Demands for PCBs in Automotive Electronics

-

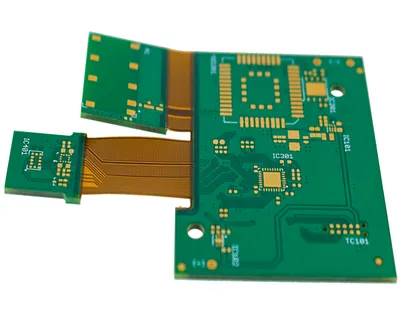

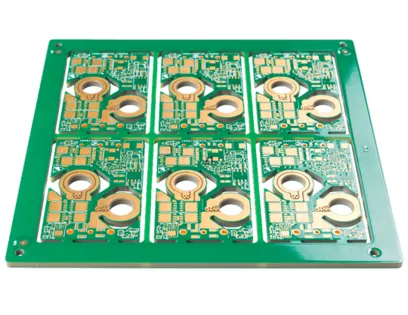

Demands for PCBs in automotive electronics focus on high reliability, safety, and durability under harsh operating conditions. Automotive PCBs must withstand extreme temperatures, vibration, humidity, and electrical noise while maintaining stable performance. They support critical systems such as engine control units, ADAS, infotainment, and electric vehicle power modules. In addition, automotive PCBs require long service life, precise signal integrity, and compliance with strict standards such as IATF 16949 and ISO 26262 to ensure vehicle safety and functional reliability.

.webp)

%20Battery%20Management.webp)