Introduction

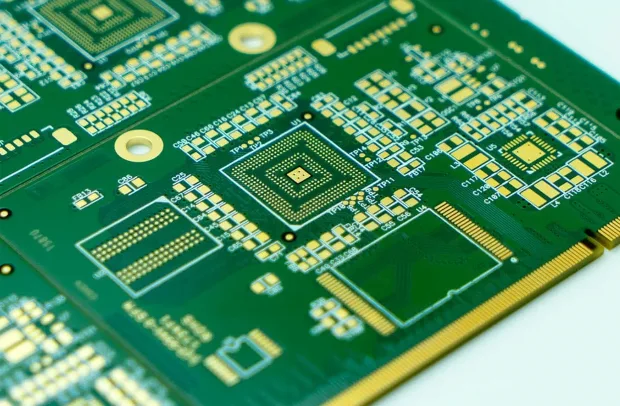

High-Tg PCBs use base materials with glass transition temperatures of 170 °C or higher. These laminates maintain dimensional stability and mechanical integrity during multiple lead-free reflow cycles, high operating temperatures, and long-term thermal aging in aerospace, automotive, and industrial control systems. Selecting and processing high-Tg materials correctly determines whether the final assembly survives 3000 h at 150 °C or fails within months.

What Defines a High-Tg Laminate

Glass transition temperature (Tg) marks the point where the resin changes from glassy to rubbery state. Standard PCB FR4 material ranges 130–140 °C. High-Tg materials start at 170 °C and reach 200 °C+ in extreme cases.

| Category | Typical Tg (DSC midpoint) | Common Resin System | Td (decomposition) | CTEz below Tg |

|---|---|---|---|---|

| Mid-Tg FR-4 | 130–150 °C | Dicy-cured FR-4 | 310–340 °C | 70–90 ppm/°C |

| High-Tg | 170–180 °C | Phenolic-cured FR-4 | 340–380 °C | 50–70 ppm/°C |

| Very High-Tg | 185–200 °C | Multifunctional + PPE blends | 390–420 °C | 40–55 ppm/°C |

| Ultra High-Tg | >200 °C | Polyimide, cyanate ester | >420 °C | <40 ppm/°C |

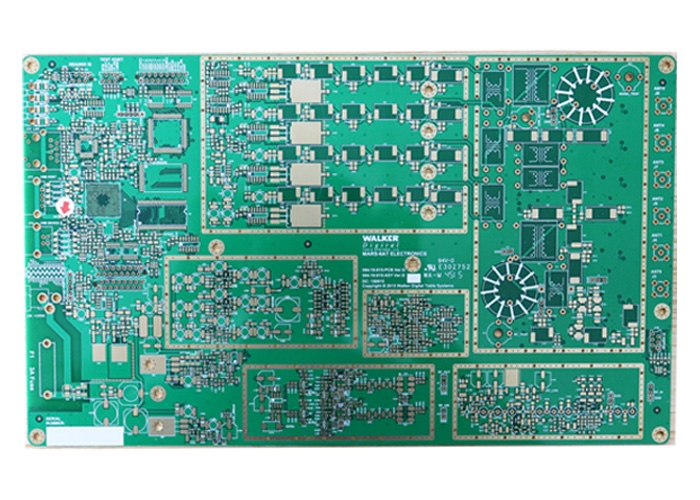

Why Aerospace Requires High-Tg Materials

Avionics boards undergo six or more 260–270 °C reflow cycles plus conduction or vapor-phase soldering. DO-160G Section 5 temperature-altitude tests reach +90 °C continuous. Laminates below 170 °C Tg risk delamination, conductive anodic filament (CAF), and pad cratering.

IPC-6012E Class 3/A aerospace qualification mandates:

- Minimum Tg 170 °C (IPC-TM-650 2.4.24)

- Td ≥340 °C (5 % weight loss, IPC-TM-650 2.4.24.6)

- T260 ≥30 min, T288 ≥15 min with no delamination

- CTEz ≤70 ppm/°C below Tg

Automotive AEC-Q100/Q200 Requirements

Under-hood and powertrain electronics see 150 °C continuous and 175 °C peaks. AEC-Q100 Grade 0 demands 3000 h at 150 °C without measurably increasing resistance in plated through-holes.

Typical automotive high-Tg choices:

- 175 °C phenolic-cured FR-4 (most common)

- 185 °C multifunctional for radar modules

- 200 °C polyimide for transmission control units near exhaust

Industrial Control and Downhole Applications

Servo drives, frequency inverters, and geothermal logging tools operate continuously at 125–175 °C. High-Tg material prevents z-axis expansion from fracturing microvias during 5000+ temperature cycles.

