Introduction

Person A: Battery warranty is 5 years, replace it after warranty expires.

Person B: Mainly perform battery internal resistance testing every six months, and replace any problematic units promptly.

Person C: Replace at five years, but in many sites batteries fail earlier due to room environment. To be economical, all factors must be considered.

How often should a battery be replaced? How should maintenance be performed to extend battery life and optimize economic return?

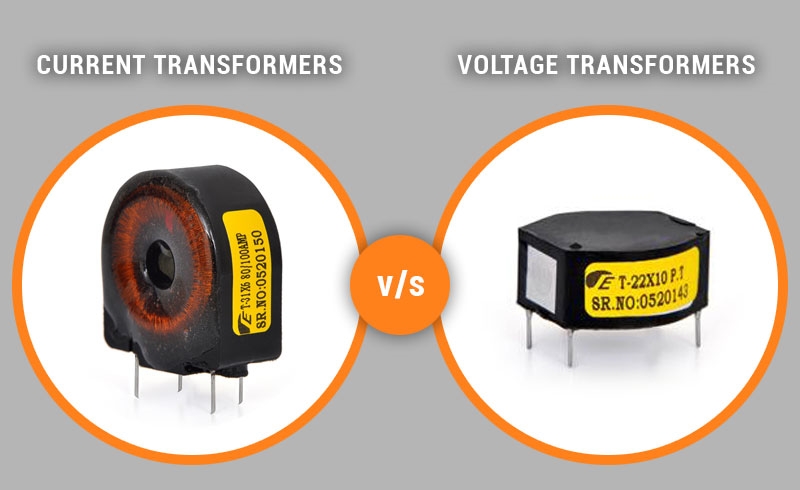

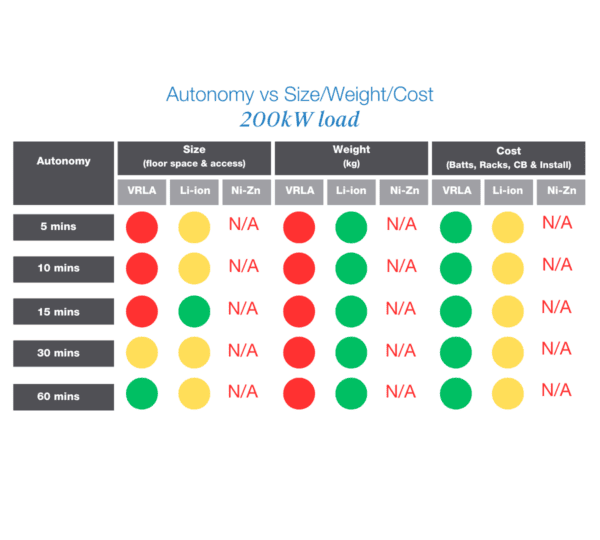

A review of the literature found that batteries are one of the most important components of a UPS system and serve as the final barrier for the power supply. Currently, batteries used in data center UPS systems are mainly valve-regulated lead-acid batteries (VRLA), but with advances in battery technology, lithium batteries and fuel cells are becoming alternative options.

1. Selection and Design Principles for Data Center UPS Batteries

The selection and design of data center UPS batteries must fully consider modern data center characteristics and development trends, and should follow these principles:

- Excellent short-duration constant-power output

Outstanding short-duration (typically ≤ 30 min) constant-power output allows smaller battery capacity for the same backup time requirement, reducing battery cost; or, with the same capacity, it increases total UPS backup time. - High energy density

Select appropriate battery type and capacity and design a合理 assembly structure to optimize room space usage and increase overall battery energy density, reducing room area and cost. - High stability

Batteries should have a low failure rate during their effective life, avoiding maintenance or replacement caused by individual cell failure, which is important for long-term system safety and stability. - Fire retardancy

UPS battery enclosures should use plastics meeting V0 flammability standards. Exposed metal parts such as battery terminals, connectors, and output busbar terminals should be insulated, and battery racks must be grounded. - Consistency

Individual cells in a data center UPS battery string should meet consistency requirements for capacity, open-circuit voltage, float voltage, and other indicators per relevant standards. - Seismic resistance

Battery rack design should meet seismic intensity level 8 requirements. Flexible connections between batteries are recommended. - Ease of installation and expansion

Modular battery design and provision of dedicated installation tools can reduce overall installation cost. Battery placement and rack design should reserve space for future expansion. - Ease of maintenance and replacement

Clear access and maintenance aisles should accommodate routine maintenance and battery replacement. - Long service life

UPS batteries should have a reasonable expected service life; too short a life increases system instability and cost.

