Rogers PCBs, renowned for their low-loss performance in high-frequency applications like 5G antennas, radar systems, and aerospace radar, bring unique material properties that demand precise handling during manufacturing. Materials such as the RO4000 and RO3000 series—ceramic-filled PTFE composites—offer dielectric constants from 2.2 to 10.2 and ultra-low loss tangents, but they also introduce challenges like delamination, adhesion failures, and drilling defects that can compromise signal integrity and reliability.

In my consulting work across factories worldwide, I've seen these issues spike defect rates by 10-20% in initial runs, often due to overlooked handling nuances. Drawing from IPC standards and Rogers' processing guidelines, this article demystifies Rogers PCB manufacturing defects, focusing on delamination, adhesion problems, and drilling issues. We'll explore causes rooted in material sensitivity and share approachable, factory-proven fixes to keep your production smooth and yields high. Whether you're scaling prototypes or optimizing volume runs, these strategies ensure your high-performance boards meet IPC-6012 performance specs without the headaches.

What Are Rogers PCBs and Why Do They Present Unique Manufacturing Challenges?

Rogers PCBs refer to circuit boards fabricated using proprietary laminates from Rogers Corporation, such as the RO3000 series (PTFE/ceramic composites for microwave use) and RO4000 series (hydrocarbon/ceramic blends for easier processing). These materials excel in RF/microwave environments, with stable dielectric properties up to 40 GHz and CTEs matched to copper (around 17 ppm/°C in x-y axes) to minimize warpage during thermal cycling.

But their composite nature—blending resins, fillers, and sometimes PTFE—makes them trickier than standard FR-4. FR-4 handles aggressive processes, but Rogers materials are more sensitive to moisture, heat, and mechanical stress, leading to common manufacturing defects. For instance, delamination occurs when layers separate due to trapped vapor, while adhesion problems arise from weak copper-to-laminate bonds. Drilling issues, like excessive smear or hole wall roughness, stem from the abrasive fillers.

These challenges matter because they directly impact electrical performance: a delaminated Rogers PCB can introduce air gaps, shifting the effective dielectric constant and causing insertion loss spikes of up to 1 dB at mmWave frequencies. In production, they inflate scrap costs and delay time-to-market. Per ISO 9001:2015 quality frameworks, addressing them upfront aligns with defect prevention, especially as 5G and mmWave demands push for thinner, denser boards in 2025.

Root Causes of Common Rogers PCB Manufacturing Defects

Understanding the "why" behind these defects starts with Rogers' material chemistry. Let's break down the big three: delamination, adhesion problems, and drilling issues, using real factory observations.

Delamination in Rogers PCBs

Delamination—separation between copper foil, prepreg, or core layers—is a top Rogers PCB manufacturing defect, often triggered during lamination or reflow. The primary culprit? Moisture absorption. Rogers laminates, despite low hygroscopicity (absorbing <0.02% water), can trap vapor if exposed to >50% RH during storage or handling. At lamination temps of 180-200°C, this vapor expands, creating blisters or full separations.

Thermal mismatch plays a role too: RO4000's z-axis CTE (24-31 ppm/°C) exceeds copper's if not balanced, building stress under IPC-TM-650 thermal cycle tests. In one audit, improper vacuum lamination caused 15% delam rates in RO4350B multilayers, exceeding IPC-A-600 Class 3 acceptability.

Adhesion Problems

Poor copper adhesion to the laminate surface leads to peeling or lifting, especially in high-vibration apps like automotive radar. Rogers materials use electrodeposited or reverse-treated foils, but without proper surface prep—like black oxide or alternative oxide—the peel strength drops below 5 lb/in, per IPC-2221B requirements.

Contaminants from handling or inadequate plasma cleaning exacerbate this. For RO3000 series, the PTFE content reduces natural tackiness, demanding specialized bondplies. Factories report adhesion failures in 8-12% of runs when skipping oxide treatments, resulting in open circuits post-etching.

