What Distinguishes Aluminum PCBs and Why Are They Unique for Soldering?

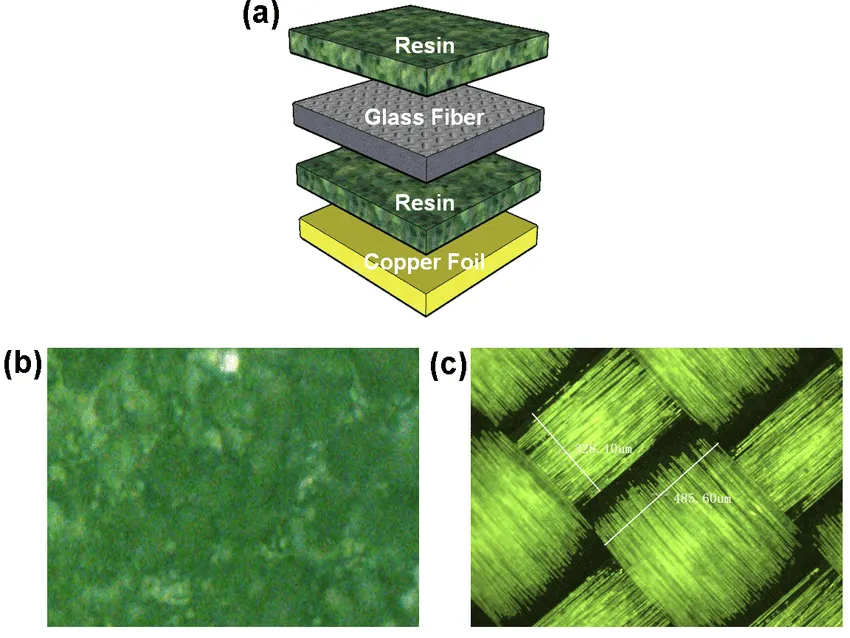

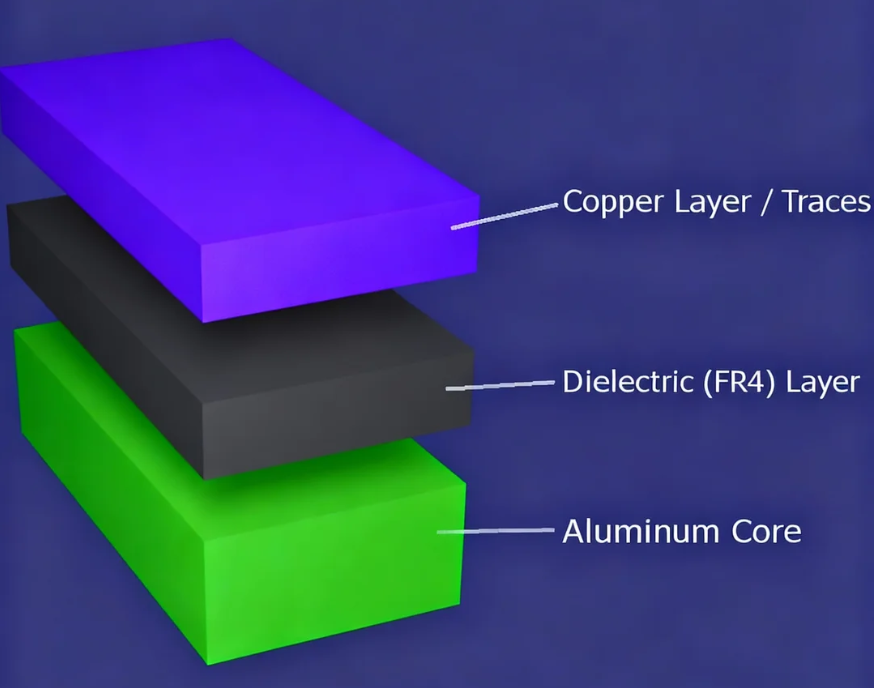

Aluminum PCBs, often referred to as metal core PCBs, fundamentally differ from conventional boards by incorporating an aluminum base layer instead of the more common FR4 material. This metallic core is engineered to provide exceptional thermal conductivity, typically ranging from 1 to 2 W/mK, a significant improvement over FR4’s mere 0.3 W/mK. This superior heat dissipation capability makes aluminum PCBs an ideal choice for applications that generate substantial heat, such as high-power LED lighting systems and various power electronics.