Material Selection Matrix for High-Tg PCBs

| Application | Operating Temp | Reflow Cycles | Recommended Minimum Tg | Typical Filler | IPC-4101E Slash Sheet |

|---|---|---|---|---|---|

| Commercial/Consumer | <100 °C | ≤3 | 140–150 °C | None | /21, /24 |

| Industrial control | 125 °C | ≤6 | 170 °C | Yes | /126, /129 |

| Automotive under-hood | 150 °C | ≤8 | 175–180 °C | Yes | /130, /131 |

| Aerospace avionics | 90–110 °C | ≥6 | 180 °C | Low CTE | /121, /124 |

| Oil & gas downhole | 175–200 °C | Conformal | ≥200 °C (polyimide) | Ceramic | /101 (polyimide) |

Critical Manufacturing Adjustments for High-Tg Materials

Bake Cycles

High-Tg resins absorb less moisture than standard FR-4 but require longer pre-bake (8–12 h at 120–130 °C) to reach <0.08 % moisture before lamination.

Lamination Pressure and Temperature

Phenolic-cured 175–180 °C Tg materials need higher pressure (400–550 psi) and longer dwell at 185–195 °C to achieve full cross-linking.

Desmear and Hole-Wall Roughening

Higher Tg correlates with harder resin. Standard permanganate desmear often proves insufficient. Plasma + permanganate or extended chemical cycles become mandatory to achieve ≥20 µm etch-back for reliability.

Drilling Parameters

Lower CTE and higher hardness demand reduced chipload (≤0.025 mm/rev) and lower spindle speeds (≤80 krpm) to prevent smear and nail-heading on inner-layer copper.

Thermal Management Benefits of High-Tg Materials

Although Tg itself does not conduct heat, high-Tg laminates typically incorporate low-CTEz fillers that reduce z-axis expansion by 30–50 %. Lower expansion preserves via barrel integrity and reduces stress on solder joints at high temperature.

Reliability Testing Requirements

| Test | Standard | High-Tg Pass Criteria (typical) |

|---|---|---|

| T260 with 50 µm Cu | IPC-TM-650 2.4.24.1 | ≥60 minutes, no delamination |

| T288 with 50 µm Cu | IPC-TM-650 2.4.24.1 | ≥20 minutes, no measles or blistering |

| IST (Interconnect Stress) | IPC-TM-650 2.6.26 | ≥500 cycles to first failure (Class 3) |

| Thermal shock (air-air) | IPC-TM-650 2.6.7.2 | 1000 cycles −55 °C to +150 °C, no crack |

| HATS 150 °C | OEM-specific | 3000 h, ΔR <5 % on via chains |

Suggested Reading: Boosting PCB Reliability: Mastering High-Tg PCB Manufacturing

Conclusion

High-Tg PCBs have become mandatory whenever continuous operating temperature exceeds 110 °C or multiple lead-free reflow cycles are required. Selecting the correct Tg level (170 °C for most industrial, 180 °C+ for aerospace and automotive Grade 0) and adjusting fabrication processes accordingly ensures long-term reliability under the harshest thermal environments.

FAQs

Q1: Is 170 °C Tg sufficient for automotive under-hood applications?

A1: Yes, most AEC-Q100 Grade 1 applications (150 °C max) successfully use 170–175 °C phenolic-cured high-Tg FR-4 when T288 exceeds 15 minutes and proper baking is performed.

Q2: When should designers move from 175 °C to 200 °C polyimide materials?

A2: Move to polyimide only for continuous operation above 175 °C (downhole tools, engine-mounted electronics) or when T260/T288 requirements exceed capabilities of filled FR-4 systems.

Q3: How much does high-Tg material reduce via failures in thermal cycling?

A3: Reducing CTEz from 80 ppm/°C (mid-Tg) to 50 ppm/°C (180 °C Tg) typically extends plated-through-hole life from <1000 cycles to >3000 cycles between −40 °C and 150 °C.

Q4: Are all high-Tg materials harder to process than standard FR-4?

A4: Yes, they require longer bake times, higher lamination pressure, extended desmear cycles, and adjusted drilling parameters, but modern 175–180 °C systems remain fully compatible with standard lead-free assembly processes.

References

IPC-4101E — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2017.

IPC-TM-650 2.4.24 — Glass Transition Temperature and Z-Axis Thermal Expansion. IPC, current version.

IPC-TM-650 2.4.24.1 — Time to Delamination (T260, T288). IPC, current version.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-TM-650 2.6.26 — Interconnect Stress Testing (IST). IPC, current version.