Introduction

Tesla, often seen as a bellwether for new energy vehicles, has proposed using rare-earth-free motors. What does "rare-earth-free" mean in this context, and how much impact could such a shift have on the motor industry?

Rare-earth-free does not mean magnet-free

Industry experts note that calling a motor "magnet-free" simply because it does not use rare earths is inaccurate. Rare-earth permanent magnets are only one way to create the main magnetic field in a synchronous motor. Other approaches can establish the required magnetic field, but a magnetic field is always needed for motor operation. Therefore, the phrase "magnet-free motor" appears to be more of a slogan than a technical description. According to experts, Tesla's plan could follow several paths: replace rare-earth magnets with ferrite magnets, adopt electrically-excited synchronous motors, or use AC induction motors.

Three hypotheses about Tesla's approach

As a leading EV maker, Tesla's choices attract attention across the motor industry. An engineering manager at a well-known industry group offered three hypotheses about Tesla's next-generation rare-earth-free motor. First, "rare-earth-free" might refer specifically to avoiding heavy rare-earth elements rather than excluding all rare-earth elements. In motors, "rare earth" typically refers to heavy rare-earth elements such as terbium (Tb), dysprosium (Dy), holmium (Ho), neodymium (Nd), and praseodymium (Pr). Because heavy rare earths are scarce and expensive, manufacturers have been shifting toward greater use of light rare earths to reduce heavy rare-earth content.

