What Exactly Is an Aluminum Printed Circuit Board?

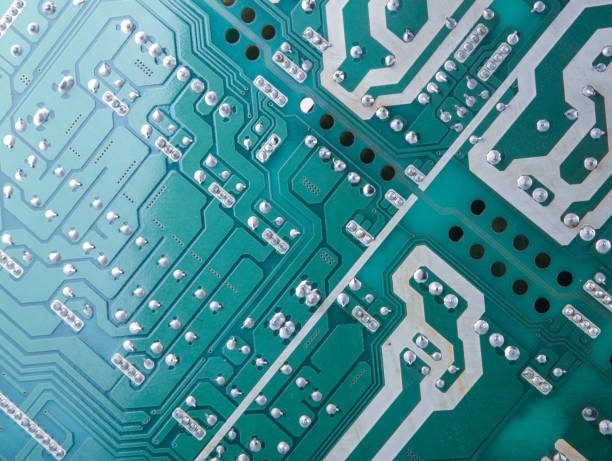

An aluminum Printed Circuit Board (PCB), often referred to as an aluminum circuit board, fundamentally shares its layered structure with conventional PCBs. It comprises layers of copper traces, a solder mask, and a silkscreen. However, its defining characteristic lies in its core material: instead of a fiberglass or plastic substrate, an aluminum PCB features a metal base. This foundational layer is predominantly composed of aluminum, sometimes blended with fiberglass to form a metal-core composite.

These specialized PCBs are most commonly found in single-sided configurations, although double-sided versions are also manufactured. Multilayer aluminum circuit boards, while technically possible, are significantly more complex to produce due to the inherent challenges of integrating multiple metal layers with effective thermal and electrical isolation.

Why Is Aluminum a Preferred Material for Circuit Boards?

Aluminum is extensively utilized in circuit board manufacturing primarily because of its superior ability to dissipate heat away from critical electronic components. This thermal efficiency is crucial for preventing overheating, which can compromise device performance and longevity. The manufacturing process for aluminum PCBs yields boards that are not only excellent at heat transfer but also boast greater mechanical strength and durability compared to traditional fiberglass (FR4) or ceramic substrates.

This combination of efficient thermal management and robust physical properties makes aluminum an ideal material for applications where heat generation is a major concern. By effectively drawing heat away, aluminum substrates contribute to the overall stability and extended operational life of electronic devices.

Key Applications Leveraging Aluminum Substrates

Aluminum PCBs see widespread adoption in applications that generate significant heat. A prime example is LED lighting systems, where the intense light output also produces considerable heat. Aluminum cores efficiently channel this heat away, safeguarding the LEDs and extending their lifespan. You'll find these boards in everything from streetlights and traffic signals to modern household lighting fixtures.

Beyond lighting, aluminum substrates are integral to power conversion electronics, helping regulate currents and manage power flow effectively. Their ability to handle high power densities and dissipate heat makes them invaluable in power converters. While their primary use cases are concentrated in these areas, other industries also employ aluminum circuit boards for specialized thermal management needs.

What Are the Main Advantages and Disadvantages of Aluminum PCBs?

Aluminum circuit boards stand out as one of the most thermally conductive options available for PCBs. Their design prioritizes moving heat away from sensitive components, significantly reducing the risk of heat-induced circuit damage. This high thermal tolerance allows them to support denser circuit layouts and higher power levels than many other PCB types. Furthermore, aluminum substrates are exceptionally durable, offering strong physical resilience that minimizes breakage. From an environmental perspective, aluminum is often considered a more sustainable choice compared to other metals, and its cost remains relatively reasonable.

However, aluminum PCBs also come with certain limitations. Their applications tend to be more specialized compared to standard boards. While they can be a more cost-effective alternative to adding extensive copper conductors for thermal management in a standard board, their initial price is higher than that of basic PCBs without such thermal features. For applications that don't involve significant heat generation, the investment in an aluminum core might not be economically justified. Additionally, if a flexible circuit is required, aluminum core flexible PCBs can typically only bend into their initial configuration and may not withstand repeated flexing or constant vibration stresses.

