What Role Do Mouse Bites Play in PCB Manufacturing?

In the intricate process of creating printed circuit boards, "mouse bites" refer to a specific technique used during panelization. This method involves creating a series of tiny, interconnected holes along the perimeter of individual circuit boards, which are arrayed within a larger panel. These perforations allow for straightforward and clean separation of the boards once manufacturing is complete.

Essentially, mouse bites act as predetermined weak points. Their primary function is to enable individual PCBs to be detached from the manufacturing panel without causing damage to the board's functionality or its aesthetic appeal. The term "mouse bites" originated because the small indentations left after separation visually resemble tiny bite marks.

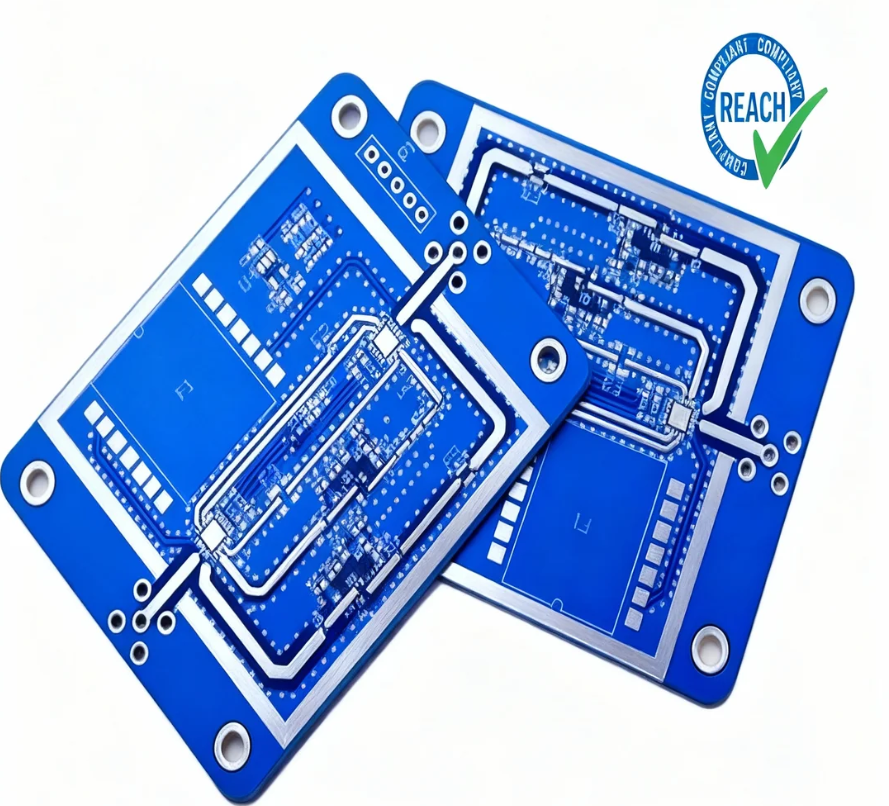

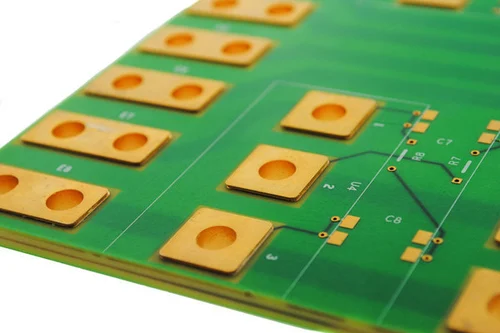

These perforated connections are also commonly known as perforated breakaway tabs or simply PCB breakaway tabs. While typically associated with FR4 panels, their use extends to other substrates, including aluminum PCB boards, though these materials may require a more careful depanelization process due to their inherent thickness and rigidity.

Why Choose Mouse Bites for PCB Fabrication?

The adoption of mouse bites in custom PCB fabrication offers several distinct advantages, primarily aimed at improving manufacturing ease and flexibility. These benefits are particularly pronounced in scenarios like surface mount technology (SMT) assembly, where efficient board separation is crucial.

