Why Does Squeegee Selection Matter for Solder Paste Printing?

Squeegee selection is a pivotal factor in the stencil printing phase of PCB assembly, directly influencing the quality and consistency of solder paste application. This tool is responsible for precisely spreading solder paste across a stencil, pushing it through apertures onto the designated pads of a printed circuit board. An informed choice in squeegee type and its correct setup can dramatically reduce common defects, such as insufficient paste or bridging between pads, thereby enhancing the overall reliability of electronic assemblies.

The critical role of the squeegee extends to controlling the volume, uniformity, and accuracy of the paste deposit. When the wrong squeegee is used, or settings are not optimized, manufacturers often encounter issues like uneven paste distribution, skipped pads, or excessive paste, all of which contribute to soldering failures during the subsequent reflow process. Therefore, dedicating attention to squeegee material, design, and operational parameters is essential for achieving consistent paste volumes, minimizing material waste, and elevating the quality of PCB assembly.

Understanding Solder Paste Application in Stencil Printing

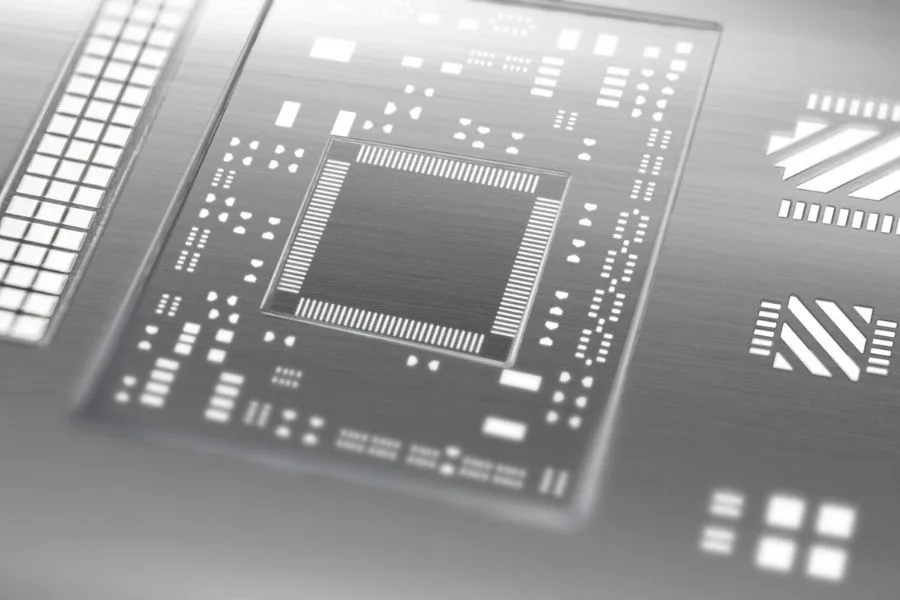

Before delving into specific squeegee types and their applications, it's beneficial to grasp the fundamental mechanics of stencil printing. This process begins with aligning a precision-cut metal stencil, featuring apertures that precisely match the PCB’s solder pads, over the bare circuit board. Solder paste, a carefully formulated blend of microscopic solder spheres and flux, is then dispensed onto the stencil.

