Overview

Exhaust waste heat is an underutilized energy source. Converting it into usable electrical power is an effective way to improve overall energy use. Studies indicate exhaust has relatively high energy quality. Recovering this energy can reduce vehicle energy consumption and CO2 emissions. If exhaust waste heat is fully converted to electricity, CO2 emissions can be reduced by 3%–7%, and under typical operating conditions by about 5%–10%. In foreign tests, applying waste-heat power generation to a Ford 2.5L SUV increased output by 348 W in highway operation, improving fuel economy by 1.5%; under city conditions output increased by 91 W, improving fuel economy by 1.2%. During tests the flow was limited to 40 g/s to reduce exhaust back pressure. Tests indicate additional performance gains can be achieved through materials and system optimization.

Effectively recovering a portion of exhaust energy and converting it into useful work can further improve energy utilization and vehicle overall performance.

1. Current Waste Heat Utilization Technologies

Engine exhaust waste heat recovery technologies include exhaust turbocharging, cabin heating, exhaust gas recirculation, fuel reforming, waste-heat cooling, and waste-heat power generation. Exhaust turbocharging and exhaust gas recirculation are relatively mature. Cabin heating is effective only in cold seasons to improve comfort and cold-start performance, so it does not fully utilize exhaust heat. Fuel reforming applies only to specific liquid fuels. Waste-heat cooling and waste-heat power generation are less mature, but they can operate across seasons and driving conditions. The two systems share many structural similarities and several common challenges.

1.1 Engine Waste-Heat Driven Cooling

Using recovered engine exhaust heat to drive a vehicle air-conditioning system provides an energy-saving cooling solution. The main proposed cooling methods are absorption, adsorption, and ejector refrigeration.

1.1.1 Absorption Refrigeration

Absorption refrigeration uses heat as the driving force. One substance absorbs another and later releases it, causing state changes accompanied by heat absorption and release to complete the refrigeration cycle.

Common working fluid pairs include water–lithium bromide, ammonia–water, and HFC-134a. Water–lithium bromide is frequently used in vehicle systems. The COP (cooling capacity / power input) of absorption systems is higher than that of adsorption systems but lower than vapor-compression systems.

1.1.2 Adsorption Refrigeration

Adsorption refrigeration uses solid materials that adsorb a gas or vapor at one set of temperature and pressure and desorb it at another. The adsorption/desorption processes are accompanied by heat exchange and pressure changes, which perform the role of compression.

Typical working pairs include activated carbon–ammonia, zeolite–water, and zeolite–ammonia. These working fluids are environmentally friendly and can directly use primary heat sources, so the technology has attracted attention. Adsorption systems have few moving parts and high reliability. Using solid adsorbents makes them suitable for environments with vibration.

1.1.3 Ejector Refrigeration

Ejector refrigeration is a heat-driven cooling system that can use low-grade heat such as industrial waste heat or solar energy. The system is simple and avoids lubrication and sealing issues, allowing new low-pollution refrigerants to be used easily.

The cycle works as follows: high-pressure vapor heated in the heater expands adiabatically through a nozzle to form a low-pressure, high-velocity jet that entrains low-pressure vapor from the evaporator and mixes with it. The mixed flow is diffused, pressurized in a diffuser, and then condensed in the condenser. Part of the condensate serves as the refrigerant and is throttled to the evaporator, where it absorbs heat and vaporizes; the remainder is pumped back to the heater to become working vapor again. Apart from the circulation pump, the ejector system has no other moving parts, and the working vapor and refrigerant can be the same substance, eliminating the separation equipment required in absorption systems. The structure is simple and the power consumption is low, and it can utilize low-grade heat, making it suitable for vehicle air-conditioning when waste heat is available. However, the ejector jet generates significant noise, so an efficient silencer is required at the ejector outlet to preserve cabin comfort.

