Overview

As the first mass-produced four-motor drive technology in the Chinese market, Yisifang uses four independently controlled motors to provide precise wheel-by-wheel torque management. This article outlines the origin, control approach, performance characteristics, and safety functions of the system.

Origins and concept

The prototype of Yisifang appeared about 20 years ago on BYD Group's ET concept vehicle. Inspired by a cheetah's ability to precisely control its posture at high speed, the concept uses four independent motors to drive each wheel, giving the vehicle four independently controlled actuation points for improved handling and stability. Yisifang is a powertrain centered on four independently driven motors, and should not be interpreted in the same way as traditional internal combustion powertrains or earlier three-motor configurations. The four-motor independent drive architecture represents a different approach to vehicle propulsion compared with conventional and previous electric powertrains.

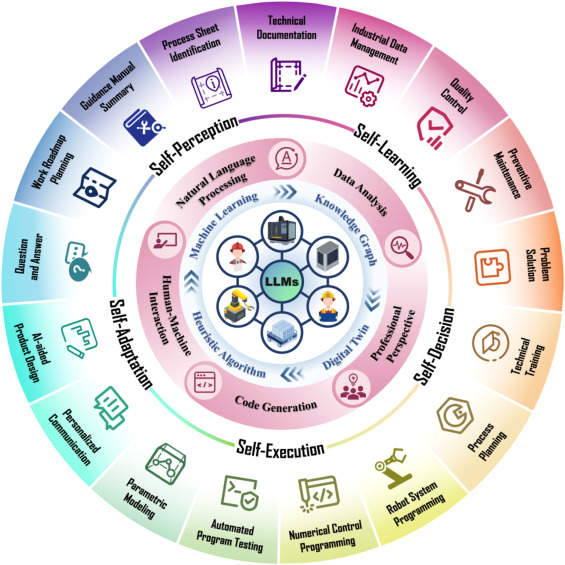

Control architecture and responsiveness

One reason the Yisifang system claims much faster response than traditional four-wheel-drive mechanical systems is that many conventional drivetrains rely on detecting wheel speed differences and then mechanically redistributing torque via transfer cases, which introduces time-consuming steps. The Yisifang architecture removes those mechanical redistribution steps. Wheel-speed sensors and other sensors placed at each wheel measure wheel speed, rolling resistance, and tire pressure. Those signals are processed in millisecond-scale calculations by the central controller, which independently commands each wheel to perform actions such as traction recovery, limited-slip intervention, or braking.

Performance characteristics

At the performance level, the Yisifang platform achieves a motor maximum speed of 20,500 rpm and a vehicle peak power exceeding 1100 hp. Beyond normal commuting, these characteristics become more apparent in off-road and track scenarios. Because each motor can provide independent positive and negative torque, the platform can achieve very short stopping distances and tight turning radii in specific test conditions, for example under controlled scenarios achieving a 100-0 km/h braking distance below 40 m and a turning radius below 12 m. In short, the platform is designed for both stable cruising and agile handling.