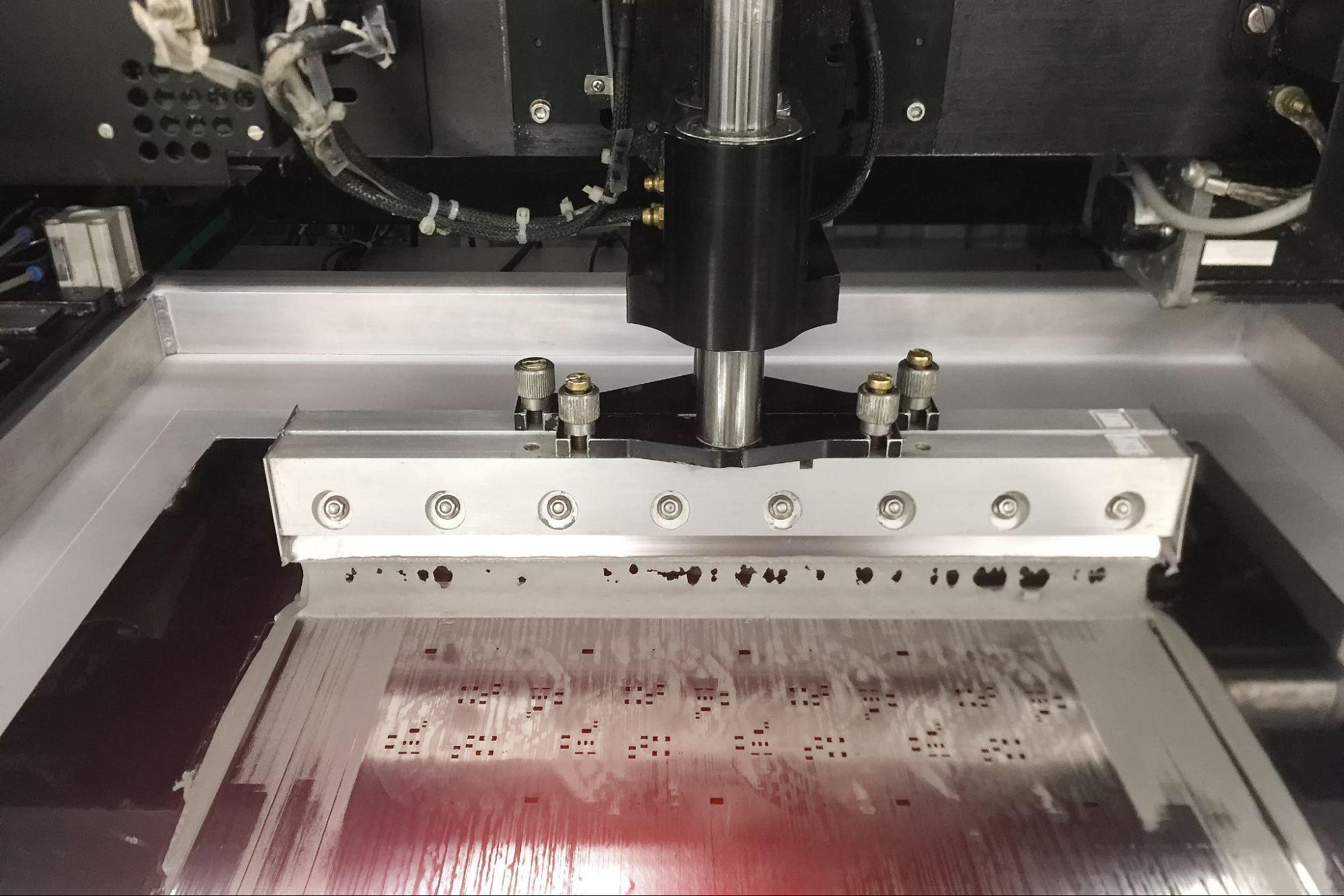

As the squeegee traverses the stencil, it exerts pressure, forcing the solder paste through these apertures and onto the PCB below. Following this, electronic components are accurately placed onto the freshly printed paste, and the entire assembly proceeds to a reflow oven where the solder melts, forming permanent electrical connections. The efficacy of this delicate process hinges on several interdependent variables, including the stencil's design, the solder paste's rheological properties, the printer's calibration settings, and, crucially, the squeegee’s characteristics. Any imbalance among these elements can precipitate common issues such as solder bridging, where paste inadvertently links adjacent pads, or insufficient paste, which leads to compromised joint strength. The squeegee's control over print speed, angle, and pressure is paramount, directly influencing the precision and consistency of the solder paste volume deposited.

What Are the Key Considerations When Choosing a Squeegee?

Selecting the most suitable squeegee is not a universal solution but rather a decision based on several critical factors specific to the PCB assembly process. These considerations guide manufacturers in optimizing their stencil printing setup for the best possible results.

Squeegee Material: Metal vs. Polyurethane

The primary material choice for squeegees typically falls between metal (often stainless steel) and polyurethane, each offering distinct advantages based on the application's demands.

● Metal Squeegees: These blades are renowned for their exceptional durability and provide a consistently sharp edge, enabling precise solder paste application. They are especially favored in high-volume production environments where resistance to wear is paramount. Metal squeegees excel with fine-pitch components (e.g., 0.4mm pitch or smaller) due to their ability to maintain uniform pressure across the stencil, ensuring accurate paste transfer. However, their higher cost and the necessity for careful handling to prevent stencil damage are notable considerations.

