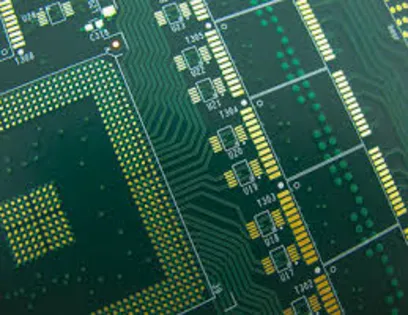

Demands for PCBs in Power Supply

-

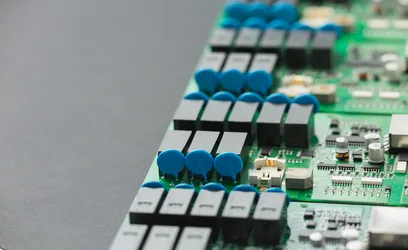

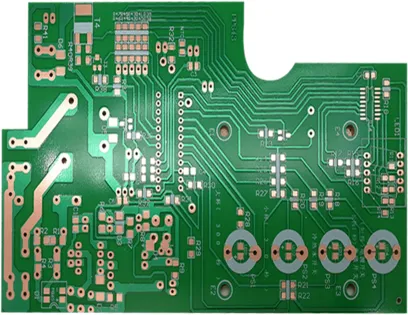

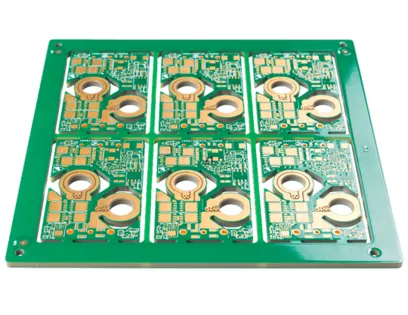

Power supply units (PSUs) form the heartbeat of electronic devices, requiring PCBs that balance high power density with compact design. The primary challenge lies in effective thermal management and safety compliance under heavy loads. AIVON manufactures specialized power PCBs featuring heavy copper traces and high-thermal-conductivity substrates to prevent overheating and ensure stable AC/DC conversion. From consumer adapters to industrial rectifiers, our solutions offer the electrical robustness and safety certifications needed to deliver consistent power in increasingly smaller footprints.