Safety and wheel-failure handling

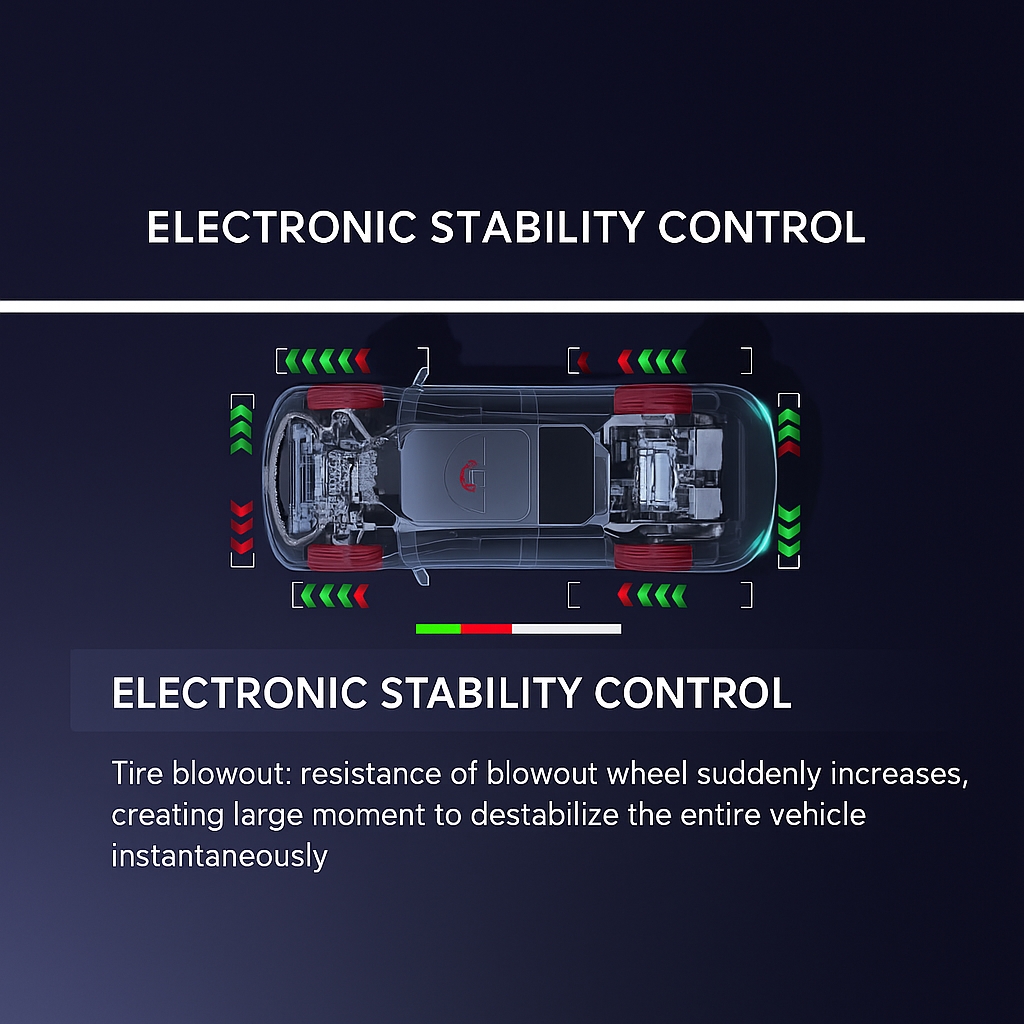

Conventional vehicle stability control systems are constrained by mechanical and sensing bottlenecks, which limit perception speed and control precision. The four-motor drive approach uses high-bandwidth electric drive control to adjust wheel torque independently at millisecond intervals, enabling more precise posture control.

For example, when a single tire experiences a rapid loss of pressure, the vehicle control system can adjust torque on the remaining three wheels at a rate of up to 1000 times per second. By changing drive torque, the system adjusts vehicle posture and center of gravity distribution and applies compensatory interventions to help the driver bring the vehicle to a controlled stop and minimize secondary incidents.

When tire-pressure sensors and wheel-speed sensors detect loss of pressure on a single wheel, the central controller commands precise actions across all wheels. It reduces current output to the intact-side motors to slow the vehicle safely, and it limits current to the deflated wheel. In extreme situations, the system can apply regenerative braking to produce negative torque on the affected wheel to reduce inertial forces. The motor on the wheel opposite the flat increases current output to maintain torque balance with the intact side, counteracting lateral forces caused by inertia, correcting vehicle posture, and enabling a controlled braking trajectory.

Environmental sealing and emergency "float" behavior

Vehicles equipped with the Yisifang system have core systems protected to IP68 levels and feature well-sealed cabins. If water rises above the wheel level and buoyancy reduces tire contact with the ground, the independent vector control of the four motors can provide emergency maneuverability in water. In this mode, the motors can produce thrust and directional control analogous to propellers, allowing the vehicle to maintain controllability and follow a heading in water. This "float mode" relies on the sealed cabin, buoyancy, and precise motor torque control and is not achievable with conventional mechanical drivetrains or typical internal combustion vehicles.