● Polyurethane Squeegees: Fabricated from a flexible plastic, polyurethane squeegees are gentler on stencils, making them a popular option for prototyping or smaller production runs. They are available in various hardness levels, measured in durometer (typically ranging from 60-90), allowing for customization according to solder paste viscosity and stencil type. Softer blades (lower durometer) are better suited for thicker pastes, while harder blades perform optimally with thinner pastes. A polyurethane squeegee with a durometer of 70-80 offers a balanced performance for most standard surface-mount technology (SMT) applications involving mid-range pitch components (0.5mm to 1.0mm).

Optimizing Squeegee Angle and Pressure

The angle at which the squeegee engages the stencil significantly impacts paste deposition. An angle between 45 and 60 degrees is commonly recommended, as it promotes efficient paste rolling and thorough aperture filling without applying excessive force. Conversely, an angle that is too steep (approaching 90 degrees) can cause paste smearing or skipped apertures, while an overly shallow angle may fail to push an adequate amount of paste through.

Pressure is equally vital. Applying excessive pressure risks damaging the stencil or causing solder paste to bleed beneath aperture edges, leading to defects. Conversely, insufficient pressure can result in incomplete filling of apertures. Modern stencil printers provide precise control over pressure settings, typically within a range of 0.5 to 2.0 kg per centimeter of squeegee length, adjusted based on the specific solder paste and stencil thickness.

Selecting the Correct Squeegee Size

The squeegee's length must be appropriately matched to the stencil's dimensions to ensure complete coverage in a single pass. Ideally, the squeegee should extend slightly beyond the stencil's width; for example, a 300mm wide stencil would pair well with a squeegee between 320mm and 350mm long. A squeegee that is too short will inevitably leave unprinted areas, whereas an excessively long one can lead to uneven pressure distribution across the stencil, affecting paste consistency.

Exploring Different Squeegee Designs for Stencil Printing

Beyond material composition, squeegees are engineered in various designs, each tailored to specific requirements within PCB assembly. Understanding these distinct types is key to fine-tuning the stencil printing process for consistent solder paste application.

Flat Squeegees

Flat squeegees represent the most prevalent design, characterized by a straight, uniform edge. Their versatility makes them suitable for standard SMT applications, particularly those utilizing consistent stencil thicknesses (typically ranging from 0.1mm to 0.15mm). These squeegees deliver even pressure distribution and are straightforward to set up, establishing them as a default choice for many assemblers.

Diamond or Angled Squeegees

Featuring a distinct diamond or angled profile, these squeegees are engineered to enhance paste rolling dynamics and minimize the amount of solder paste residue left on the stencil following each pass. They prove particularly advantageous for high-density boards incorporating fine-pitch components, as their unique edge geometry facilitates more effective filling of minute apertures.

Trailing Edge Squeegees

Trailing edge squeegees incorporate a slight curve or a secondary edge that trails the primary contact point. This innovative design is aimed at further reducing paste residue on the stencil, thereby decreasing the frequency of cleaning cycles and promoting greater print consistency over extended production runs. For fine-pitch applications (below 0.5mm), exploring diamond or trailing edge squeegees can significantly improve aperture filling and help mitigate defects such as bridging.

Best Practices for Optimizing Stencil Printing in PCB Assembly

While squeegee selection is foundational, achieving consistently high-quality solder paste application requires a holistic approach to the entire stencil printing process. Implementing the following strategies can significantly enhance your PCB assembly workflow and minimize defects.

Matching Squeegee to Stencil Thickness

The thickness of the stencil, typically between 0.08mm and 0.2mm, directly determines the volume of solder paste deposited. Thinner stencils (e.g., 0.08mm) are generally used for fine-pitch components to control paste volume, whereas thicker stencils (0.15mm to 0.2mm) are employed for larger components requiring more paste. A harder squeegee (higher durometer or metal) is recommended for thinner stencils to maintain control over small apertures, while a softer squeegee is better suited for thicker stencils to accommodate higher paste volumes without applying excessive pressure.

