What Role Do Stencils Play in SMT Assembly?

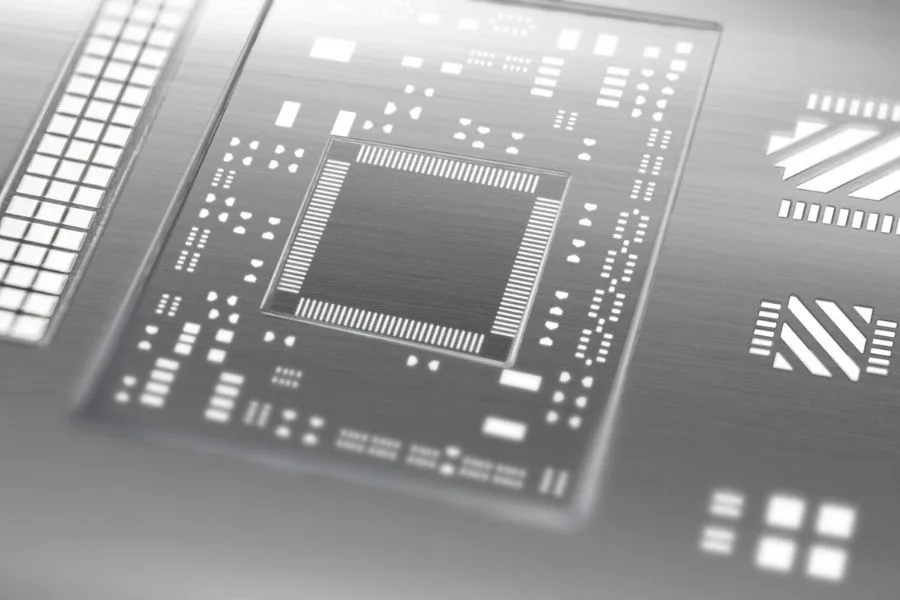

Stencils are fundamental to the surface mount technology (SMT) assembly process, which involves precisely placing electronic components onto printed circuit boards (PCBs). These thin sheets, typically crafted from stainless steel, feature openings that precisely mirror the PCB’s layout. During assembly, solder paste is applied through these apertures, creating the necessary connection points for components.

The precision of this solder paste application directly influences the quality of the final product. Inaccurate paste volume, whether too much or too little, can result in defects such as solder bridging or inadequate joint formation. Therefore, the selection of the appropriate stencil—be it framed or frameless—is a critical decision for achieving optimal SMT results.

How Do Framed Stencils Enhance SMT Production?

