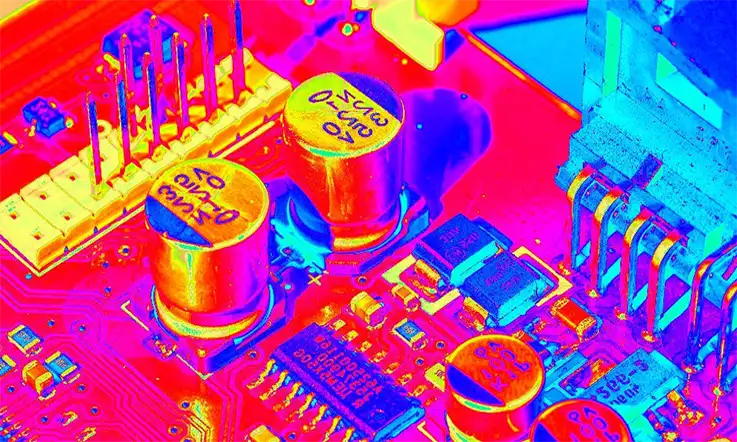

In the demanding world of mining operations, where equipment operates under extreme conditions—temperatures exceeding 80°C, relentless vibrations, and dust-laden environments—reliable thermal management is paramount to preventing equipment failures and ensuring operational continuity. Aluminum PCBs, also known as metal core printed circuit boards (MCPCBs), represent a proven solution for these challenges. By leveraging aluminum's superior thermal conductivity—up to 8 W/m·K compared to FR-4's 0.3 W/m·K—these boards efficiently dissipate heat from power electronics, sensors, and control modules in mining machinery such as drill rigs and conveyor systems. At AIVON, our commitment to high-quality PCB materials ensures that every board meets rigorous standards, supporting the industry's shift toward automation and predictive maintenance. This article explores aluminum PCBs' role in thermal management for mining equipment, highlighting their benefits for heat dissipation and long-term reliability. As mining evolves with 2025 trends toward AI-integrated systems, selecting the right PCB materials can reduce downtime by up to 30% and extend component life.

