Printed circuit boards depend on base materials for durability and function. FR1, FR2, FR3, and FR4 represent core grades in PCB production. These flame-retardant laminates vary in composition and performance. FR1 and FR2 use paper reinforcements for cost efficiency. FR3 adds epoxy for improved stability. FR4 employs fiberglass for high reliability. Factories select these based on thermal needs and layer complexity. Differences affect lamination, drilling, and assembly yields. Adherence to IPC standards ensures consistent quality. This article details key distinctions from a manufacturing viewpoint. It covers properties, applications, and selection strategies. Procurement teams and engineers access factory insights to match materials with designs. Optimal choices minimize defects and support scalable production.

What Are FR1, FR2, FR3, and FR4 and Why They Matter in PCBs

FR grades denote flame-retardant base materials for rigid PCBs. UL 94 V-0 certification confirms self-extinguishing properties. IPC-4101E outlines specifications for these laminates in board fabrication.

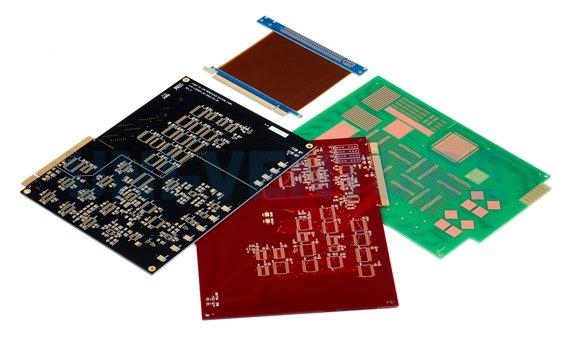

FR1 consists of phenolic resin on cellulose paper. It serves single-layer boards in low-cost electronics. FR2 upgrades to cotton paper with phenolic for better punchability. FR3 uses epoxy resin on cellulose paper for enhanced heat tolerance. FR4 features epoxy on woven glass fabric for multilayer strength.

These materials matter in manufacturing. They dictate thermal expansion and insulation. Poor matches lead to delamination during soldering. Factories favor FR4 for 80 percent of production due to its robustness. Paper-based FR1 to FR3 reduce expenses in simple designs. IPC-6012F sets performance benchmarks for rigid boards, including material integrity. Compliance supports class 3 reliability in aerospace and medical devices.

| Material | Reinforcement | Resin | Key Use Case |

|---|---|---|---|

| FR1 | Cellulose Paper | Phenolic | Consumer gadgets, single-sided |

| FR2 | Cotton Paper | Phenolic | Telecom panels, punchable |

| FR3 | Cellulose Paper | Epoxy | Automotive basics, double-sided |

| FR4 | Woven Glass | Epoxy | Servers, high-density interconnects |

This summary highlights core differences. Production data emphasizes FR4's role in yield stability.

Related Reading: Material Matters: Selecting the Best Laminates for High-Frequency Multilayer PCBs

