Overview

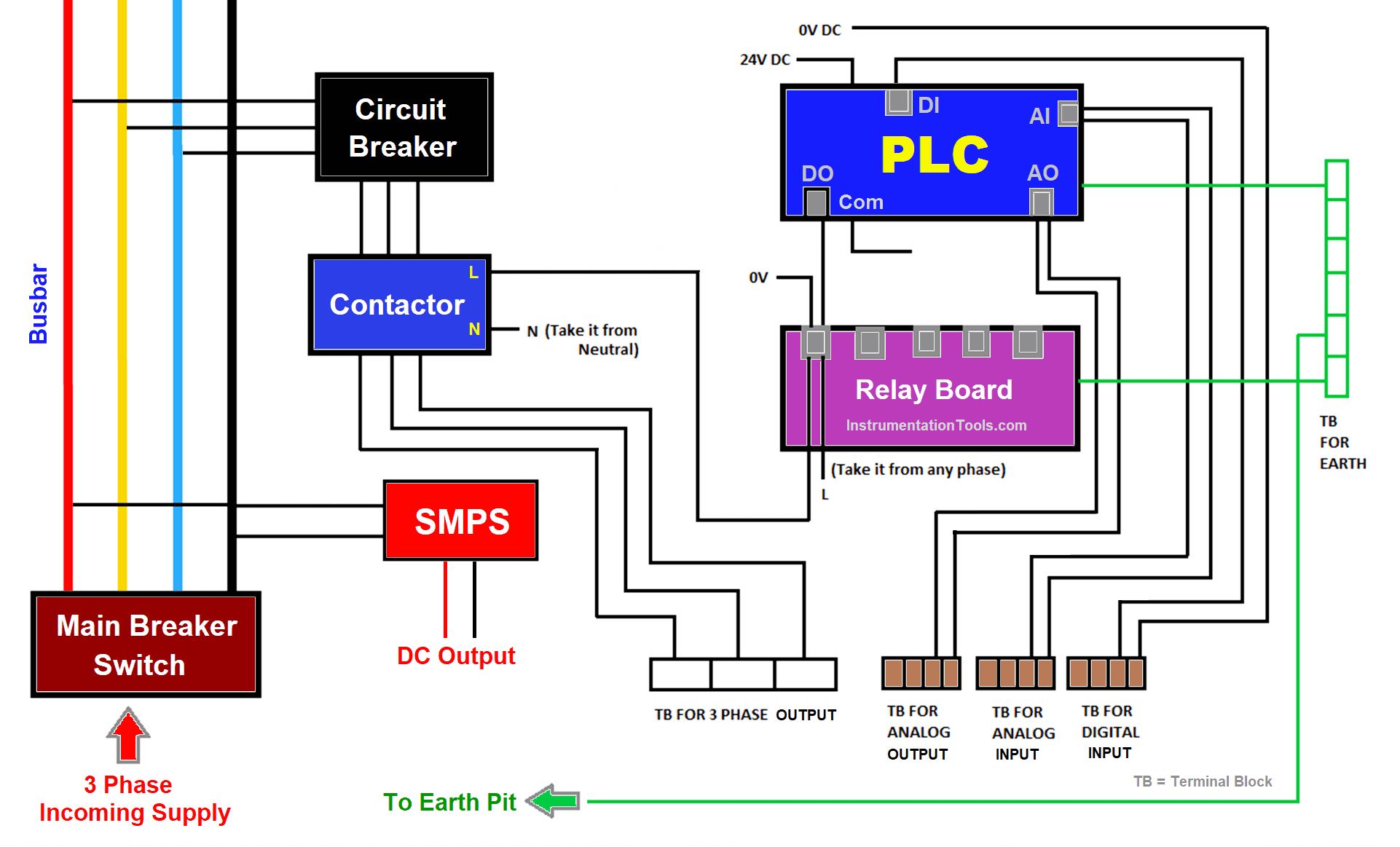

PLC (programmable logic controller) is an electronic device used in automation control systems to monitor and control industrial processes. One common application is to control contactors. A contactor is an electrical switching device that opens or closes high-current loads by energizing or de-energizing an electromagnetic coil. Before discussing whether a PLC can directly drive a contactor, it is necessary to understand contactor characteristics.

How a contactor works

A contactor typically consists of an electromagnetic coil and a set of contacts. When the coil is energized, a magnetic field pulls the contacts closed, allowing current to flow through the contactor. When the coil is de-energized, the contacts open and interrupt the load current. Contactors are designed to handle high-current loads and are therefore used in applications involving large power circuits.

Types of PLC outputs for driving contactors

1. Direct-output PLCs: These PLCs include high-power output modules, often implemented as relay outputs, and can directly drive contactor coils. Relay output modules are generally designed to handle higher currents, so they can be connected directly to a contactor coil without an additional relay or amplifier. Such PLCs are suitable for direct control of contactors.

2. Three-wire output PLCs: These PLCs provide dedicated output modules that may include dedicated output relays plus additional coil drive circuitry. They can be used to control contactors but typically rely on the internal coil drive circuitry to supply the required current and voltage to the contactor coil. These circuits may include output drivers or converters to meet the coil requirements.

3. Low-power output PLCs: These PLCs are generally not suitable for directly driving contactors because their output current capability is low. They are typically intended to control low-power loads or to receive signals from sensors.

Practical considerations

Although some PLCs can directly drive contactors, the following factors must be considered in practice:

- Output current: Different PLC models have different output current capabilities. When selecting a PLC, ensure its output current meets the contactor coil current requirements. If the PLC output current is insufficient, use an additional coil driver or relay amplifier.

- Supply voltage: Contactors often require higher coil voltages, frequently AC, while PLC output voltages may be lower or DC. Before connecting a PLC to a contactor, convert the PLC output signal to a voltage suitable for the contactor coil when necessary.

- Relay module options: Some PLCs offer removable relay modules, allowing module replacement to match different current and voltage requirements.

Conclusion

PLCs capable of directly driving contactors typically include high-power output modules that provide sufficient current and voltage for contactor coils. However, not all PLCs are suitable for this purpose. System designers must verify the PLC's output current and voltage capabilities and consider whether additional coil drive circuitry or relay modules are required.