What Are Aluminum PCBs and Why They Matter for Mining Equipment

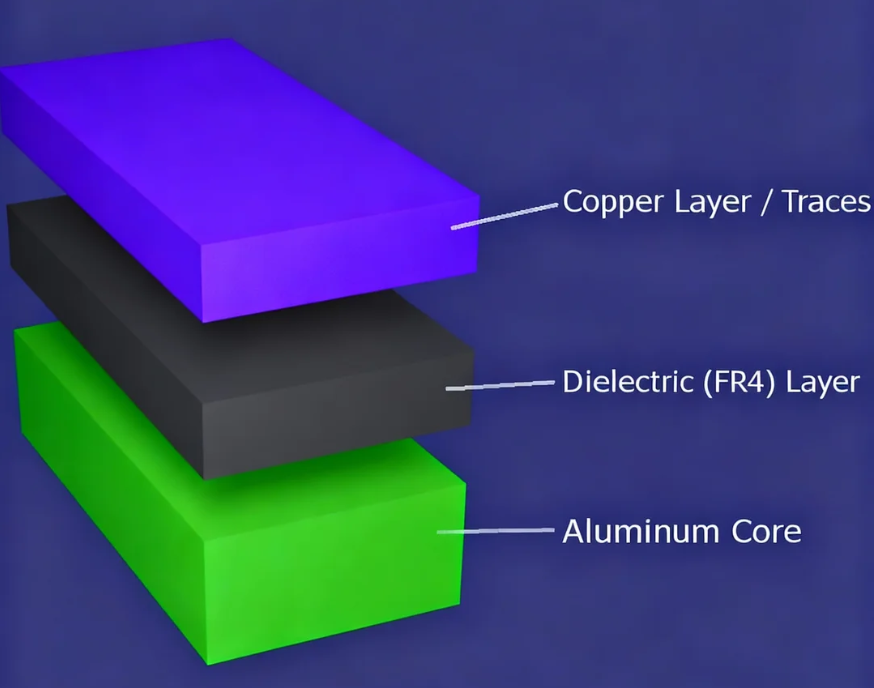

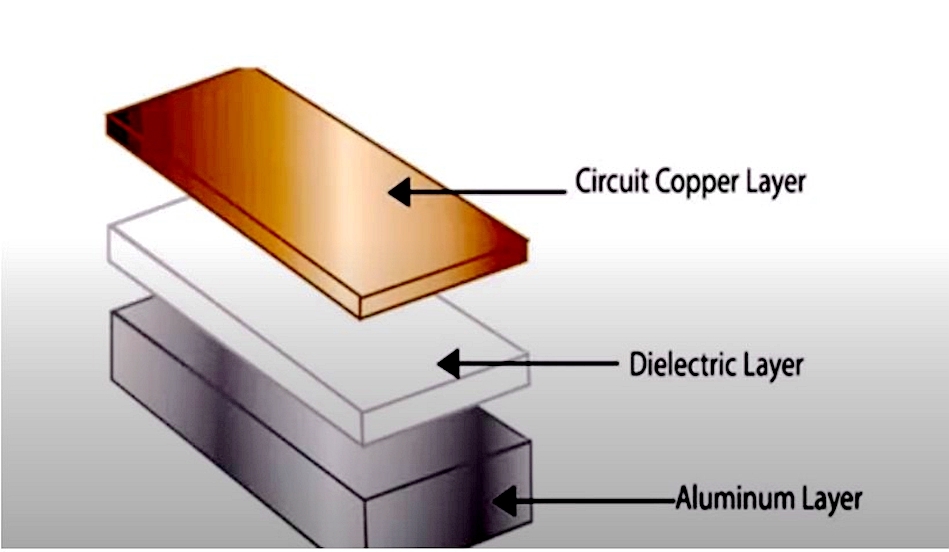

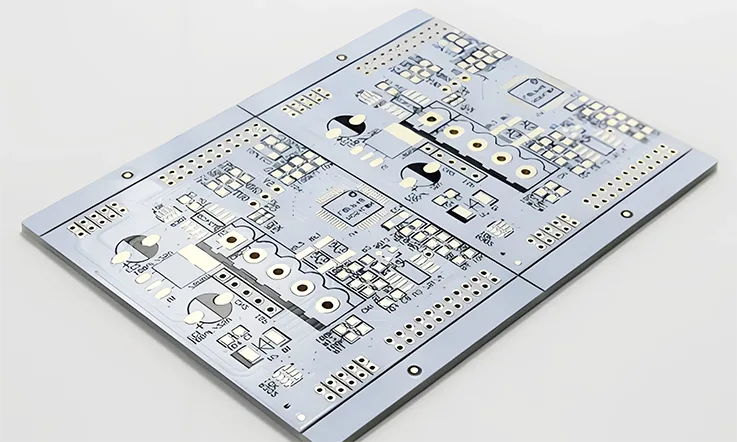

Aluminum PCBs consist of a single or double-sided copper circuit layer bonded to an aluminum core substrate via a thermally conductive dielectric, typically 1-5 mil thick. This construction allows heat generated by high-power components—such as IGBTs in motor drives or LEDs in monitoring arrays—to transfer rapidly to the aluminum base, where it dissipates via natural or forced convection. Unlike traditional FR-4 PCBs, aluminum variants prioritize thermal performance over multilayer complexity, making them ideal for single-layer designs in space-constrained mining applications.