Controlling Print Speed

The speed at which the squeegee traverses the stencil critically affects paste consistency. A typical print speed ranges from 20 to 70 mm per second. Slower speeds (closer to 20 mm/s) generally allow for superior aperture filling in fine-pitch designs. Conversely, faster speeds (up to 70 mm/s) are often more efficient for larger components and quicker production cycles. It is advisable to conduct tests with varying speeds on your specific printer to identify the optimal setting for your unique setup.

Regular Maintenance and Cleaning

Squeegees, particularly those made of polyurethane, are subject to wear and tear, which can manifest as nicks or uneven edges over time. Regular inspection of the squeegee for signs of wear is crucial; any inconsistencies in the edge warrant replacement. Furthermore, cleaning the squeegee after each print cycle is imperative to remove residual paste, which can otherwise lead to inconsistent application. A lint-free cloth paired with an appropriate solvent should be used to maintain the blade's optimal condition.

Monitoring Solder Paste Properties

The viscosity and particle size of the solder paste profoundly influence squeegee performance. Pastes characterized by smaller particle sizes (e.g., Type 4 or Type 5, with particle diameters of 20-38 microns or 15-25 microns, respectively) are typically utilized for fine-pitch applications and necessitate a firmer squeegee to ensure proper transfer. Conversely, thicker pastes intended for larger components may perform better with a softer blade to prevent aperture clogging. Always adhere to the paste manufacturer's recommendations and adjust your squeegee choice accordingly to ensure compatibility and optimal results.

Addressing Common Stencil Printing Issues with Squeegee Selection

Even with a meticulously configured setup, stencil printing can present various challenges. The appropriate squeegee selection, coupled with optimized settings, can effectively mitigate many common issues encountered in PCB assembly.

Resolving Insufficient Paste Deposition

When apertures fail to fill adequately, leading to insufficient paste deposition, consider adjusting the squeegee parameters. Switching to a softer polyurethane squeegee or modifying the contact angle to approximately 45 degrees can enhance paste rolling and facilitate better aperture filling. A slight increase in pressure, for instance, by 0.2 kg/cm , may also prove beneficial in ensuring complete paste transfer.

Preventing Solder Bridging

Solder bridging, characterized by excess paste linking adjacent pads, often stems from either excessive squeegee pressure or a worn blade edge. To counteract this, opt for a harder squeegee material or reduce the applied pressure to gain better control over the paste volume. This adjustment helps prevent paste from bleeding under the stencil and creating unwanted connections.

Mitigating Stencil Damage

Harsh metal squeegees or the application of excessive pressure can inflict scratches or dents on stencils, especially thinner ones. To minimize wear and tear on delicate stencils, it is advisable to choose a polyurethane squeegee with a moderate durometer rating (typically 70-80). This choice offers a balance between effective paste transfer and protection for the stencil, prolonging its lifespan and maintaining print quality.

Advanced Strategies for Enhanced PCB Assembly Optimization

For those aiming to elevate their stencil printing capabilities, incorporating advanced strategies can further refine the process, leading to superior outcomes and greater efficiency in PCB assembly.

Conclusion: Mastering Squeegee Selection for Stencil Printing Success

Achieving optimal results in solder paste application during PCB assembly fundamentally relies on a thorough understanding and skillful application of squeegee selection principles. By meticulously evaluating factors such as the squeegee's material (whether metal or polyurethane), its angle and applied pressure, and its specific design type (flat, diamond, or trailing edge), manufacturers can precisely tailor their stencil printing setup to meet the unique demands of their PCB designs.

Integrating these considerations with established best practices—including appropriately matching the squeegee to stencil thickness, carefully controlling print speed, and diligently performing regular maintenance—is crucial for minimizing defects and ensuring consistently reliable outcomes. Regardless of whether the task involves assembling prototypes or scaling up for high-volume production, the judicious choice of squeegee can fundamentally transform the stencil printing process. It is highly recommended to allocate time for experimenting with different squeegee types and settings. Furthermore, integrating advanced analytical tools, such as Automated Optical Inspection (AOI), can provide invaluable precision and feedback. By adopting these comprehensive strategies, one can effectively optimize every facet of PCB assembly, thereby guaranteeing high-quality and consistent outputs in every production run.