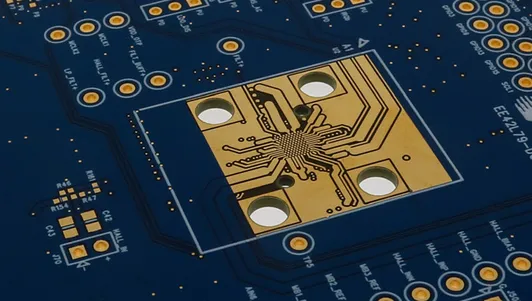

Demands for PCBs in Military and Aerospace

-

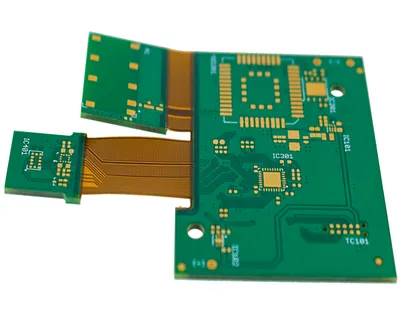

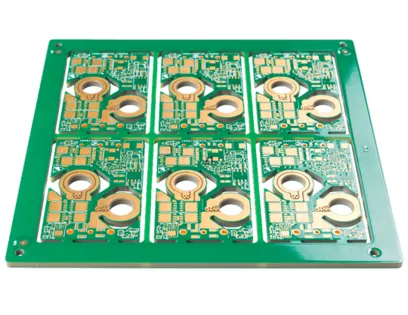

Demands for PCBs in military and aerospace applications are driven by the need for extreme reliability, durability, and precision under harsh conditions. These PCBs must operate flawlessly under high vibration, wide temperature ranges, and exposure to radiation. They support critical systems such as avionics, radar, satellites, and defense electronics, requiring multilayer, high-density, and high-frequency designs. Materials must withstand thermal stress and mechanical fatigue, while manufacturing processes must ensure minimal defects. Compliance with stringent standards like MIL-PRF-31032 and IPC-6012 Class 3 is essential to guarantee long-term performance, safety, and mission-critical reliability in aerospace and military operations.