Overview

Electric motors account for a large share of industrial electricity consumption worldwide. Even modest improvements in industrial motor drive efficiency can significantly reduce global energy use and environmental impact. Stricter efficiency standards are creating new challenges for power electronics designers.

Silicon Carbide and System Efficiency

Silicon carbide (SiC) devices can improve the efficiency of industrial motor drives. Replacing conventional silicon IGBTs with SiC devices in a 25 kW, low-voltage three-phase motor drive produced system-level efficiency gains of about 2.4% in the presented comparisons. Further redesign using SiC enables tighter integration of the inverter and motor, resulting in smaller, lighter embedded industrial drives.

Test Case: 25 kW Drive with SiC Power Modules

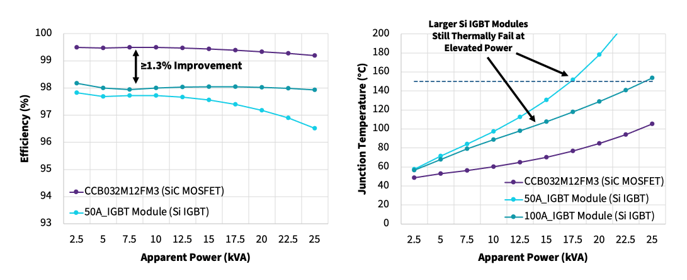

A typical motor drive consists of an AC-DC active front end (AFE) and a DC-AC inverter stage. In a 25 kW drive with a 45 kHz switching AFE, using SiC in the front end instead of silicon switches improved the front-end efficiency by about 1.3% compared with a baseline 20 kHz silicon solution. In conservative benchmarks comparing a Wolfspeed 30 A SiC power module against a 100 A silicon IGBT module (both switching at 8 kHz), the inverter showed a similar improvement. Combined, these changes produced approximately a 2.6% overall system efficiency increase and reduced total system loss by about 50%, enabling an integrated motor to meet a higher efficiency class (IE4) versus the original IE3 class.

Smaller Heatsinks Enabled by Lower Losses

One key benefit of SiC in the inverter is the significant reduction in heat generation, allowing designers to use smaller heatsinks and build smaller, lighter drive systems. Figure 1 shows a comparison for a 25 kW inverter at 8 kHz switching frequency where a SiC MOSFET solution reduced the heatsink volume by 77%: from 1.37 L (0.73°C/W) to 0.31 L (1.6°C/W).

Figure 1: 25 kW inverter, Fsw = 8 kHz, SiC MOSFET heatsink reduced 77%: 0.31 L (1.6°C/W) vs 1.37 L (0.73°C/W).

Thermal Behavior and Operating Margin

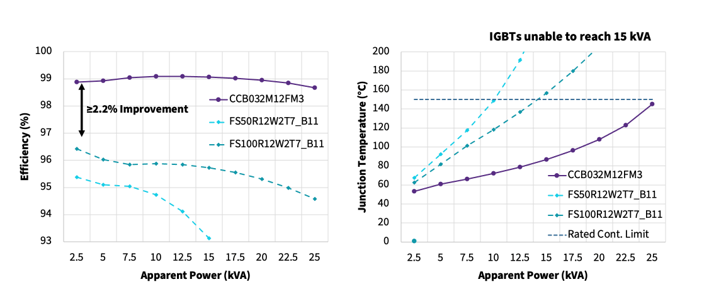

With a 0.8 L heatsink in a 25 kW inverter, a Wolfspeed SiC six-pack WolfPACK module showed higher efficiency than a conventional silicon IGBT module. At higher power levels, 50 A and 100 A silicon IGBT devices experienced increased junction temperature leading to failure, while a Wolfspeed 32 A SiC MOSFET remained stable and stayed well below failure temperature thresholds.

The efficiency improvements were observed not only at peak load but also at partial loads, and in some partial-load conditions the improvements were larger. The tested SiC devices were lower current-rated parts with junction temperature at maximum load around 105°C, providing significant thermal margin relative to a 150°C application limit commonly applied to power modules. In contrast, the 50 A IGBT module was well above that limit and the 100 A IGBT slightly exceeded the maximum load limit.