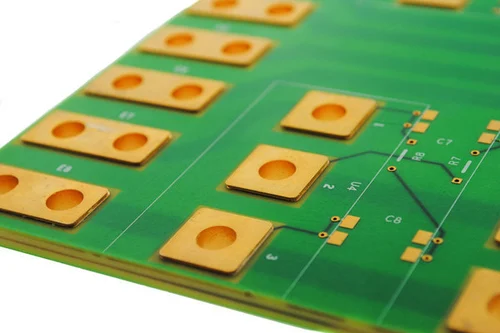

Drilling Issues

Drilling Rogers PCBs risks smear (resin buildup in holes), rough walls, or breakout due to the hard ceramic fillers (alumina or silica). Mechanical drills at high speeds (>100 krpm) generate heat, softening PTFE and causing 20-50 μm smear—far above IPC-6012's cleanliness specs. Laser drilling fares better for microvias but can carbonize edges if parameters aren't tuned, introducing dielectric inconsistencies.

In high-aspect-ratio holes (>6:1), drill wander from material anisotropy adds positional errors up to 0.1 mm, critical for RF signal paths.

| Defect Type | Primary Cause | Typical Impact on Rogers PCBs |

|---|---|---|

| Delamination | Moisture vaporization during heat | Layer separation, signal loss >0.5 dB/mm |

| Adhesion Problems | Inadequate surface treatment | Peel strength <5 lb/in, via failures |

| Drilling Issues | Abrasive fillers causing smear | Hole wall roughness >10 μm, impedance mismatch |

