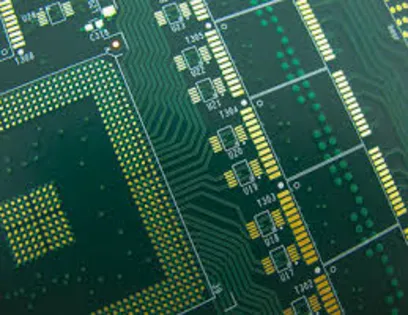

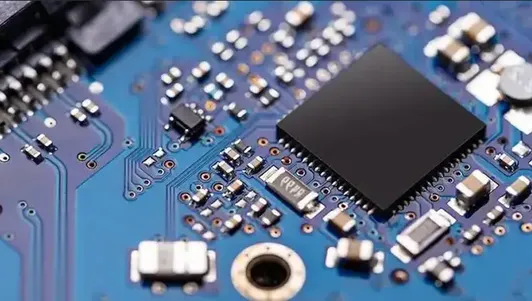

Demands for PCBs in Telecommunication

-

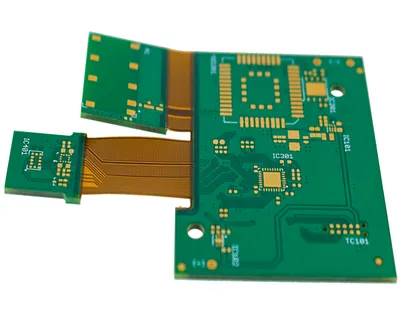

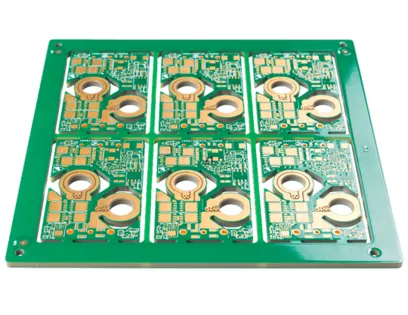

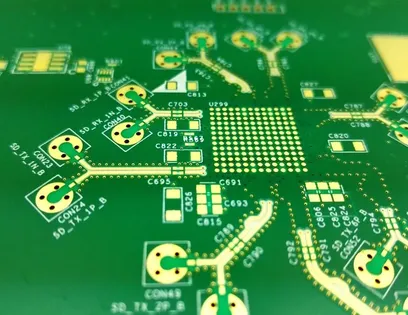

Demands for PCBs in telecommunication are driven by the need for high-speed, reliable signal transmission and network stability. Telecommunication PCBs must support high-frequency performance, low signal loss, and precise impedance control to ensure efficient operation in base stations, routers, switches, satellite systems, and 5G infrastructure. Compact, multilayer, and HDI designs are often required to handle complex circuits in limited space. Additionally, these PCBs must offer thermal stability, long-term reliability, and compliance with international quality standards to meet the rigorous demands of modern communication networks and evolving global connectivity requirements.