1.2 Engine Waste-Heat Power Generation

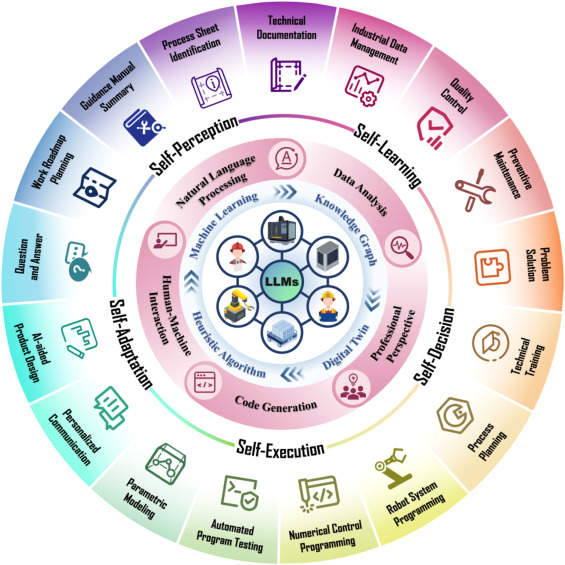

1.2.1 Thermoelectric Generation

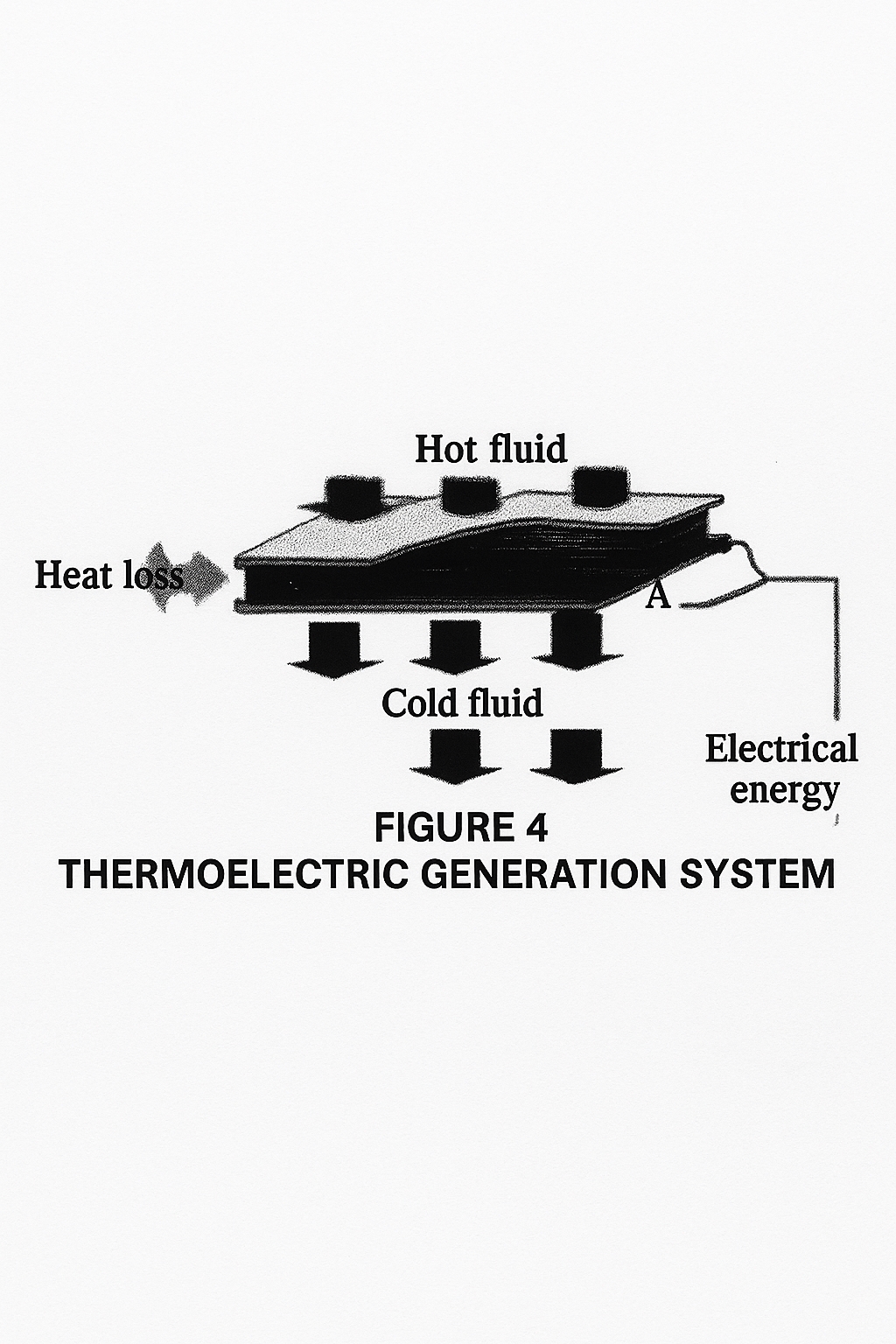

Thermoelectric generation uses N-type and P-type semiconductor materials. One end of both materials is connected to a common conductor placed in the hot exhaust stream, and the other ends are connected to separate conductors at the cold side. The temperature difference causes charge carriers (holes and electrons) to diffuse and create a potential difference under open-circuit conditions, producing positive and negative voltages at the terminals and directly converting heat to electricity.

