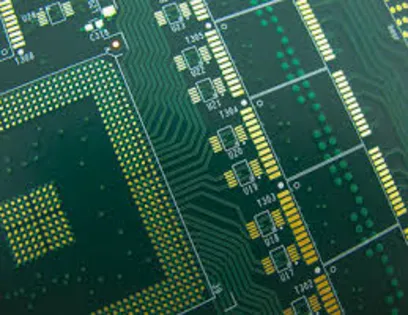

Demands for PCBs in Consumer Electronics

-

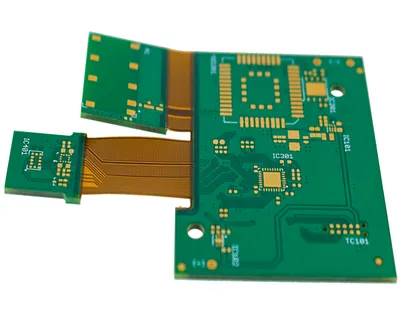

Demands for PCBs in consumer electronics are driven by rapid product innovation, compact form factors, and competitive pricing. Modern devices require high-density interconnects, multilayer and HDI designs to support powerful processors, high-speed data transmission, and multiple functions in limited space. PCBs must provide excellent signal integrity, thermal management, and mechanical reliability for long-term use. In addition, manufacturers demand cost-efficient, high-yield production processes, fast turnaround times, and compliance with international quality and environmental standards to meet global market expectations.