For mining equipment, thermal management is critical due to the sector's harsh operational demands. Equipment like underground loaders or ore crushers generates significant heat from continuous high-load cycles, often leading to thermal throttling or outright failures in control circuits. Aluminum PCBs address this by reducing junction temperatures by 20-30°C, per industry benchmarks, thereby enhancing reliability and compliance with standards like IPC-6012DS for metal core boards. In terms of cost, while initial material expenses are 20-40% higher than FR-4, the extended service life—up to 50% longer in high-heat scenarios—yields substantial ROI through minimized maintenance. As mining embraces 2025's digital transformation, including IoT sensors for real-time monitoring, aluminum PCBs ensure heat dissipation supports uninterrupted data flow, safeguarding productivity in remote sites.

Technical Details: How Aluminum PCBs Enable Superior Heat Dissipation

The efficacy of aluminum PCBs in thermal management stems from their material properties and engineered structure. Aluminum's thermal conductivity (approximately 200-250 W/m·K) far surpasses that of standard PCB substrates, allowing heat to conduct laterally across the core before radiating outward. The dielectric layer, often ceramic-filled epoxy, maintains electrical isolation (up to 5 kV) while offering conductivity of 1-8 W/m·K, bridging the gap between circuit and base without compromising safety.

In mining equipment, where power densities can reach 50 W/cm² in sensor arrays or drive controllers, this setup prevents hotspots that degrade solder joints or silicon chips. According to IPC-2221B guidelines, trace widths for high-current paths (e.g., 10A) can be reduced by 30% on aluminum due to lower thermal resistance, enabling compact designs. Heat dissipation mechanisms include conduction to the aluminum heatsink (integrated or attached), convection via airflow in equipment housings, and radiation enhanced by surface finishes like white solder mask for emissivity >0.9.

Key parameters for mining applications:

- Core Thickness: 0.8-3.2 mm for rigidity in vibrating environments.

- Thermal Expansion Coefficient (CTE): 22-24 ppm/°C, closely matching silicon (3-5 ppm/°C) to minimize stress during -40°C to 125°C cycles.

- Operating Temperature: Up to 150°C continuous, per IEC 61249 standards for laminates.

These attributes ensure compliance with mining-specific quals like ISO 16750 for road vehicles (adapted for heavy machinery), where thermal cycling tests demand <1% resistance change after 1000 cycles.

Practical Solutions: Best Practices for Implementing Aluminum PCBs in Mining Equipment

At AIVON, we advocate a systematic approach to aluminum PCB integration, emphasizing design transparency and material traceability to deliver reliable outcomes. Below are step-by-step best practices, informed by our production expertise and industry standards.

Step 1: Material Selection and Stackup Planning

Choose aluminum cores with at least 2 W/m·K conductivity for moderate heat loads (e.g., sensor boards) or 6-8 W/m·K for power sections. Pair with 1-2 oz copper foil to balance cost and current capacity. For mining's dusty conditions, opt for ENIG surface finish to resist oxidation.

| PCB Material Parameter | Recommended Spec | Benefit for Mining Equipment |

|---|---|---|

| Thermal Conductivity | 2-8 W/m·K | Dissipates 50 W/cm² without >30°C rise. |

| Dielectric Thickness | 75-150 µm | Ensures >2 kV isolation in humid shafts. |

| Copper Weight | 1-3 oz | Supports 20A traces with <10 mΩ drop. |

| Core Alloy | 5052 or 6061 | High strength (yield >200 MPa) for vibrations. |

Verify via thermal simulation tools like Ansys to predict hotspots pre-fab.

Step 2: Design for Optimal Heat Dissipation

Route high-power components over the aluminum core, minimizing vias (aspect ratio <5:1) to avoid thermal bottlenecks. Incorporate thermal relief pads (45° spokes) for soldering, and add cutouts for heatsink mounting. In multilayer hybrids, embed aluminum in inner layers for uniform spread.

For mining equipment, design clearances >0.5 mm for dust ingress prevention, aligning with IPC-A-600 acceptability. Simulate airflow: Target velocity >1 m/s over the board to enhance convection by 40%.