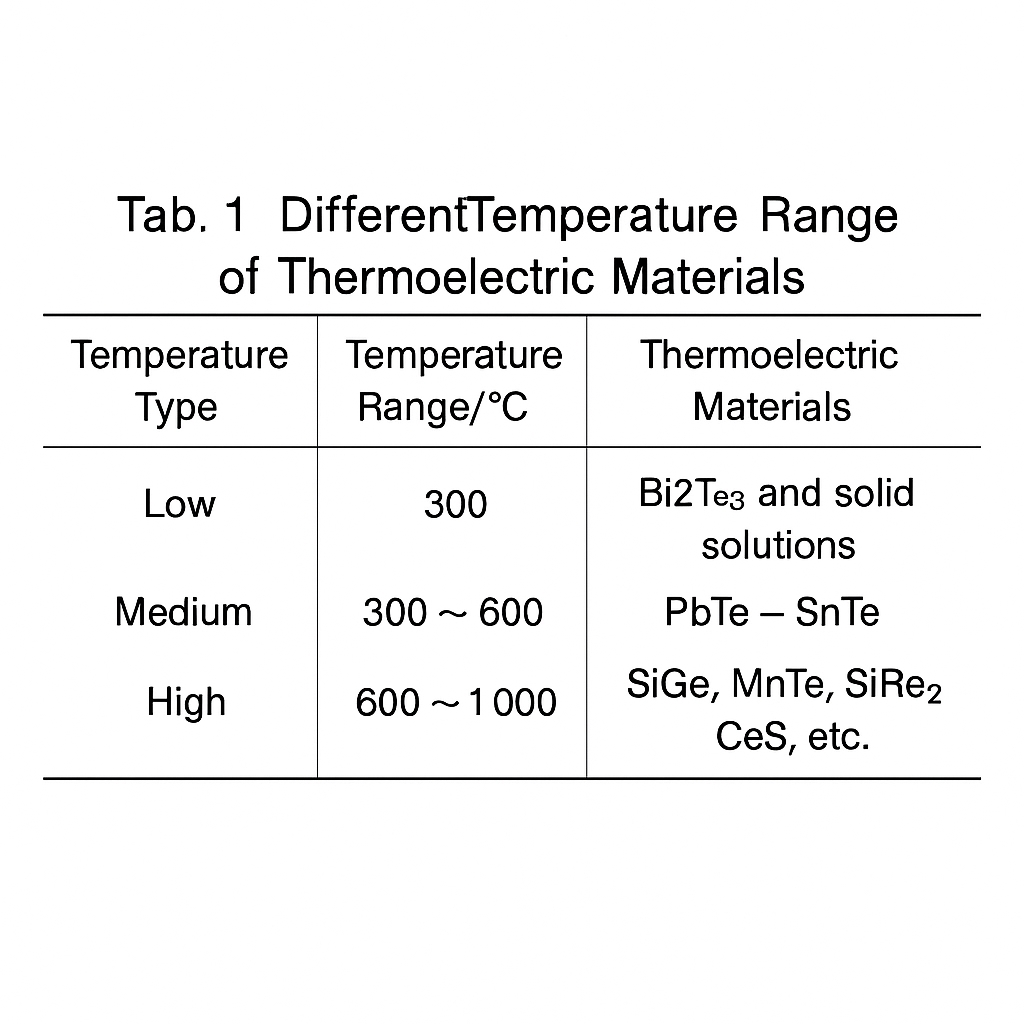

Thermoelectric efficiency depends on the module performance, the temperature difference across it, and the arrangement within the exhaust channel or housing. Most thermoelectric materials are semiconductors, and different materials show higher conversion efficiency over different temperature ranges. A materials performance table is shown below.

1.2.2 Turbine Generation

Exhaust turbine generation uses high-temperature exhaust gas to drive a turbine at high speed, which in turn drives a coaxial permanent-magnet generator to produce electricity. The generated electrical energy can be stored in a battery or used to power vehicle electrical loads.

Coaxial attachments can include a compressor and a permanent-magnet generator, providing both boost and power generation functions for additional energy savings.

Some designs omit the compressor and use the turbine solely to drive a generator. Tests have shown that exhaust-driven turbine generators can supply a vehicle's electrical needs. Although structurally simple and easy to install, turbine recovery may increase exhaust back pressure and negatively affect engine performance, and the recoverable energy from the turbine is limited.

1.2.3 Rankine Cycle Waste-Heat Generation

The Rankine cycle is a steam power cycle. Integrating a Rankine cycle into the engine exhaust system uses exhaust heat to drive the cycle, converting low-grade heat into higher-grade energy such as electricity or mechanical work. Research on using engine waste heat to do work began in the 1980s, with major contributions from Honda, Mitsui Engineering, Cummins, BMW, and others. BMW developed a gasoline-engine integrated steam mechanism called "TurboSteamer" and tested it on a 1.8L 4-cylinder engine used in the 3 Series. That system used high- and low-temperature cycles with water and ethanol as working fluids. Results showed increases in fuel efficiency, output power, and torque by about 15%, 10 kW, and 20 N·m respectively.