However, this very advantage presents a unique challenge during the soldering process. Aluminum’s high thermal conductivity means that heat applied to a solder joint rapidly disperses across the board, making it difficult to maintain the localized temperature necessary for proper solder joint formation. Without careful management, this rapid heat transfer can lead to "cold solder joints," which are electrically unreliable and mechanically weak. A deep understanding of these thermal characteristics is therefore crucial for effectively soldering aluminum PCB components, ensuring robust and dependable connections.

What Are the Primary Challenges When Soldering Aluminum Circuit Boards?

Before delving into specific soldering methods, it's crucial to acknowledge how the very features designed for thermal management in high-power electronics create unique difficulties for aluminum PCBs:

● Exceptional Thermal Conductivity: The inherent ability of aluminum to conduct heat far more rapidly than standard PCB substrates necessitates either significantly higher soldering temperatures or specialized equipment capable of sustaining localized heat at the joint.

● Risk of Thermal Damage: Applying excessive or uncontrolled heat can pose a threat to sensitive electronic components or compromise the integrity of the dielectric layer positioned between the aluminum core and the copper circuitry.

● Solder Material Compatibility: Standard solder pastes and fluxes may not be optimally suited for aluminum PCBs. The distinct thermal and surface properties of aluminum demand specific formulations to ensure proper wetting, adhesion, and long-term reliability of the solder joints.

Addressing these challenges is key to successfully soldering aluminum PCBs, whether utilizing automated reflow processes or precise hand-soldering techniques.

How to Choose the Optimal Solder Paste for Aluminum PCB Assembly

Selecting the correct solder paste is a critical step in achieving durable and dependable solder joints on aluminum PCBs. Given aluminum's unique thermal properties, not all standard solder pastes will perform effectively. Here are essential considerations for making the right choice:

● Lead-Free Alloy Composition: Prioritize lead-free solder pastes, typically formulated with SAC (Tin-Silver-Copper) alloys like SAC305. These alloys offer a suitable melting point, generally between 217°C and 221°C, and exhibit excellent wetting characteristics on aluminum PCB surfaces.

● Flux Type and Compatibility: Employ a flux system—either "no-clean" or water-soluble—that is specifically engineered for materials with high thermal conductivity. The flux's role is to effectively remove oxides from the metal surfaces, thereby promoting superior solder adhesion and flow during the heating process.

● Solder Particle Size: For accurate and consistent paste deposition, especially with miniaturized components or fine-pitch pads, opt for a solder paste with a finer particle size, such as Type 4 or Type 5.

Using the appropriate solder paste minimizes common issues like voiding (empty spaces within the solder joint) or poor wetting (solder not fully spreading), which frequently occur when soldering aluminum PCB components. Always consult the solder paste manufacturer’s specifications and recommendations for compatibility with metal core boards to prevent potential assembly failures.

Mastering Aluminum PCB Soldering Temperatures: Achieving the Ideal Thermal Profile

One of the most critical aspects of successfully soldering aluminum PCBs is precise temperature management. Due to aluminum’s high thermal conductivity, heat rapidly dissipates away from the solder joint, often necessitating higher overall temperatures or extended preheat phases compared to standard FR4 boards. Here are key guidelines for establishing an effective aluminum PCB soldering temperature profile:

● Preheat Phase: Initiate the process with a preheat temperature ranging from 150°C to 180°C, sustained for approximately 60-90 seconds. This stage is crucial for gradually elevating the board's temperature, minimizing thermal shock to sensitive components, and ensuring uniform heat distribution across the entire PCB.

● Soak Phase: Follow with a soak stage, maintaining the temperature between 180°C and 200°C for 30-60 seconds. During this period, the flux becomes fully activated, and the solder paste prepares for its molten state.

● Reflow Peak Stage: Elevate the temperature to the peak reflow range of 235°C to 250°C, held for 20-40 seconds. This temperature window is optimized for most lead-free solder pastes, ensuring complete melting and proper wetting of the solder onto the aluminum surfaces.