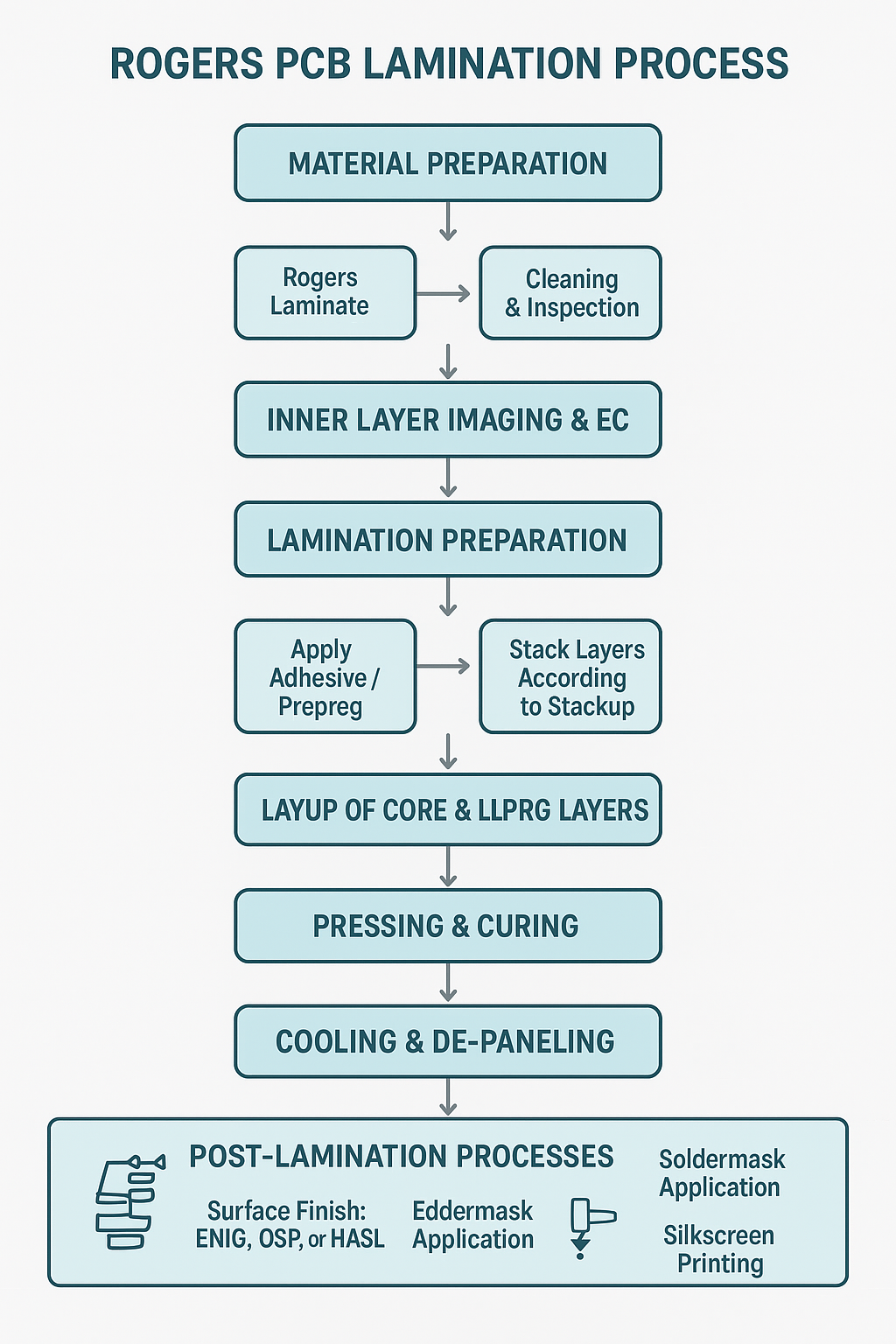

Practical Solutions and Best Practices for Rogers PCB Manufacturing

The good news? These defects are preventable with tailored processes. Here's a friendly, step-by-step guide from factory floors I've optimized, emphasizing Rogers-specific tweaks alongside IPC compliance.

Preventing Delamination

- Storage and Handling: Keep Rogers panels in sealed bags at <40% RH and 23°C. Bake at 105°C for 1-2 hours pre-lamination to reduce moisture below 0.1% (Rogers guideline).

- Lamination Setup: Use vacuum-assisted pressing at 200-300 psi and 180-195°C for 1-2 hours, with slow ramp-down to avoid stress locks. For RO4000, match prepreg thickness to core for uniform flow.

- Post-Process Checks: Perform IPC-TM-650 2.4.24 cross-section analysis on coupons; reject if voids >5% area.

In a recent 2025 project, baking plus vacuum cut delam by 90% in RO3003 multilayers.

Tackling Adhesion Problems

- Surface Preparation: Apply black oxide or micro-roughening to achieve >1 μm texture, boosting peel strength to 8-10 lb/in. For RO3000, use Rogers' 2929 bondply with plasma etching for 20% better adhesion.

- Foil Selection: Opt for low-profile electrodeposited copper (e.g., 1/2 oz) to minimize stress; test per IPC-TM-650 2.4.8.

- Process Integration: Clean with isopropyl alcohol post-desmear, avoiding aggressive plasmas that etch PTFE.

Factories adopting oxide alternatives report zero adhesion lifts in thermal shock tests up to 100 cycles.

Best Practices for Drilling

- Parameter Optimization: For mechanical drilling, use carbide bits at 80-120 krpm and 5-10 m/min feed, with peck cycles every 0.1 mm to clear chips. Pre-drill pilot holes for >0.3 mm vias.

- Smear Removal: Plasma desmear at 200-300 W for 5-10 min, or chemical etch with permanganate—essential for PTFE's smear resistance.

- Laser Alternatives: For vias <0.15 mm, CO2 lasers at 10-20 W with Q-switched pulses prevent heat-affected zones; verify hole taper <5° per IPC-6018.

A table of tuned params for RO4000:

| Material | Drill Speed (krpm) | Feed Rate (m/min) | Desmear Method |

|---|---|---|---|

| RO4003C | 100-120 | 8-12 | Plasma (250 W) |

| RO4350B | 80-100 | 6-10 | Chemical permanganate |

| RO3003 | 90-110 | 7-11 | Plasma + etch |

These yield hole quality under 5 μm roughness, per JEDEC JESD22 standards.

