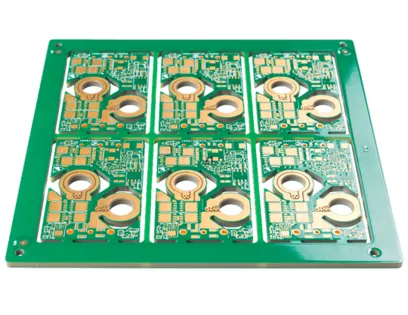

Demands for PCBs in New Energy

-

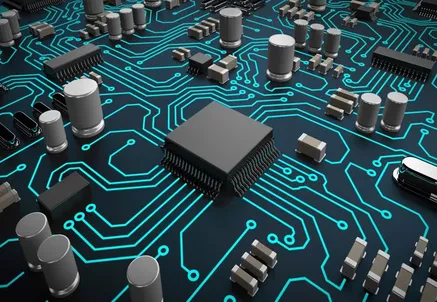

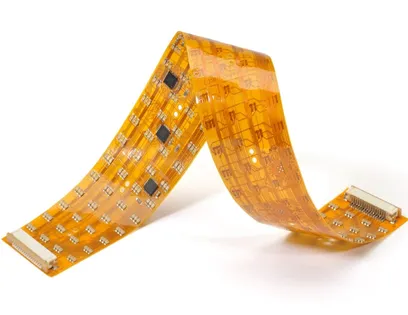

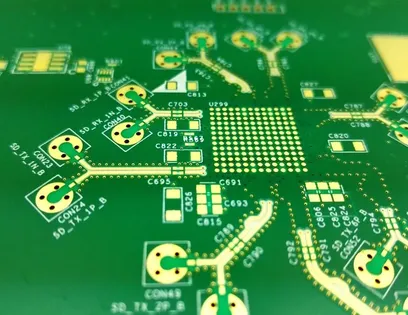

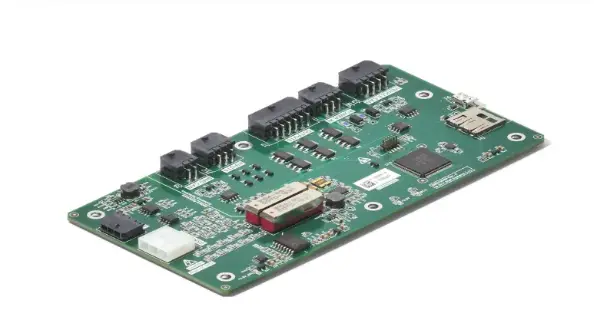

The rapid evolution of renewable energy technologies necessitates PCBs that handle high voltages and currents with exceptional efficiency. In the New Energy sector, reliability is non-negotiable. AIVON provides heavy-copper and high-Tg PCB solutions tailored for solar inverters, wind turbines, and energy storage systems. Our boards are rigorously tested to withstand environmental stress and manage high power loads, ensuring stable conversion and transmission. We empower your green innovations with robust circuitry designed to support the sustainable infrastructure of tomorrow.