter loops for noise reduction. Thermal management improves as heat spreads evenly. Challenges involve precise placement during lamination. Test methods per IPC-TM-650 2.6.7 verify functionality post-process.

Suggested Reading: Designing a 6-Layer PCB for EMI/EMC Compliance: A Comprehensive Guide

Innovations Driving the Future of 6-Layer PCBs

Innovations propel 6-layer PCBs toward smarter manufacturing. Additive processes like 3D printing prototype complex geometries. Aerosol jet deposition patterns conductive inks on curved surfaces.

Artificial intelligence optimizes stackups. Algorithms predict warpage from material properties. This reduces iterations in design cycles. Standards like IPC-2581C standardize digital data exchange for AI tools.

Flexible substrates blend with rigid sections for foldable electronics. Semi-flex designs route signals across bends. Power integrity tools simulate plane splits to avoid voltage drops.

Sustainability innovations include lead-free finishes and low-energy cures. Recyclable laminates lower environmental impact. Factories adopt closed-loop water systems for etching.

These advances align with ISO 14001 for environmental management. Procurement benefits from traceable supply chains. AIVON supports clients in selecting verified materials.

Industry Insights on 6-Layer PCB Applications

Applications highlight practical value. In networking gear, 6-layer boards handle 100G Ethernet. Dedicated planes shield differential pairs. Automotive ADAS systems embed sensors for real-time processing.

Medical devices use HDI for portable diagnostics. Embedded actives reduce battery drain. Aerospace demands high-reliability builds per IPC-6012DS Class 3.

One insight involves IoT gateways. Designers integrate antennas in inner layers for isolation. This setup meets FCC emissions limits. Troubleshooting focuses on via transitions for clean signals.

Future deployments target edge computing. Boards support machine learning inference with low latency. Balanced stackups ensure thermal uniformity.

Conclusion

The future of 6-layer PCBs blends density with efficiency. Trends in advanced materials and HDI meet rising demands. Embedded components enable sleeker profiles. Innovations like AI design streamline development.

Adopt these for competitive edges in electronics. Standards guide reliable outcomes. AIVON offers expertise in navigating these shifts. Stay informed to future-proof projects.

FAQs

Q1: What are the main 6-layer PCB trends for 2025?

A1: 6-layer PCB trends emphasize miniaturization and high-speed support. HDI vias enable denser routing. Sustainability drives halogen-free materials. AI tools optimize layouts for signal integrity. These align with applications in 5G and AI devices.

Q2: How do advanced materials impact 6-layer PCB future technology?

A2: Advanced materials in 6-layer PCB future technology lower losses and boost thermal performance. Low-Dk dielectrics suit RF signals. High-Tg resins endure assembly heats. IPC-4101F ensures material specs. Selection enhances reliability in compact builds.

Q3: Why integrate high-density interconnect in 6-layer PCBs?

A3: High-density interconnect in 6-layer PCBs packs more functions into small spaces. Microvias reduce trace lengths. This cuts crosstalk in high-speed designs. IPC-6016D sets performance benchmarks. It supports BGA components effectively.

Q4: What benefits come from 6-layer PCB embedded components?

A4: 6-layer PCB embedded components save surface space and shorten signal paths. Passives integrate seamlessly for noise control. This improves power efficiency. IPC-7095D outlines design rules. Applications gain from compact, reliable assemblies.

References

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2009.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2017.

IPC-4101F — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2017.

IPC-6016D — Qualification and Performance Specification for High Density Interconnect (HDI) Printed Boards. IPC, 2018.

IPC-7095D — Design and Assembly Process Implementation for Embedded Components. IPC, 2019.

IPC-TM-650 — Test Methods Manual. IPC, various revisions.

IPC-2581C — Printed Board/Printed Component Information and Traceability Specification. IPC, 2020.

ISO 14001:2015 — Environmental Management Systems. ISO, 2015.