Overview

Displays composed of microscopic inorganic light-emitting diodes (MicroLEDs) have attracted attention because they can offer lower power consumption, higher color saturation, greater brightness, and improved stability compared with organic-LED displays, and they avoid image burn-in. For optimal device performance, LED dies are epitaxially grown on separate wafers and then transferred to the display substrate. The very large number of LEDs required for transfer makes low-cost, high-throughput assembly technologies essential for commercial MicroLED displays.

Key result

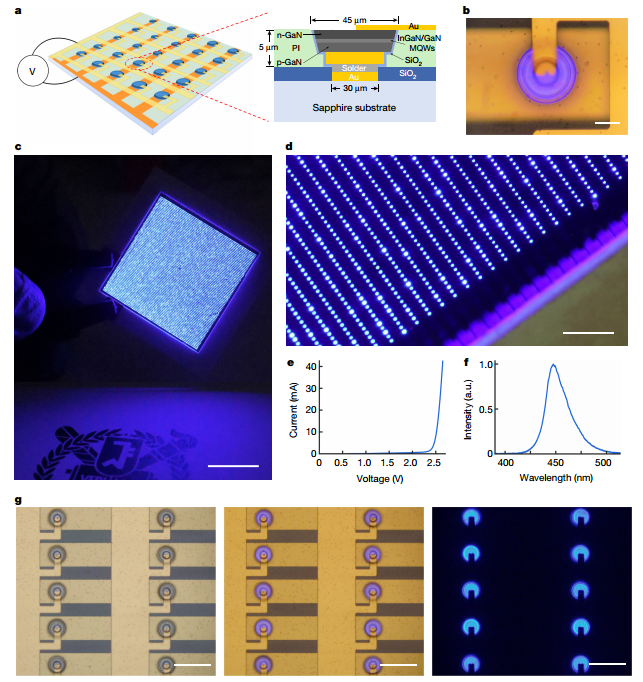

Researchers at Seoul National University led by Sunghoon Kwon demonstrated a MicroLED lighting panel assembled from more than 19,000 disk-shaped GaN dies, each 45 μm in diameter and 5 μm thick. Using a simple stirring-based, surface-tension-driven fluid self-assembly (FSA) method, the array was assembled in 60 seconds with a reported yield of 99.88%. Achieving high-yield FSA for sub-100 μm dies is challenging because inertial forces decrease with die size, reducing impact-driven placement.

Mechanism enabling high yield

The team found that adding a small amount of poloxamer to the assembly solution increased its viscosity and thereby enhanced momentum transfer from the fluid to the dies. This change in fluid dynamics substantially improved assembly yield. The result represents a significant step toward using FSA for low-cost, high-throughput full-color MicroLED manufacturing.

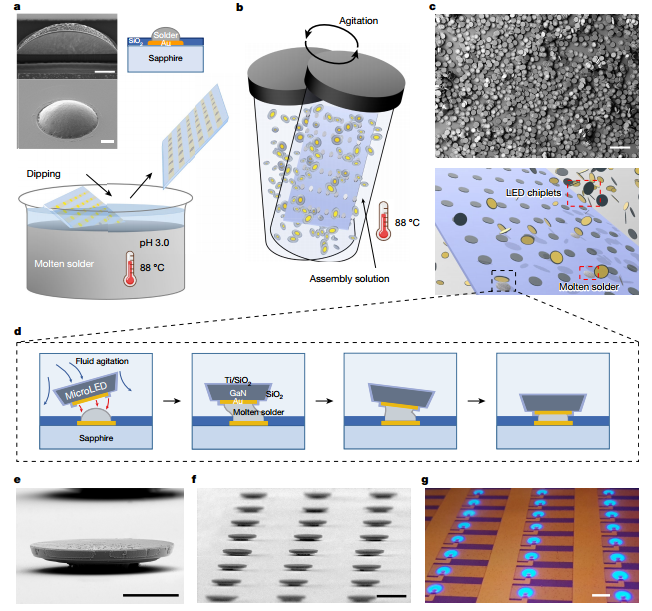

FSA assembly process

The experimental FSA process is simple and stirring-based. Circular gold binding sites were patterned on a sapphire substrate, and molten solder bumps were formed on these sites by dip-soldering. The substrate and GaN MicroLED dies, which have Au on their bottom surfaces, were immersed in the aqueous assembly fluid and manually stirred to cause contact between the solder bumps and the Au layers.

To maximize assembly yield, the liquid was heated to 88°C to keep the solder bumps molten, enabling assembly of a large quantity of dies (approximately 3 million). A small amount of acetic acid was added to the liquid to prevent metal oxide formation on the dies and the solder bumps.

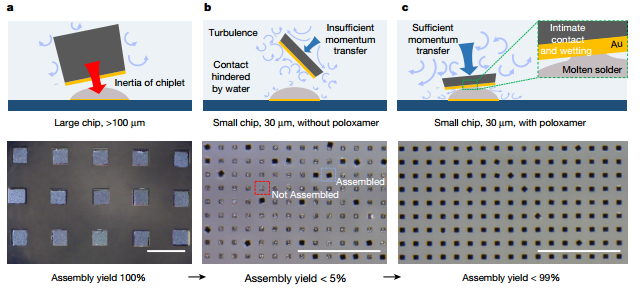

Assembly mechanism differences and yield

Applying the stirring-based FSA to 150 μm cubic silicon dies produced yields exceeding 89%. However, as die size decreased, the assembly results changed markedly. The change in assembled yield arises from a shift in the mechanism that determines die velocity relative to the substrate. As die dimensions shrink, the inertial force that drives dies to impact the substrate decreases. Increasing the viscosity of the assembly solution by adding polymer improved the probability that smaller dies contact binding sites with sufficient force, producing a significant rise in yield. Thus, solution viscosity is an important factor in determining assembly yield.

Panel structure and die design

The paper describes the structure of the FSA-manufactured MicroLED lighting panel. Interconnect top-electrode lines are formed perpendicular to bottom electrode lines. Dies were designed as circular shapes to prevent rotational misalignment between dies and the substrate. By adjusting the diameter of the gold solder pad on the die bottom and the diameter of the circular openings on the substrate, the process prevents multiple dies from occupying a single binding site. The authors provide details of the die fabrication process.

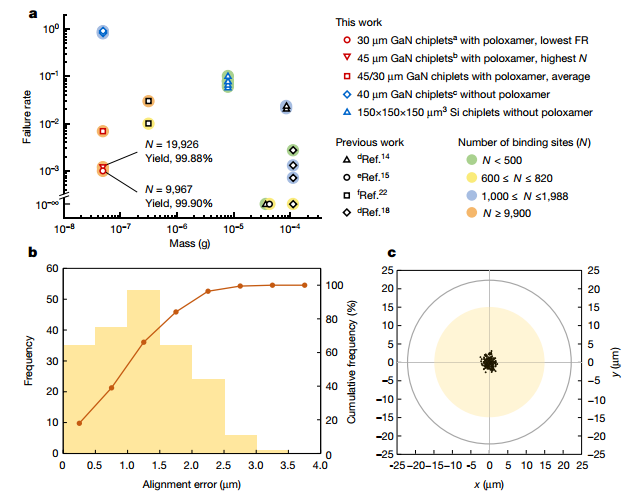

Failure rate versus die mass

The failure-rate (FR) data from the authors' FSA experiments were compared with previously reported stirring-based FSA processes. Except for the data points corresponding to FSA with added poloxamer, the results show an increasing FR trend as die mass decreases. These experiments clarify the unique properties of surface-tension-driven FSA and indicate that the alignment precision of the technique is sufficient for medium and large display applications.