Figure 2: 25 kW inverter, Fsw = 8 kHz, larger silicon IGBT heatsink 1.37 L (0.7°C/W) vs smaller SiC heatsink 0.8 L (0.99°C/W).

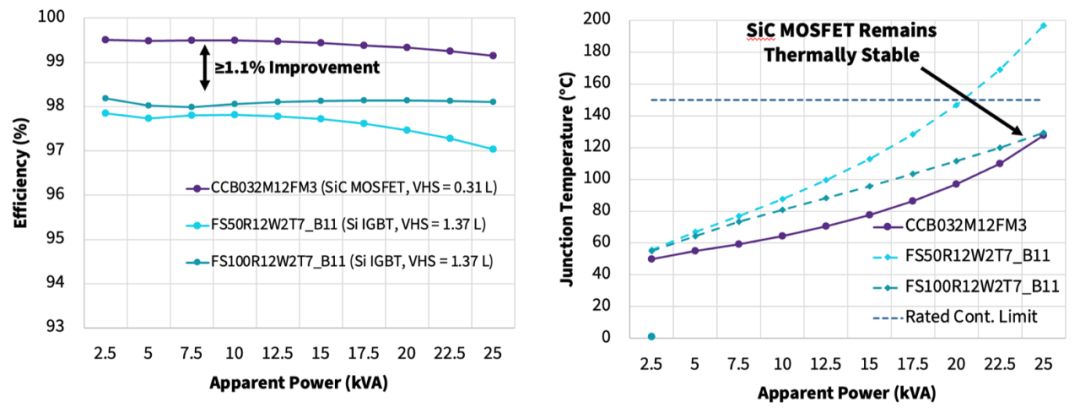

Heatsink Trade-Offs and System Optimization

To ensure feasible and optimized system operation, different heatsink sizes were evaluated. Increasing the IGBT heatsink volume from 0.8 L to 1.37 L and reducing the SiC heatsink size by 61% resulted in similar junction temperatures for the tested parts. After these adjustments, the 32 A SiC device and the 100 A IGBT converged to junction temperatures near 129°C, while the 50 A IGBT remained significantly above 150°C. The SiC inverter efficiency improved by about 1.1% in this scenario. Overall, using a more compact, optimized SiC heatsink in a three-phase 25 kW system yielded a 2.4% efficiency improvement, reduced losses by about 600 W, and moved the integrated motor from IE3 to IE4 efficiency class.

System-Level Cost and Energy Savings

Although SiC devices can have higher upfront costs than silicon IGBTs, their lower losses and ability to operate at higher switching frequencies often reduce the need for passive components and large heatsinks. For the 25 kW system presented, the optimized SiC-based configuration reduced system losses by up to 605 W. Using a representative annual runtime and a typical regional electricity rate (as of November 2023), the energy cost savings were estimated on the order of local utility rates over a 15-year period. When system-level costs are considered, the higher device cost of SiC can be offset by reductions in passive components, heatsink size, and ongoing energy consumption, while producing higher overall drive efficiency.

Figure 3: 25 kW inverter, Fsw = 16 kHz, SiC MOSFET heatsink reduced 41%: 0.80 L (0.99°C/W) vs 1.37 L (0.73°C/W).

Higher Switching Frequency Performance

At higher switching frequency (16 kHz), SiC maintained strong performance while using a heatsink 41% smaller than the comparable IGBT heatsink. Using a Wolfspeed FM3 six-pack SiC module, the inverter efficiency remained at or near 99% and junction temperatures approached the 150°C limit at peak load. For 50 A and 100 A IGBTs, increased switching losses caused thermal failure around 10 kW and 15 kW, respectively. To run higher-current IGBTs effectively at these frequencies, designers would need larger heatsinks or higher-rated IGBT parts. Notably, the SiC inverter at 16 kHz still outperformed the IGBT inverter at 8 kHz in efficiency.

Conclusion

Replacing silicon IGBTs with silicon carbide power modules can provide up to about 2.6% overall efficiency improvement in a 25 kW, low-voltage industrial three-phase motor drive. Efficiency gains are observed across the load curve and at higher power levels, yielding meaningful energy savings. Reduced passive component count and smaller heatsinks increase power density and enable smaller system size and cost optimizations. Improved thermal margin and lower losses with SiC allow designers to build more compact drives and simplify integration of the inverter and motor.