2. Key Maintenance Points

- Place insulating mats in battery maintenance aisles.

- Do not mix batteries from different manufacturers, different capacities, or different models in the same system.

- VRLA batteries do not require initial charging before use but should receive a supplementary charge. Supplementary charging voltage must follow the product technical manual.

- VRLA battery equalization charging: Generally perform equalizing charge when one of the following conditions occurs (follow product technical manual for special requirements). Charge current must not exceed 0.2C10.

- 1) More than two cells have float voltage below 2.18 V per cell.

- 2) Batteries have been idle for longer than 3 months.

- 3) Continuous float operation has reached 6 months.

- 4) Depth of discharge exceeds 20% of rated capacity.

- 5) For high-voltage DC, consider server input overvoltage protection during equalization (e.g., 282 V).

- Recharge amount should generally be at least 1.2 times the discharged amount. If charge current does not decline for 3 continuous hours, charging is considered complete.

- Set float voltage per product manual and apply temperature compensation. Typical float voltage is 2.23 - 2.25 V (25C, 2 V cell). For a given ambient temperature, use:

U = U0(25C) + (25 - t) * 0.003 (t = ambient temperature)

- During float charging, the maximum cell terminal voltage difference across the string should ideally not exceed 90 mV (2 V cells), 240 mV (6 V), or 480 mV (12 V). Internal resistance deviation should not exceed 15%.

- Perform regular capacity testing and discharge tests:

- 1) Perform a verification discharge test annually, discharging 30% - 40% of rated capacity.

- 2) A full capacity test is recommended every 3 years.

- 3) During discharge tests record individual cell voltage and discharge current at regular intervals.

Summary and Replacement Considerations

- There is no universal regulation specifying how often batteries in a data center must be replaced.

- Organizations should determine replacement timing based on their operational needs.

- Replacement timing is closely related to battery materials, warranty period, number of charge-discharge cycles, changes in internal resistance, and environmental factors in the battery room such as temperature, humidity, and cleanliness; these factors should be evaluated comprehensively.