Design Guidelines for Optimal Aluminum PCB Performance

When designing with aluminum PCBs, engineers must prioritize several key factors to maximize their benefits.

● Thermal Dissipation: Unlike common PCB materials such as FR4 or CEM3, which are poor thermal conductors, aluminum substrates excel at dissipating heat. This capability is critical for preventing high-temperature failures in electronic components, making aluminum PCBs an effective solution for thermal management challenges.

● Thermal Expansion Management: By efficiently managing heat, aluminum core PCBs help mitigate issues related to thermal expansion and contraction among various components on the board. This significantly enhances the overall durability and reliability of the electronic device, particularly addressing concerns in Surface Mount Technology (SMT) assemblies.

● Dimensional Stability: Aluminum substrates offer superior dimensional stability compared to standard insulating PCB materials. Even when subjected to temperature changes (e.g., from 30°C to 140-150°C), the dimensional variation of an aluminum substrate is remarkably low, typically only 2.5% to 3.0%.

● Additional Performance Benefits: Aluminum substrates provide an inherent shielding effect, making them a viable alternative to more brittle ceramic substrates. They also contribute to improved heat resistance, enhanced physical properties, and can help reduce both production costs and labor requirements in certain scenarios.

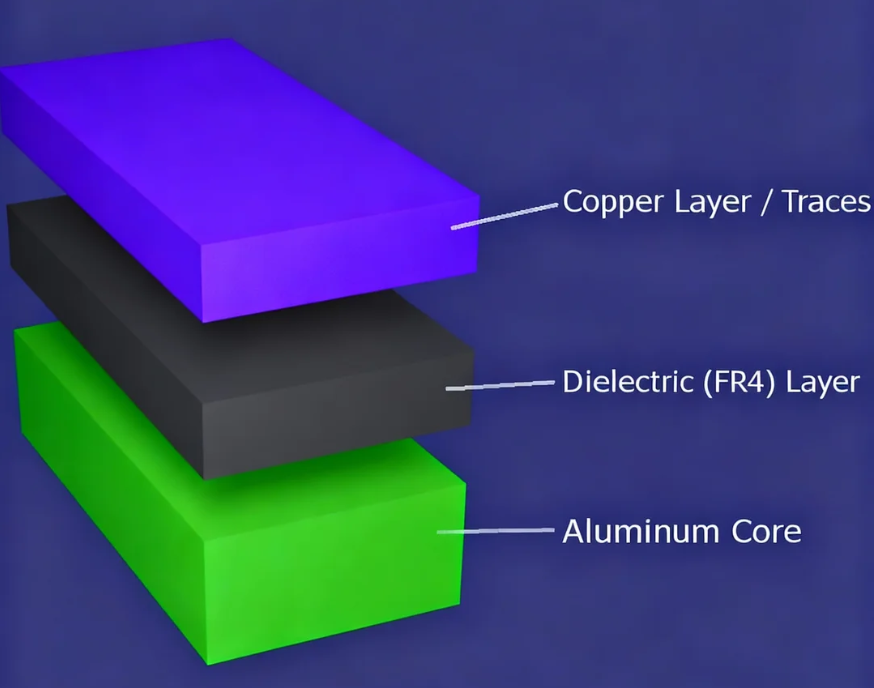

What Is the Internal Structure of an Aluminum PCB?

Aluminum PCBs are essentially aluminum-based Copper Clad Laminates (CCLs), sharing a similar foundational structure with FR4 PCBs. A typical aluminum circuit board is composed of four distinct layers: a copper foil layer, a dielectric layer, an aluminum base layer, and an aluminum base membrane.

● Copper Foil Layer: This layer is generally thicker than those found in standard CCLs, often ranging from 1oz to 10oz. A thicker copper layer allows for a greater current carrying capacity, which is vital for high-power applications.