Step 3: Fabrication and Assembly Processes

Fabricate with sequential lamination to prevent warping (<0.75% per IPC-TM-650). Use low-stress adhesives for core bonding, and bake at 120°C/2 hours to remove moisture. Assembly: Employ vapor-phase reflow for even heating, avoiding hotspots in thick dielectrics.

At AIVON, our ISO 9001-certified facilities incorporate 100% AOI inspection, ensuring defect rates <0.1% for thermal vias.

Step 4: Testing and Validation

Conduct thermal cycling ( -40/125°C, 500 cycles) per JEDEC JESD22-A104 to confirm <5% thermal resistance increase. Field-test in simulated mining conditions: 85°C/85% RH with vibration (5-500 Hz, 5G).

These steps, executed with AIVON's precision, guarantee PCBs that withstand mining's rigors.

Procurement Insights: Ensuring Reliability with AIVON Aluminum PCBs

Selecting PCB materials for mining demands partners who prioritize transparency and quality assurance. At AIVON, we source aluminum substrates from certified suppliers adhering to IPC-4101C specifications, providing full material datasheets and RoHS compliance certificates with every order. Our procurement process includes DfM reviews to optimize thermal vias and layer counts, reducing iterations by 25%. For high-volume mining projects, we offer volume discounts and rapid prototyping—typically 7-10 days—backed by a 100% yield guarantee. This corporate commitment ensures your equipment's PCBs not only dissipate heat effectively but also integrate seamlessly into automated systems, minimizing supply chain risks in 2025's volatile materials market.

Conclusion

Aluminum PCBs provide a robust foundation for thermal management in mining equipment, offering unmatched heat dissipation through advanced PCB materials that enhance reliability and efficiency. By reducing operating temperatures and extending component lifespan, they directly contribute to safer, more productive operations in challenging environments. At AIVON, our dedication to standards-compliant manufacturing and transparent procurement empowers mining professionals to select solutions that deliver consistent performance. Invest in aluminum PCBs today for equipment that endures tomorrow's demands.

FAQs

Q1: What are the primary benefits of aluminum PCBs for thermal management?

A1: Aluminum PCBs excel in thermal management with conductivity up to 8 W/m·K, reducing junction temperatures by 20-30°C and improving heat dissipation in high-power applications. This extends equipment life by 50% in harsh conditions, per IPC-6012DS standards.

Q2: How do aluminum PCBs improve heat dissipation in mining equipment?

A2: In mining equipment, aluminum PCBs facilitate rapid heat transfer from components like sensors to the core, minimizing hotspots during 80°C operations. Their CTE match with silicon prevents stress, ensuring reliable performance under vibration.

Q3: What PCB materials are best for mining equipment thermal management?

A3: For mining equipment, aluminum cores with 2-8 W/m·K conductivity and ENIG finishes are optimal PCB materials, offering dust resistance and >2 kV isolation. They comply with IEC 61249 for laminates in extreme environments.

Q4: Why choose aluminum PCBs over FR-4 for high-heat mining applications?

A4: Aluminum PCBs surpass FR-4 in heat dissipation (200x better conductivity), enabling compact designs for mining equipment without thermal throttling. This supports 2025 automation trends, cutting downtime 30% via efficient thermal management.

Q5: How does thermal management impact mining equipment reliability?

A5: Effective thermal management with aluminum PCBs prevents failures from overheating, ensuring <1% resistance change after 1000 cycles per JEDEC JESD22-A104. It boosts overall reliability in dusty, high-vibration mining settings.

References

IPC-6012DS — Qualification and Performance Specification for Single and Double-Sided Metal Core Printed Boards. IPC, 2015.

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2003.

IEC 61249 — Materials for Printed Boards and Other Interconnection Structures and Assemblies. IEC, 1995.

IPC-A-600 — Acceptability of Printed Boards. IPC, Rev. H, 2019.

IPC-TM-650 — Test Methods Manual. IPC, 2023.

JEDEC JESD22-A104 — Temperature Cycling. JEDEC, 2009.