Benefits of Using Breakaway Tabs

● Simplified Separation: Individual boards can be easily snapped out of a larger panel, often without requiring specialized tools.

● Enhanced Grip: The textured edges resulting from mouse bites can provide a better grip, useful when a board needs to be mounted or inserted into a tight enclosure.

● Economic Depanelization: Especially for small production runs or prototypes, this method can significantly lower labor and tooling expenses, as boards can often be separated by hand.

● Design Adaptability: Mouse bites are highly effective for boards with irregular or non-rectangular outlines, offering greater flexibility compared to straight-line V-scoring.

How Are Mouse Bites Incorporated into PCB Designs?

Integrating mouse bites into a PCB layout requires thoughtful planning to ensure a clean break and efficient processing. For individual PCBs that are part of a larger panel, the mouse bites are typically placed along the edges that connect them.

Placement Strategies for Optimal Results

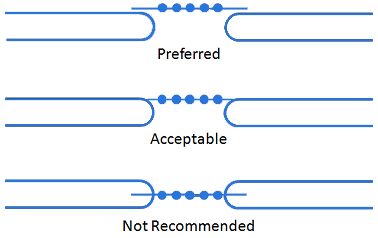

For routed boards, it's common to see mouse bites on both the rail side and the board side. While this method can be slightly more expensive than a simple V-score, it is indispensable for boards with non-rectangular contours. A key objective is to achieve a clean edge post-separation, which is often accomplished by using slight inset perforations. These insets minimize the need for any post-processing cleanup.

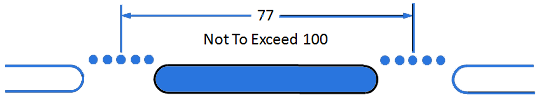

Recommended Spacing Guidelines

Regarding spacing, the distance between the centers of PCB breakaway tabs can vary. A typical range falls between 60 mm and 90 mm, with 77 mm often recommended as a balanced spacing. It's generally advisable not to exceed 100 mm between tabs and to ensure they are evenly distributed across the panel.

The Depanelization Process Using Mouse Bites

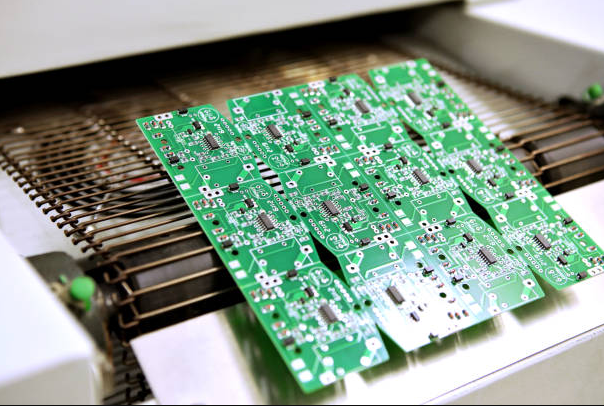

Mouse bites facilitate the panelization process by creating an array of PCBs that can be handled as a single unit during assembly. This method is particularly beneficial for streamlining the workflow.

Step-by-Step Breakdown

1. Arrangement: Multiple individual PCBs are arranged and interconnected within a larger panel, secured by the PCB breakaway tabs.

2. Perforation: These connecting tabs are designed with lines of drilled mouse bite holes, which weaken the material.

3. Separation: After the assembly and soldering phases, the individual boards can be separated, either by hand or using simple tools like pliers. The drilled holes are strategically designed to weaken the connection sufficiently for easy separation while maintaining the panel's structural integrity throughout manufacturing. Inset perforations are preferred to ensure the resulting edge requires minimal to no additional labor for cleanup.