Technical Principles of FR1, FR2, FR3, and FR4

Laminate Formation and Grades

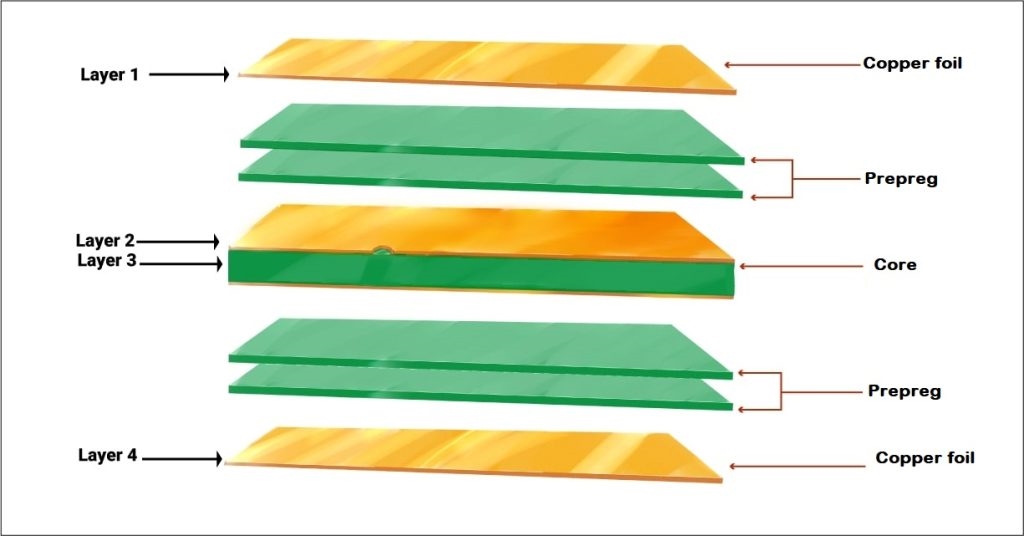

Laminate formation involves resin infusion into fibers followed by curing under heat and pressure. IPC-4101E slash sheets detail grades like /01 for FR1 and /24 for FR4.

Composition and Structure

FR1 and FR2 rely on paper cores. Phenolic resin provides binding and insulation. Cellulose in FR1 offers uniformity but low rigidity. Cotton in FR2 enhances tear resistance. FR3 replaces phenolic with epoxy on paper for chemical stability. FR4's E-glass weave delivers dimensional control.

Resin content influences cure cycles. Phenolics typically require 150 to 180 degrees Celsius. Epoxies in FR3 and FR4 extend to around 200 degrees Celsius for denser bonds.

Thermal and Electrical Characteristics

Glass transition temperature (Tg) defines heat deflection. FR1 and FR2 show Tg around 105 degrees Celsius. FR3 reaches roughly 130 degrees Celsius. FR4 standard grades hit about 135 degrees Celsius, with high-Tg variants at 170 degrees Celsius. This directly impacts reflow soldering limits.

Dielectric constant (Dk) measures signal propagation. Paper-based FR1 to FR3 typically exhibit Dk of 4.5 to 5.5 at 1 MHz. FR4 lowers to about 4.0 to 4.5 for improved high-speed performance. Dissipation factor (Df) follows the same trend, with FR4 minimizing dielectric losses. IPC-TM-650 tests validate these via thermal analysis. Moisture absorption affects Dk stability—FR4 commonly absorbs under 0.5 percent versus ~3 percent in FR1.

Mechanical Properties

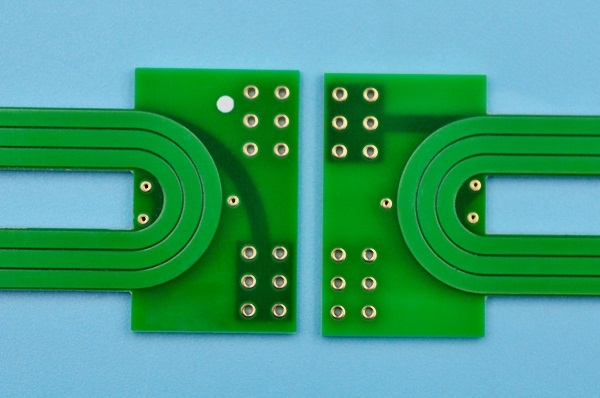

Tensile strength varies by reinforcement. PCB FR4 material can exceed 300 MPa longitudinally while paper options like FR1 often top near 100 MPa. Flexural modulus in FR4 reaches around 20 GPa, reducing flex during handling. Peel strength for copper adhesion commonly meets 1.5 N/mm per IPC-4101E. Glass fibers in FR4 prevent microcracks in vias; paper substrates demand careful drilling to avoid fuzzing.

Practical Solutions and Best Practices for Selecting FR Materials

Material choice aligns with design specs like frequency and environment. Use FR1 for prototypes intended to operate under 85 degrees Celsius. Shift to FR4 for multilayer boards and designs that will see temperatures over 100 degrees Celsius.

Factories verify laminates via supplier audits against IPC-4101E. Sample testing includes z-axis expansion per IPC-TM-650 2.4.39 to predict warpage risks.

- Specification Clarity: Note the exact grade in fabrication drawings. Specify /126 for halogen-free FR4 where required.

- Process Matching: Employ FR2 for mechanical punching; use FR4 for laser drilling and high-density interconnects.

- Quality Checks: Inspect laminates for voids post-press. Conduct 288 degrees Celsius solder float for FR3 validation when appropriate.