● Controlled Cooling Phase: Conclude by allowing the board to cool down gradually at a rate of 2-4°C per second. This controlled cooling prevents thermal stress, which could lead to cracking within the newly formed solder joints.

It’s important to note that these temperature guidelines are general recommendations. Always refer to the specific thermal profile provided by your chosen solder paste manufacturer and adjust based on the unique size, thickness, and component density of your aluminum PCB. Employing a reflow oven with advanced, precise temperature controls or a specialized hot plate designed for metal core PCBs can significantly aid in maintaining these critical temperatures consistently.

For more knowledege about aluminum PCB soldering, see our comprehensive guide: Aluminum PCBs: The Comprehensive Guide to Metal Core Circuit Boards

Step-by-Step Reflow Soldering for Aluminum PCBs

Reflow soldering stands as the preferred and most efficient method for assembling aluminum PCBs in high-volume production, offering superior consistency and quality. This process involves precise application of solder paste, automated component placement, and controlled heating of the entire board to form robust solder joints. Here’s a detailed breakdown of the reflow soldering aluminum PCB process:

1. PCB Preparation: Begin by thoroughly cleaning the aluminum PCB surface to eliminate any contaminants such as dirt, grease, or oxides. Isopropyl alcohol and a lint-free cloth are recommended for optimal results.

2. Solder Paste Application: Utilize a high-precision stencil to apply solder paste uniformly onto all designated component pads. Ensure the paste is confined precisely to the pad areas to prevent excess solder and potential bridging.

3. Component Placement: Carefully position all surface-mount components onto the freshly applied solder paste. This is typically done with a pick-and-place machine for accuracy in mass production, or manually with tweezers for smaller runs. Verify correct component alignment.

4. Preheating: Place the prepared quick turn PCB into a reflow oven or onto a controlled hot plate. Adhere to the preheat temperature guidelines (150°C to 180°C for 60-90 seconds) to ensure the board warms up evenly and gradually.

5. Reflow Stage: Increase the temperature to the peak reflow range (235°C to 250°C for 20-40 seconds), following the specific requirements of your chosen solder paste. Continuously monitor the process to confirm that the solder melts completely and forms proper, reliable joints.

6. Cool Down: Allow the board to cool down slowly, either within the oven's cooling zone or on the hot plate, maintaining a gradual cooling rate (2-4°C/second). Avoid any rapid cooling, as this can induce thermal stress and weaken the newly formed joints.

7. Post-Soldering Inspection: Once cooled, meticulously inspect all solder joints for any defects, such as cold solder connections, voids, insufficient wetting, or bridging. High-magnification tools or Automated Optical Inspection (AOI) systems are invaluable for precise detection.

Due to the inherent high heat dissipation of aluminum boards, achieving successful reflow soldering aluminum PCB results demands rigorous attention to temperature control throughout the process. Investing in a reflow oven that offers customizable thermal profiles specifically optimized for metal core PCBs can significantly enhance quality and yield, especially for large-batch manufacturing.

Related Reading: Step by Step: Reflowing SMT Components on Aluminum PCBs for Beginners

Practical Tips for Hand Soldering Aluminum PCBs in Small Projects

For prototyping or small-batch assembly, hand soldering aluminum PCB components is often more feasible than setting up a full reflow line. However, the rapid heat dissipation of aluminum presents unique challenges. Here are practical tips to ensure successful hand soldering:

● Utilize a High-Power Soldering Iron: Opt for a soldering iron with substantial wattage, ideally 60-80 watts or more. This higher power output helps compensate for the quick heat loss into the aluminum core. An iron with precise temperature control is essential.

● Set an Elevated Tip Temperature: Adjust your soldering iron's temperature to a range of 300°C to 350°C for lead-free solder. This higher setting ensures the iron tip can maintain sufficient heat at the joint despite the aluminum's thermal conductivity.

● Preheat the PCB: Before beginning to solder, preheat the entire PCB using a hot plate or a heat gun to approximately 100°C to 150°C. This reduces the thermal gradient between the board and the iron, promoting better solder flow and preventing thermal shock.

