Flat wire offers many advantages over traditional windings, but flat-wire motors also have some disadvantages. Overall the advantages outweigh the drawbacks. As technology develops and market penetration increases, the application barriers for flat-wire motors are being addressed one by one.

Application barrier 1: Skin and proximity effects

Skin effect refers to the phenomenon where alternating current or a time-varying electromagnetic field causes the current distribution inside a conductor to be nonuniform, concentrating the current near the conductor surface. Proximity effect occurs when nearby conductors carrying alternating currents influence each other’s magnetic fields, causing nonuniform current distribution in each conductor. Both effects increase AC impedance, which reduces conversion efficiency at high rotational speeds.

Skin effect does not prevent rapid adoption of flat-wire motors, and engineers have proposed several mitigation strategies:

- Increase the aspect ratio of the flat wire to raise the specific surface area.

- Reduce conductor dimensions to increase specific surface area, noting this may reduce slot fill factor and requires trade-off evaluation.

- Use multi-stage gearboxes to lower motor speed; an example application is the Porsche Taycan.

- Use 3D-printed copper conductors, which allow arbitrary conductor cross-sections and internal current-separating structures to limit eddy-current paths and force current into the remaining conductor cross-section. 3D printing also enables arbitrary connection geometries without traditional winding joints. However, this approach is not yet ready for mass production.

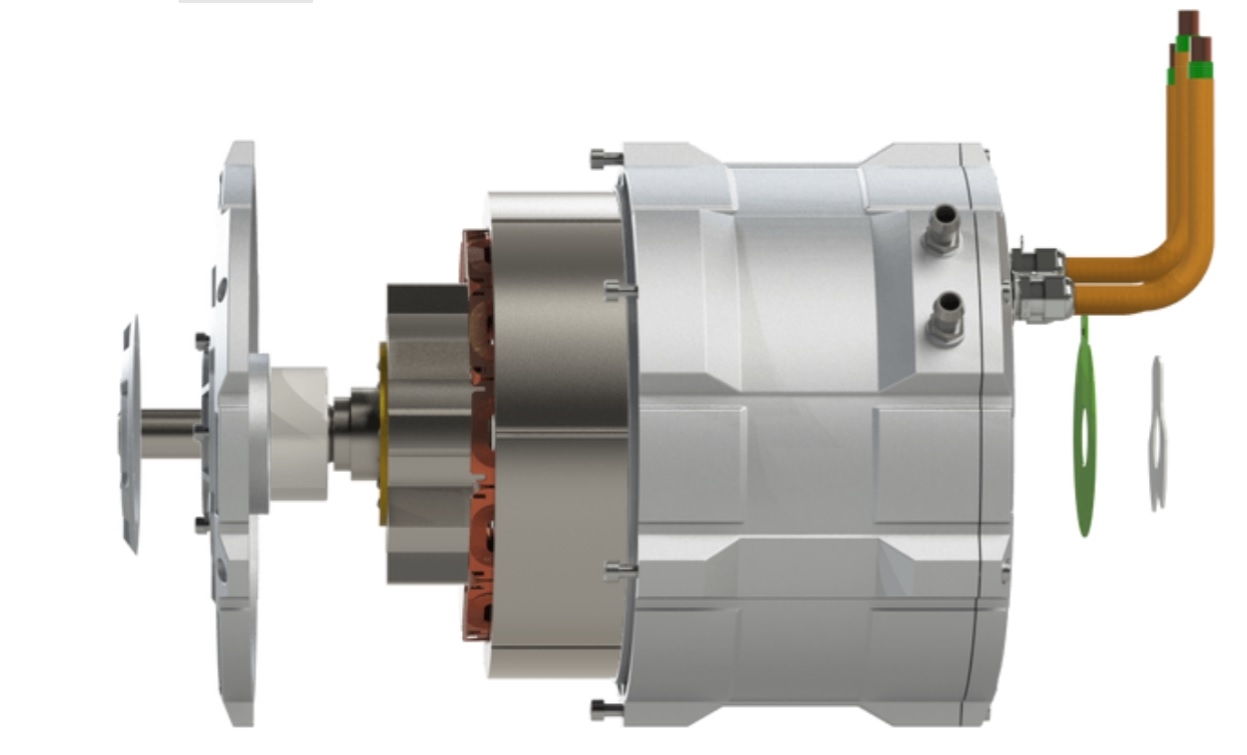

Application barrier 2: Lack of standardization

Different automakers have different design approaches, and the stator is the core of motor design. Once stator dimensions are fixed, any change in conductor shape or size requires custom, expensive tooling. Compatibility is low and series production is challenging.

There is an emerging trend toward series designs within the same automaker or motor supplier. For example, SAIC's E2 architecture considered common-line production from the start: three motors of different power ratings (150 kW, 180 kW, 250 kW) are intended to be compatible across the architecture to maximize modularity. The growth of independent motor suppliers can also ease series-production challenges. Flat-wire motors have higher technical and initial investment thresholds than round-wire motors, so automakers with weaker in-house capabilities often rely on third-party motor suppliers. The limited range of models from these suppliers will tend to dominate the market.

Application barrier 3: Higher production-line investment

Investment for a flat-wire motor production line is 2–5 times that of a round-wire line. Flat-wire motors demand high product consistency and technical capability, requiring high-precision automated servo equipment, welding equipment, hair-pin forming machines, and specialized tooling.

The electrification of vehicles and the trend toward flat-wire motors have attracted capital. For example, a project targeting an annual output of 1 million new-energy vehicle drive motors cited a total investment of 500 million yuan (RMB) and projected incremental sales revenue of 2.5 billion yuan after reaching full capacity.

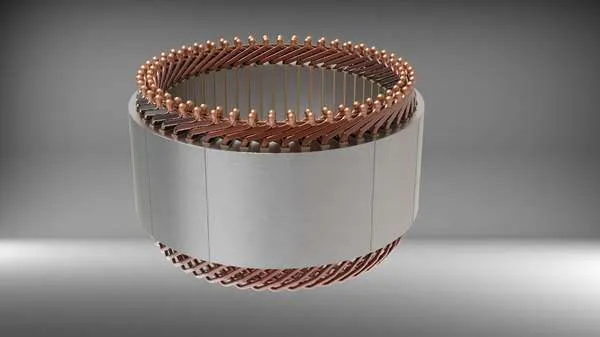

Application barrier 4: Demanding flat-wire requirements and higher material cost

Manufacturing flat wire involves greater difficulty:

- Switching from round to rectangular shapes complicates copper wire production and processing.

- Coating is more difficult. Ensuring uniform insulation at fillet (R) regions is challenging. After drying, the insulating coating can shrink unevenly on flat wire, causing deformation; thicker coating at R regions may be required.

- Bending flat wire into hairpin shapes concentrates stress at the R regions, which can damage the coating.

- High precision is required. Flat wire typically has a larger cross-sectional area and fewer turns, so inconsistency in a single conductor significantly affects overall performance. This raises the consistency requirement and processing costs, increasing the technical premium for flat-wire manufacturers.

- For electric vehicles, the enamelled wire used directly affects vehicle operating stability. This requires strict quality control across multiple process points, including wire drawing and enamel application speeds, coordination between drawing and coating, die configurations for drawing and coating, tension control, baking temperature, varnish viscosity, and working environment.

The largest cost component of flat wire is the raw oxygen-free copper rod; the processing fee contributes relatively little to the motor's overall value. Ensuring a stable supply of qualified product is key to partnerships with automakers. When raw material accounts for the primary cost, automakers have limited incentive to push for lower processing fees from suppliers.