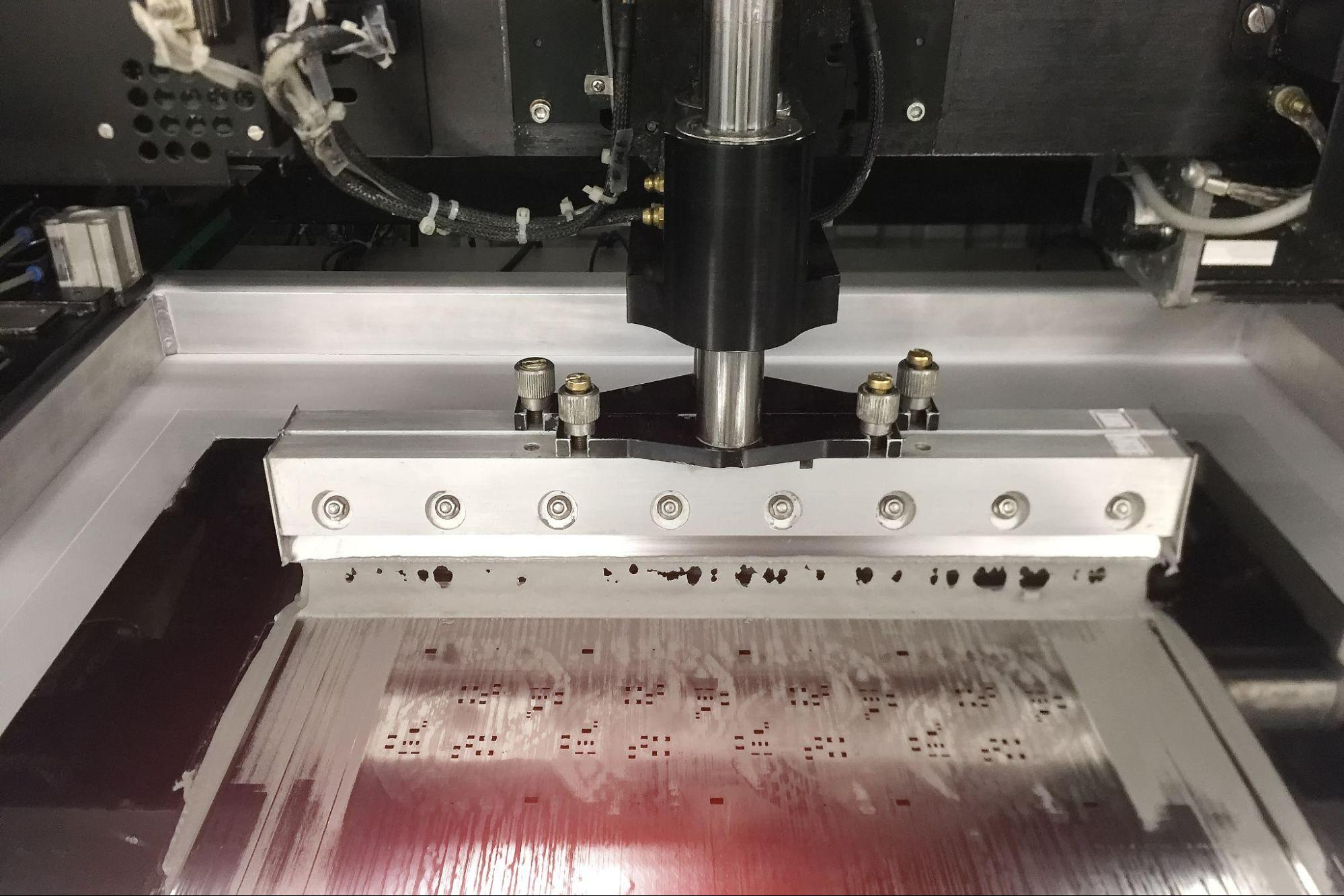

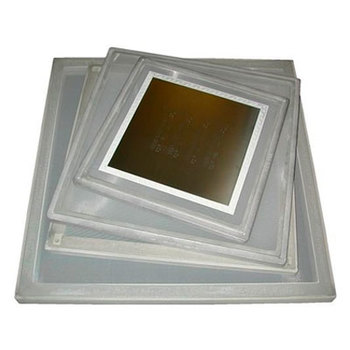

Framed stencils consist of a stainless steel foil permanently affixed to a rigid aluminum or steel frame. This frame maintains the stencil's tension and stability throughout the solder paste printing process. These stencils are commonly integrated into automated SMT assembly lines, where consistent accuracy and repeatability are paramount.

Designed to interface seamlessly with specific stencil printers, framed stencils ensure precise alignment with the PCB. Their robustness makes them a preferred choice for high-volume manufacturing, as they can withstand extensive use without deforming or losing their accuracy.

Key Benefits of Framed Stencils

● Exceptional Durability: The inherent rigidity of the frame prevents the stencil from bending or warping, even after countless print cycles. This resilience makes framed stencils ideal for demanding, long-term SMT production.

● Superior Precision: A consistently taut surface guarantees uniform solder paste deposition, significantly lowering the risk of defects. Studies indicate that maintaining consistent paste volume can boost yield rates in large-scale production.

● Operational Ease: Framed stencils are straightforward to handle and align in automated printing equipment, reducing setup times and minimizing potential operator errors.

● Broad Compatibility: They are engineered to integrate smoothly with most standard stencil printing machines, establishing them as a dependable option for professional manufacturing setups.

Disadvantages of Framed Stencils

● Higher Initial Cost: Due to additional materials and the more complex manufacturing process for the frame, framed stencils typically incur a higher cost, often 20-30% more than their frameless counterparts.

● Increased Storage Requirements: Their bulky frame necessitates more storage space, which can be a challenge for facilities with limited room.

