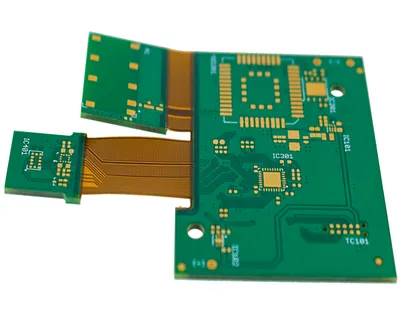

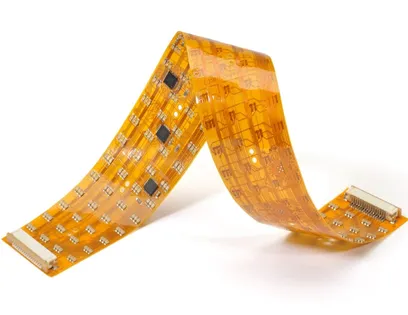

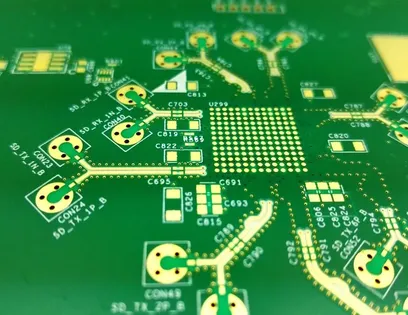

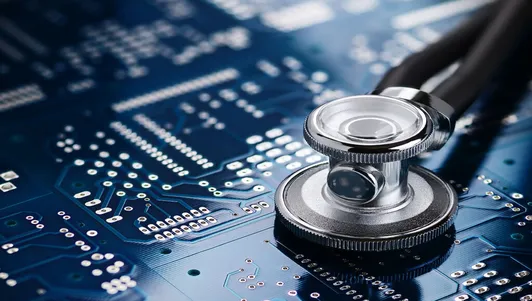

Demands for PCBs in Medical Devices

-

Demands for PCBs in medical devices are driven by the need for high reliability, safety, and precision. Medical PCBs must meet strict regulatory standards, including ISO and IPC requirements, to ensure consistent performance in critical applications. They often require biocompatible materials, compact designs, and high-density layouts to support advanced functionality. Additionally, medical devices demand long-term stability, low failure rates, and traceable manufacturing processes to guarantee patient safety and regulatory compliance.