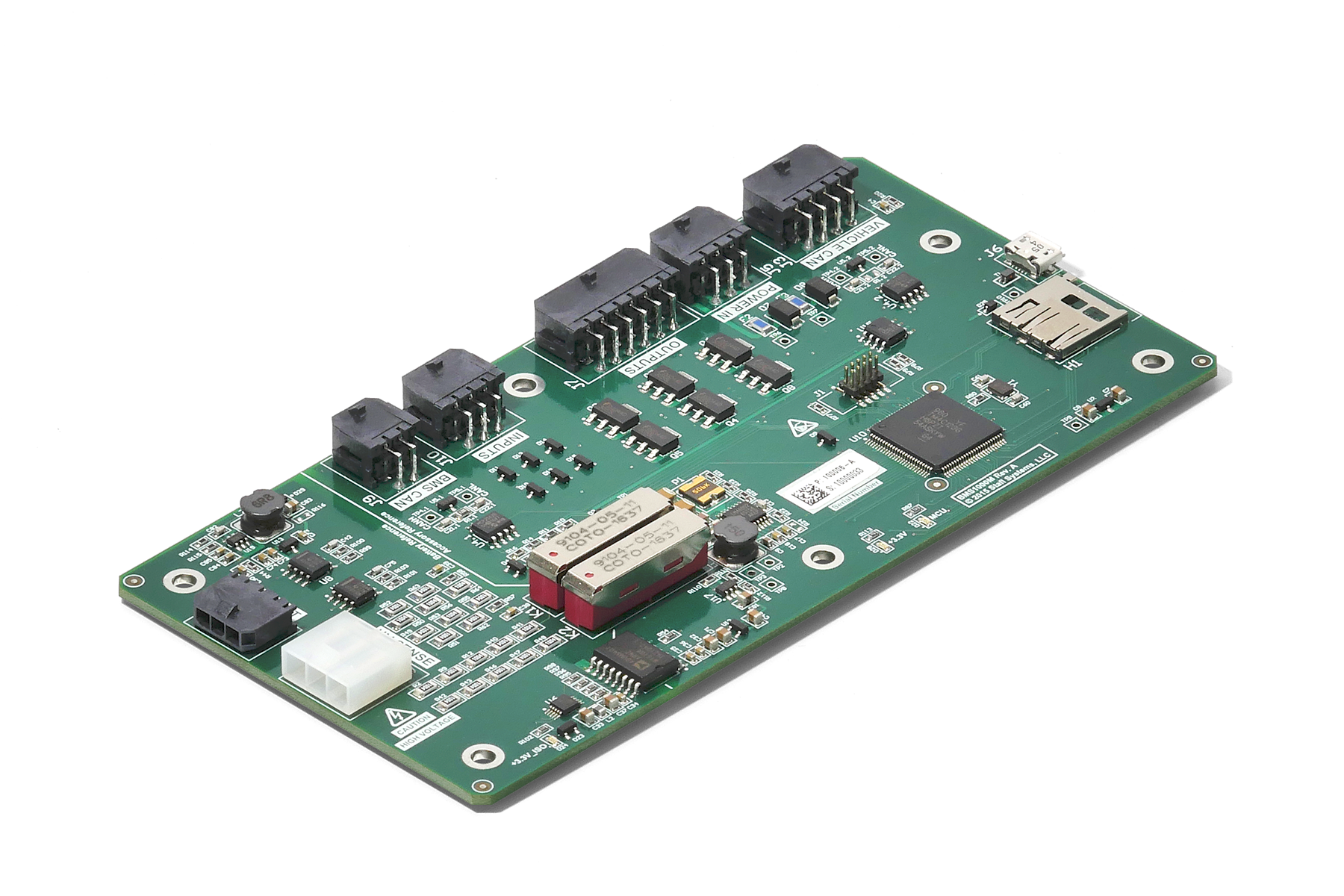

Case Study: UPS Battery Replacement — Preparation and Installation

Replacing UPS batteries can be simple in concept but complex in execution for an operational data center because it affects safe operation. From planning to material handling and on-site work, many steps must be done correctly. The following describes preparation and installation steps from a recent project.

Preconditions

- Approval from higher management.

- Approved emergency procedures.

- Notification to potentially affected customers.

- Notification to the central control center.

- Spare batteries inspected and meeting replacement criteria.

- Labeling plan for new and old batteries established.

Safety Measures

- Provide pre-job safety training for installation personnel.

- Wear appropriate personal protective equipment.

- Assign a dedicated safety officer.

- Prepare measurement instruments and tools, ensuring they are within calibration and validity period.

Preparation

- Assign installation personnel.

- Retrieve the battery batch and spare cables from the warehouse, transport to the data hall, and remove packaging.

- Verify battery parameters and inspect for physical damage; check terminals for oxidation.

- Number batteries and apply sequential machine-printed labels.

- Measure internal resistance and battery voltage with an internal resistance tester; record measurements by label number.

- If the replacement requires switching to generator power, coordinate with the generator team to prevent unexpected mains outages.

Installation Process

- Installation personnel bring installation and test tools (socket set, adjustable wrench, screwdrivers, hydraulic crimper, multimeter, etc.) to the site.

- Verify insulation condition of tool handles.

- Connect the generator output to the backup power industrial connector and start the generator, allowing it to run.

- Open the battery cabinet and photograph for records; locate the UPS output cable and confirm polarity.

- After confirming stable generator output and normal voltage at the switch input, switch input to generator side. Verify UPS is running normally and open the battery cabinet circuit breaker.

- Remove old batteries from top to bottom on the rack. After removing each terminal screw, wrap the disconnected connector with electrical tape for insulation. This step is critical to prevent short circuits between positive and negative terminals.

- Place removed batteries aside and begin installing new batteries.

- Install batteries in sequence from battery 1, starting at the lowest rack position. Maintain the same orientation as before. Tighten terminal screws securely, keep connection cables neat and uniformly bent, leave appropriate spacing between batteries, and strictly avoid short circuits during connections.

- After installation, confirm correct polarity and measure total voltage to verify correct installation and connections.

- Calculate required charging voltage from battery parameters and measure UPS output charging voltage. If charging voltage meets battery requirements, close the battery cabinet circuit breaker and verify the UPS charging menu indicates batteries are charging.

- Reinstall the battery cabinet cover, switch UPS input back to mains, confirm input and output voltages are normal, stop the generator, remove the temporary connection, collect tools, load old batteries for transport, and clean the site.