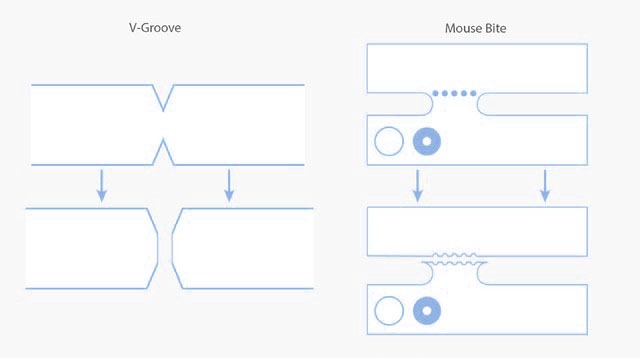

Mouse Bites Versus V-Scoring: A Comparative Look

When deciding on a method for separating PCBs from a panel, two prominent techniques are mouse bites and V-scoring. Each has distinct characteristics that make it suitable for different design and production needs.

V-scoring involves cutting V-shaped grooves into both the top and bottom surfaces of the PCB panel. This method typically results in very smooth edges upon separation and is well-suited for designs that require straight-line breaks. However, V-scoring is less flexible for boards with curved outlines or irregular shapes.

Conversely, mouse bites employ a series of perforated holes, which may leave a slightly rougher or "jagged" edge if not properly designed or post-processed. However, their main advantage lies in their versatility for complex or non-linear board outlines. For applications where perfectly smooth edges are not a critical requirement, mouse bites offer a quicker and more adaptable depanelization option, especially useful in designs with tight spacing or irregular shapes created using laser direct imaging (LDI).

Are Mouse Bites a Cost-Effective Solution?

A significant advantage driving the preference for mouse bites among manufacturers is their inherent cost-effectiveness. This method contributes to reducing overall manufacturing expenses in several ways.

Financial Benefits of Breakaway Tabs

● Standard Tooling: Mouse bites can be created using conventional CNC drilling machines, eliminating the need for specialized cutting equipment often required by other methods.

● Reduced Labor: Boards can frequently be separated manually, lowering labor costs associated with advanced depaneling machinery.

● Optimized Panel Usage: The flexibility of PCB breakaway tab design allows for more efficient utilization of the panel, thereby reducing material waste.

● Ideal for Small Batches: This technique is particularly beneficial for prototyping and low-volume production runs, where minimizing tooling expenditures is a key objective.

Using Mouse Bites in Prototyping and Manual Assembly

For low-volume production environments, such as those found in prototyping, research laboratories, or startup companies focusing on hand-assembled PCBs, mouse bites provide a reliable and economically sound solution.

Advantages for Early-Stage Development

This method bypasses the need for specialized depaneling equipment, as boards can be easily broken apart by hand or with simple pliers. Mouse bites can also be effectively combined with fiducials for precise alignment during assembly. Their utility is especially apparent in the early stages of product development, where considerations like speed, cost, and accessibility are paramount.

Considering the Durability of Mouse Bite Edges

While mouse bites offer many advantages, it's also important to consider the structural integrity of the PCB edges after depanelization. Concerns often revolve around the potential for rough edges or microcracks.

Addressing Potential Issues

Breaking tabs can sometimes leave behind rough edges, which might require a subsequent sanding step to achieve a perfectly smooth finish. There's also a slight risk of microcracks if the separation isn't handled correctly, and the corner strength of boards separated this way might be marginally weaker compared to those that are routed or V-scored. Nevertheless, these potential issues can be effectively mitigated through thoughtful design choices. Strategies include increasing the width of the tabs, reducing the number of mouse bites per tab, and implementing post-break sanding as needed.

AIVON's Expertise in Mouse Bite PCB Manufacturing

AIVON stands as a specialist in delivering comprehensive solutions for PCB manufacturing, encompassing sophisticated panelization techniques. Their deep expertise ensures that whether a design necessitates mouse bites, V-scoring, or a combination of both, the panelization process is optimized for maximum efficiency and board integrity.

AIVON leverages advanced technology and a profound understanding of PCB fabrication to guide clients in selecting the most suitable separation methods for their projects. This customized approach contributes to achieving superior quality outcomes, reducing manufacturing expenditures, and accelerating the market entry for a diverse array of electronic products.