● Dielectric Layer: Positioned between the copper and the aluminum, this is a thermally conductive yet electrically insulating layer. It typically measures between 50μm to 200μm in thickness, characterized by low thermal resistance, making it crucial for efficient heat transfer.

● Aluminum Base: This is the core of the PCB, providing both mechanical support and superior thermal conductivity. It is made of an aluminum substrate, which is highly efficient at dissipating heat.

● Aluminum Base Membrane Layer: This optional but beneficial layer serves a protective role, safeguarding the aluminum surface from scratches and unintended etching during the manufacturing process. It comes in two main types: one designed for temperatures below 120°C and another high-temperature resistant variant suitable for up to 250°C.

Selecting the Right Dielectric for Aluminum PCBs

The choice of dielectric material is paramount in an aluminum PCB, as it directly influences thermal conductivity, electrical insulation, and breakdown voltage. Designers must carefully weigh the balance between dielectric thickness and thermal resistance, especially for high-power or densely packed designs. Materials with higher thermal conductivity ratings (e.g., 2.0–3.0 W/m·K) facilitate better heat transfer, while thinner dielectrics minimize overall thermal impedance. Concurrently, the selected dielectric must comply with critical safety standards, such as UL94V-0 for flame retardancy and specific dielectric strength requirements.

How Are Aluminum PCBs Manufactured?