● Limited Design Flexibility: Once produced, a framed stencil is fixed. Any design modifications usually require the procurement of an entirely new stencil, adding to project expenses.

What Are Frameless Stencils and Their Applications?

Frameless stencils, also known as unframed or foil stencils, are individual stainless steel sheets that do not have a permanently attached frame. They are designed to be used with a reusable tensioning system or frame during the printing process. These stencils are frequently employed in prototyping, small-batch production, or environments where adaptability is prioritized over high-volume output.

Being lightweight and easy to store, frameless stencils offer a practical solution for smaller operations or when multiple PCB designs need to be processed quickly.

Advantages of Using Frameless Stencils

● Cost Efficiency: Without the need for a permanent frame, frameless stencils are generally less expensive to produce and purchase, potentially saving up to 30% compared to framed options.

● Compact Storage: The absence of a bulky frame means frameless stencils require significantly less storage space, allowing multiple foils to be stacked efficiently, which is ideal for smaller workspaces.

● Greater Flexibility: They can be adapted to various tensioning systems or reusable frames, facilitating rapid changes between different PCB designs without needing a completely new stencil setup.

● Ideal for Prototyping: For short production runs or testing new PCB layouts, frameless stencils offer an economical starting point without the larger investment associated with framed solutions.

Potential Drawbacks of Frameless Stencils

● Reduced Durability: Lacking a fixed frame, frameless stencils are more susceptible to bending or damage during handling, especially after extensive use.

● Precision Sensitivity: If not correctly tensioned within a reusable frame system, the stencil might sag or misalign, leading to inconsistent solder paste application. This can potentially increase defect rates.

● Extended Setup Time: The process of mounting a frameless stencil into a tensioning system can be more time-consuming compared to using a pre-framed option, which might slow down high-speed production environments.

Which Stencil Type Is Best for Your SMT Production Needs?

The optimal choice between framed and frameless stencils depends significantly on factors such as production volume, budget, and design complexity. Framed stencils are typically the go-to for large-scale, automated production due to their robust design and consistent performance. They excel in environments where thousands of boards are produced daily and where complex designs with fine-pitch components demand exceptional stability for accurate paste application.

Conversely, frameless stencils provide a flexible and cost-effective alternative for prototyping or small-to-medium batch production (e.g., under 1,000 boards). Their lower upfront cost makes them attractive for startups or projects with budget constraints, and their adaptability is invaluable when frequent design changes are necessary. The key is to evaluate the specific demands of your project to align with the strengths of each stencil type.

Enhancing Stencil Performance in SMT Assembly

Regardless of whether a framed or frameless stencil is chosen, implementing best practices for handling and maintenance is crucial for extending its lifespan and optimizing print quality.

Practical Tips for Stencil Care

● Consistent Cleaning: Clean the stencil after every 5-10 prints to prevent solder paste accumulation. Use a dedicated stencil cleaner or isopropyl alcohol with a lint-free cloth to avoid contamination.

● Appropriate Storage: Store framed stencils vertically to prevent frame warping. Frameless stencils should be kept flat within protective sleeves to avoid bending or damage.

● Tension Verification (for Frameless Stencils): When using a frameless stencil, always ensure the tensioning system applies uniform pressure across the foil. Uneven tension can significantly compromise print quality.

● Regular Inspection: Periodically examine both types of stencils for any signs of wear, such as scratches, dents, or worn apertures. Even minor damage can lead to a notable reduction in paste transfer efficiency.

Making an Informed Decision for Your SMT Assembly

Selecting the appropriate stencil—framed or frameless—for your SMT assembly operations is a critical decision influenced by your specific project requirements, available budget, and production scale. Framed stencils offer unparalleled durability and precision, making them the preferred choice for high-volume, automated manufacturing settings. In contrast, frameless stencils present a more economical and flexible option, ideal for prototyping, smaller production runs, or projects with frequent design iterations.

By thoroughly assessing the advantages and disadvantages of each stencil type, you can confidently choose the solution that best aligns with your production objectives. An informed stencil choice will contribute to consistent solder paste application, a reduction in defects, and ultimately, the production of higher-quality PCBs. AIVON is dedicated to supporting your SMT assembly endeavors by offering a range of high-quality stencil solutions tailored to meet the demands of your next PCB production run.