● Work Swiftly and Precisely: Apply solder and position components with speed and efficiency to minimize localized heat loss. Use a fine-tipped iron for precision, and avoid prolonged contact with pads to prevent overheating sensitive components or the dielectric layer.

● Apply Flux Generously: Before soldering each joint, apply a suitable amount of flux directly to the pads. This improves solder wetting, helps remove oxidation, and ensures a cleaner, stronger connection on the aluminum surface. Ensure the flux is compatible with high-temperature soldering.

● Inspect and Rework Carefully: After soldering, thoroughly inspect each joint for quality—it should appear shiny and well-formed. If a joint appears dull, gritty, or uneven (indicating a cold joint or poor wetting), briefly reheat it while adding a small amount of fresh flux and solder to achieve a proper connection.

Hand soldering aluminum PCB components requires practice and patience, especially for those new to this material. Always prioritize safety by working in a well-ventilated area and wearing appropriate protective gear to prevent burns or exposure to fumes.

Common Pitfalls and Essential Tools for Soldering Aluminum PCBs

Mistakes to Avoid for Reliable Joints

Even experienced technicians can make mistakes. When soldering aluminum PCBs, be vigilant about these common pitfalls to ensure high-quality, long-lasting connections:

● Insufficient Heat: Failing to supply and maintain adequate heat at the joint is a primary cause of cold solder joints, leading to poor electrical continuity and weak mechanical bonds.

● Overheating: Applying too much heat for too long can severely damage sensitive electronic components or degrade the critical dielectric layer of the PCB. Continuous temperature monitoring is essential.

● Incompatible Solder Paste: Using a solder paste not specifically formulated for high thermal conductivity materials can result in poor wetting, excessive voiding, or unreliable adhesion.

● Skipping Preheat: Neglecting the preheat stage can induce thermal shock, potentially causing component cracking or weakening the integrity of solder joints.

● Inadequate Cleaning: Any residual flux or contaminants left on the board after soldering can lead to corrosion over time, compromising long-term reliability. Always clean the PCB thoroughly with appropriate solvents.

Essential Tools for Quality Soldering

Equipping yourself with the right tools significantly enhances the quality and efficiency of your aluminum PCB soldering work:

● Reflow Oven or Controlled Hot Plate: Indispensable for achieving consistent and controlled heating profiles during reflow soldering, particularly for larger boards or production runs.

● High-Power Soldering Iron (60-80+ Watts): Crucial for hand soldering, allowing the tip to maintain sufficient heat despite the aluminum’s rapid thermal dissipation. Look for models with precise temperature control.

● Specialized Solder Paste and Compatible Flux: Always choose lead-free solder paste and flux explicitly designed for high thermal conductivity substrates.

● Solder Stencil: Essential for accurate and uniform application of solder paste in reflow processes.

● Precision Tweezers and Magnifying Glass/Microscope: For delicate component placement and detailed inspection of solder joints.

● Heat Gun: Useful for localized preheating, rework tasks, or carefully removing components.

● PCB Cleaning Supplies: Isopropyl alcohol, specialized flux removers, and lint-free brushes are vital for pre- and post-soldering cleanliness.

Investing in quality tools tailored for aluminum PCBs will streamline your work, improve efficiency, and, most importantly, significantly enhance the reliability of your solder joints.

Final Thoughts on Successfully Soldering Aluminum PCBs

Soldering aluminum PCBs, while presenting challenges due to their inherent high thermal conductivity, is entirely achievable with the correct techniques and equipment. Whether you are employing reflow soldering for mass production or hand soldering for intricate prototypes, a comprehensive understanding of aluminum PCB soldering temperatures, the strategic selection of appropriate solder paste for aluminum PCB materials, and strict adherence to established best practices are all fundamental pillars of success.

By diligently mastering these specialized soldering techniques for aluminum PCB components, you will be well-equipped to create robust, highly reliable connections that can withstand the rigorous demands of high-power applications. Continuous practice, meticulous attention to temperature management, and unwavering commitment to cleanliness and precision in every step of your work will empower you to confidently tackle any aluminum PCB project and achieve consistently superior results.