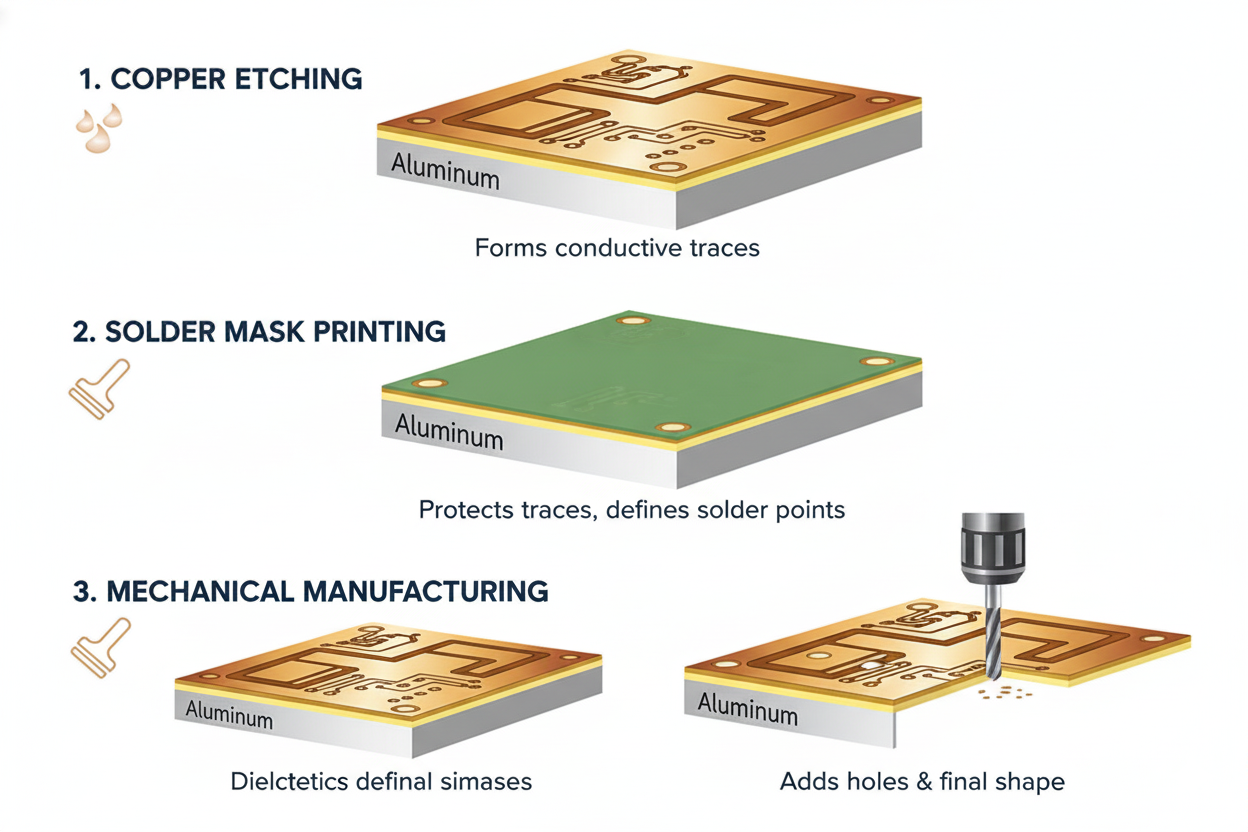

The manufacturing process for aluminum PCBs largely mirrors that of conventional PCBs, but with specific adjustments required due to the unique properties of aluminum and the typically thicker copper layers.

● Copper Etching: Given the comparatively thicker copper foil (often exceeding 3oz) in aluminum PCBs, the etching process demands precise width compensation. Without accurate compensation, the final trace width can deviate significantly from design specifications. Meticulous control of etching factors during manufacturing is essential to maintain tolerance.

● Solder Mask Printing: Applying the solder mask on aluminum core PCBs can be challenging due to the thick copper traces. When the etched copper features create a substantial height difference between the trace surface and the base board, achieving a uniform solder mask layer becomes difficult. To overcome this, a two-stage solder mask printing process is often employed. Using high-quality solder mask oil and, in some cases, an initial resin filling before the solder mask application, helps ensure proper coverage and adhesion.

● Mechanical Manufacturing: Processes such as mechanical drilling, molding, and V-scoring require careful execution. Drilling internal vias can reduce electrical strength if not managed correctly. Therefore, electric milling and specialized milling cutters are often used, particularly for low-volume production. Adjusting drilling parameters to prevent burr formation is also critical for ensuring the integrity of the mechanical manufacturing steps.

Real-World Applications of Aluminum PCBs

Aluminum circuit boards are indispensable across various industries that demand efficient thermal management and robust performance.

● LED Lighting Systems: High-power LEDs generate considerable heat, which aluminum core PCBs effectively dissipate, thereby maintaining brightness and extending the life of the lighting units.

● Power Electronics: Devices like power converters, inverters, and amplifiers require stable thermal platforms to function reliably, making aluminum PCBs an ideal choice.

● Automotive Electronics: From advanced headlight systems to critical battery management units, automotive-grade aluminum PCBs provide the high reliability and resistance to vibration and extreme temperatures necessary for vehicle performance.

● Medical Devices: Precision instruments such as imaging scanners, wearable health monitors, and surgical tools rely on consistent thermal control, which aluminum PCBs reliably deliver.

● Aerospace and Defense: These sectors demand uncompromising performance in harsh environments, where aluminum PCB boards offer exceptional durability and thermal stability.

● Industrial Applications: This includes components like switches, microwave systems, semiconductor devices, thermal insulation, and motor controllers.

● Industrial Vehicles: Applications range from ignition systems and voltage regulators to automatic safety control systems and lighting conversion units.

Why Choose a Specialized Aluminum PCB Manufacturer?

Partnering with an experienced aluminum PCB manufacturer is crucial for achieving high-quality and reliable circuit boards. Manufacturers like AIVON offer comprehensive electronic manufacturing services, encompassing PCB fabrication, component sourcing, SMT assembly, and final testing.

Specialized manufacturers bring decades of expertise to the table, providing full-feature aluminum circuit board capabilities and valuable design for manufacturability (DFM) checks. This ensures that custom aluminum PCBs are produced efficiently, meet stringent quality standards, and stay within cost targets. Their deep understanding of aluminum PCB design and manufacturing processes guarantees dependable performance in demanding sectors such as LED, power, and automotive industries.