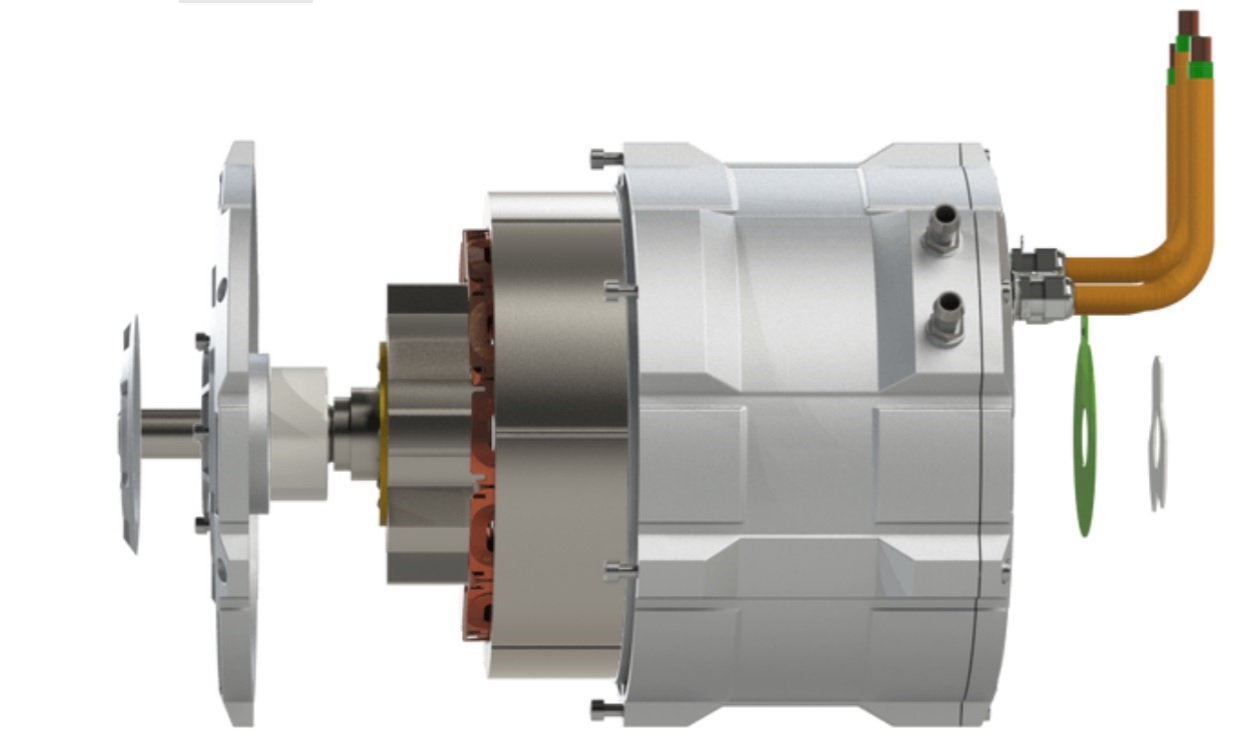

Second, replacing permanent-magnet synchronous motors with electrically-excited synchronous motors is a plausible route. The core idea is to use excitation windings instead of permanent magnets, changing magnetic field strength by adjusting excitation current to meet different performance requirements at various vehicle speeds. Electrically-excited windings avoid the demagnetization and torque-loss issues that permanent magnets can face at high temperatures. Weakening the field at high speed by reducing excitation current enables field weakening and speed variation through excitation control, and can improve safety.

BMW's fifth-generation "magnet-free" motor reportedly uses this approach. The main difference between electrically-excited synchronous motors and permanent-magnet motors is the rotor: the former adds windings on the rotor and introduces excitation current via a brush or slip-ring assembly. This, however, introduces reliability and durability challenges, since brush assemblies can affect operational efficiency and require maintenance.

Third, hybrid excitation is also technically feasible. Hybrid-excited motors use two excitation sources to create the main field, allowing topology changes that can maintain high efficiency while enabling control and adjustment to improve speed control, drive characteristics, or voltage regulation. In such a scheme, permanent magnets might be made from ferrite instead of rare-earth materials, supplemented by electrical excitation. However, ferrite-based schemes typically provide weaker magnetic performance and limited efficiency. Maintaining efficiency may require larger, heavier motor designs. While it is possible Tesla has achieved breakthroughs in new materials, absent such advances, the first hypothesis—reducing or eliminating heavy rare earths while retaining other rare-earth strategies—appears most likely. Some U.S. companies have also developed designs that effectively use zero heavy rare earths, so this is not an insurmountable engineering challenge.

Permanent-magnet motors remain difficult to displace

The electrification of vehicles places new demands on battery, motor, and motor-control development. As market expectations for vehicle performance rise, all-wheel-drive configurations and dual-motor arrangements are increasingly common. How will manufacturers choose between permanent-magnet and induction motors?

Chen Jing, director of motor development at a motor company, said that after industry discussions he reached a common conclusion: permanent-magnet motors remain the market mainstream. Permanent-magnet synchronous motors have been widely used for decades. Early adopters used ferrite materials, whose energy density was only about one-half to one-third that of rare-earth permanent magnets. Since around 2000, the industry has added rare-earth materials to permanent magnets, greatly increasing motor energy density.

From current motor performance, rare-earth permanent-magnet motors have advantages that other motor types struggle to match, so they will continue to be the preferred choice for most new energy vehicle main drive motors. Compared with other types, permanent-magnet motors generate their own magnetic field and require no excitation, avoiding related losses while providing high torque and excellent transmission efficiency. They enable compact, lightweight designs that save chassis space. Their disadvantages include susceptibility to demagnetization at high temperatures and limited real-time speed control.

Electrically-excited synchronous motors and induction motors avoid rare-earth materials and can reduce material cost, but each has trade-offs. Electrically-excited synchronous motors have more complex rotor structures and require slip-ring and brush assemblies, which reduce reliability and increase maintenance requirements. AC induction motors generate magnetic fields by induced currents, which introduces phase lag; however, induction motors typically offer better high-speed performance and are commonly used in all-wheel-drive combinations. For example, the Tesla Model 3 uses an induction motor combined with a permanent-magnet motor for its front- and rear-axle configuration, while some other manufacturers use the reverse arrangement: a front permanent-magnet synchronous motor plus a rear induction motor. Although induction motors can match permanent-magnet motors in efficiency, they require more copper, silicon steel, and other materials, and tend to be larger and heavier, occupying more space; thus they are rarely chosen as the main drive motor in production vehicles.

The product manager at Wolong ZF Automotive Motors, said the consensus is that permanent-magnet motors remain the mainstream for new energy vehicles in the Chinese market. Electrically-excited and induction motors cannot currently match the efficiency of permanent-magnet motors. Global rare-earth supply is sufficient, and it is unlikely that permanent-magnet motors will be displaced in the short term. Many industry participants share this view.