Case Study: Resolving Multi-Defect Runs in a 5G Antenna Prototype

Last year, a client fabricating RO4350B boards for 28 GHz antennas faced cascading issues: 12% delamination, 7% adhesion peels, and smeared vias causing 15% yield loss. Root cause analysis (via IPC-TM-650) pinpointed humidity exposure and mismatched drilling params.

We implemented a full protocol: 24-hour bakes, oxide-treated foils with 2929 bondply, and laser-assisted drilling at optimized pulses. Post-run, delam dropped to 0.5%, adhesion held at 9 lb/in, and via impedance varied <1 Ω. The result? 95% first-pass yields, saving $30K in iterations and accelerating market entry by two months. This mirrors broader 2025 trends, where hybrid mechanical-laser processes cut Rogers defects by 25% industry-wide.

Conclusion

Rogers PCBs unlock breakthrough performance for high-frequency designs, but manufacturing defects like delamination, adhesion problems, and drilling issues can sideline even the best layouts if ignored. By leaning on moisture control, precise surface preps, and tuned machining— all aligned with IPC and Rogers guidelines—you'll sidestep these pitfalls and deliver reliable boards that shine in demanding apps.

From my factory-side view, starting with a solid DFM checklist transforms challenges into strengths. Invest in these practices, and your Rogers projects will not only meet specs but exceed expectations for quality and speed.

FAQs

Q1: What causes Rogers PCB delamination during manufacturing?

A1: Delamination in Rogers materials like RO4000 stems mainly from trapped moisture vaporizing at lamination temps (180-200°C), or CTE mismatches causing stress. Prevention includes baking panels at 105°C for 1-2 hours and vacuum pressing, keeping voids <5% per IPC-TM-650 tests. This approach reduces incidents by 80-90% in controlled environments.

Q2: How do you fix adhesion problems in Rogers PCB production?

A2: Adhesion failures arise from poor copper-laminate bonding; solutions involve black oxide treatment or plasma cleaning to achieve >8 lb/in peel strength (IPC-2221B). For RO3000, use 2929 bondply and low-profile foils. Factories see zero lifts after integrating these with IPA cleaning, ensuring reliability in thermal cycles.

Q3: What are common Rogers PCB drilling issues and best practices?

A3: Drilling defects include smear from ceramic fillers and rough walls; key fixes are 80-120 krpm speeds with peck cycles and plasma desmear (200-300 W). For microvias, CO2 lasers at 10-20 W minimize taper. These align with IPC-6018, yielding <5 μm roughness and stable RF performance.

Q4: How does moisture affect Rogers PCB manufacturing defects?

A4: Moisture absorption (>0.1%) triggers delamination and adhesion loss in hydrophobic Rogers laminates. Store at <40% RH, bake pre-process, and use sealed handling. Per Rogers guidelines, this prevents vapor-induced blisters, maintaining dielectric stability up to 40 GHz.

Q5: Are IPC standards applicable to Rogers PCB quality control?

A5: Yes, IPC-6012 and IPC-A-600 govern qualification and acceptability for Rogers boards, with IPC-6018 for high-freq specifics. They specify peel strength >5 lb/in and void limits <5%, helping factories audit defects like delamination. Compliance boosts yields by 15-20% in RF apps.

References

IPC-A-600 — Acceptability of Printed Boards. IPC – Association Connecting Electronics Industries, 2020.

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2012.

IPC-6012 — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2017.

IPC-6018 — Qualification and Performance Specification for High Frequency (Microwave) Printed Boards. IPC, 2018.

JEDEC JESD22 — Reliability Test Methods for Semiconductor Devices (adapted for PCB via reliability). JEDEC Solid State Technology Association, 2020.

Rogers Corporation. RO4000® Series Laminates Data Sheet. Rogers, 2023.

Rogers Corporation. Fabrication Guidelines for RT/duroid® Laminates. Rogers, 2022.