Incorporate stack-up simulations to evaluate CTE mismatch. Production lines often achieve >98 percent first-pass yields with FR4 in complex builds. Document deviations for traceability.

For cost control, consider hybrid stacks that blend FR3 cores with FR4 outer layers. This balances performance without full FR4 premiums.

Criterion · FR1/FR2 Fit · FR3 Fit · FR4 Fit

Operating Temp · <105°C · 105–130°C · >130°C

Cost per sqm · Lowest · Moderate · Higher

Layer Suitability · 1–2 · 1–2 · 4+

This quick guide helps production engineers decide at a glance. Automated presses and controlled cure profiles optimize FR4 curing at typical pressures used in high-volume lamination.

Related Reading: FR1 vs FR2 vs FR3 vs FR4: How to Choose the Right PCB Material

Insights from the Manufacturing Floor

Factory operations expose material nuances. FR1 absorbs humidity rapidly, often extending bake times to four hours pre-etch. Controlled environments below 50 percent relative humidity mitigate this.

FR2's cotton base reduces chipping in V-scoring but generates more dust, requiring enhanced filtration and vacuum extraction. FR3's epoxy improves solder mask adhesion over phenolics, cutting peel defects in double-sided runs.

Delamination is a common failure mode for FR1 under thermal cycling. IPC-TM-650 method 2.6.7 shows failures after extended cycles between −40 and 125 degrees Celsius in some paper laminates; factories counter with controlled ramp profiles. FR4 high-Tg variants handle lead-free reflow peaks at ~260 degrees Celsius without blistering. Inline ultrasonic inspection detects voids early. Assembly feedback often notes FR3 is adequate for many automotive prototype panels.

Adhering to IPC-A-600M visual acceptability criteria standardizes inspections. Pilot panels confirm manufacturability before ramping to volume production.

Conclusion

FR1, FR2, FR3, and FR4 differ in reinforcement, resin, and capabilities for types pf PCBs. Paper bases in FR1 to FR3 prioritize affordability for basic uses. Fiberglass in FR4 ensures precision in advanced and high-reliability designs. Manufacturing relies on IPC-4101E for qualification and IPC-6012F/IPC-A-600M for performance and acceptability checks. Key distinctions guide material selection to enhance reliability and efficiency. Teams achieve optimal results through tested practices and early specification reviews. Future trends favor more sustainable, halogen-free FR4 variants. Informed choices sustain production excellence.

Q1: What sets FR1 apart from FR2 in PCB materials?

A1: FR1 uses cellulose paper with phenolic resin for economical single-layer PCBs. FR2 employs cotton paper for superior mechanical handling in punching processes. Both maintain relatively low Tg but FR2 resists tearing better. Factories select FR2 for telecom applications where durability matters. IPC-4101E grade /02 confirms FR2 specs and helps prevent routing defects in volume runs.

Q2: How do FR3 and FR4 differ for multilayer PCBs?

A2: FR3 features epoxy on paper for moderate thermal stability in double-sided boards. FR4 integrates glass fabric for low CTE and high strength in complex stacks. FR3 controls costs while FR4 supports high frequencies and via reliability. Manufacturing tests per IPC-6012F validate FR4's performance in multilayer via reliability. Choose based on layer count, thermal profile, and signal requirements to minimize defects.

Q3: Why prefer FR4 over FR1 in high-temperature applications?

A3: FR4's fiberglass reinforcement yields higher Tg and tensile strength, enabling PCBs to withstand higher temperatures and mechanical stress. FR1's paper base limits use to ambient or low-temperature conditions. FR4 minimizes dimensional expansion during reflow and reduces via and solder joint failures. Factories report more stable yields with FR4 in server and high-density production runs.

Q4: What role does IPC-4101E play in FR1 vs FR4 selection?

A4: IPC-4101E specifies laminate grades and slash sheets for consistent properties across FR1 to FR4 materials. Factories use it to qualify suppliers, verify resin and reinforcement combinations, and predict thermal and electrical performance. Adherence to the standard reduces variability in material traits and supports reliable manufacturing across designs.

[Reference 1] IPC-4101E — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2017 (with Amendment 1, 2020).

[Reference 2] IPC-6012F — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2023.

[Reference 3] IPC-A-600M — Acceptability of Printed Boards. IPC, 2025.