Installation Overview

Construction and installation process

The installation workflow for a display information system is: LED installation team mobilization; on-site confirmation of installation locations; determine final dimensions based on site orientation; conduit and cabling installation; screen panel fabrication; screen installation (coordinated with interior finishes); trial operation of each screen; record of bright and defective pixels; system acceptance; user training for the display system; system handover and commissioning.

Pre-installation Preparations

During installation of the display information system and touch-screen interfaces, each screen must coordinate closely with the client to complete the required conduit and embedded cabling work. Ensure signal pathways do not physically cross or interfere with high-voltage power or HVAC runs. Additionally, ensure that the installed screen will not compromise the aesthetic of the finished interior and that its installation complements the building's overall appearance and information presentation.

Throughout the project, unforeseen coordination issues with other contractors and uncontrollable external factors may occur. When issues arise, coordination should be handled through the client or the client's construction supervisor according to the actual situation.

Key Construction Points and Considerations

Interfaces for large-screen information systems are typically network-standard RJ45 connectors. Large screens should be networked via reserved structured-cabling points; this approach reduces strict conduit requirements, provided the structured cabling is reserved in the vicinity of the LED installation.

Where a large screen uses an internal subnet rather than the building's structured cabling, fiber optic transmission can be used for signal transport. After screen installation, optical-to-electrical conversion at the screen terminus will implement the data flow.

Large-screen systems require on-site mains power. During conduit and cable routing preparation, requirements for the mains supply must be coordinated with the electrical contractor to avoid cross-discipline gaps that lead to installation issues.

Conduit and Cabling

For long conduit runs and routes with many bends, pre-thread steel wire to facilitate pulling cables later. Ensure proper grounding between conduits, junction boxes, and enclosures; use steel bridging of at least 6 mm diameter for threaded connections to ensure a good earth connection. Separate conduits for different systems, voltage levels, and current categories. Before pulling cable, use compressed air to clear water and debris from conduits and apply a small amount of talcum powder to reduce friction. Remove any burrs at conduit ends to avoid damaging conductor insulation during pulling. Use a wire-dispensing rack when paying out cable to prevent tangling; junctions should be inside junction boxes. Fit conduit ends with bushings where required. After conductor terminations, solder joints and wrap them firmly with insulating tape.

Equipment Installation

Related Notes

Power distribution: The display system uses 220 V AC power. Total power consumption equals the sum of each subsystem's consumption.

Goods inspection and unpacking: Determine delivered item counts based on the contracted screen area. On receipt, verify quantity against shipping documents, then unpack and inspect items against the packing list.

Power distribution installation: The display uses AC power. Typical wiring follows a three-phase five-wire method for larger installations.

Unit module (cabinet) installation steps:

- Verify the rigidity and secure fastening of the prepared frame and supports.

- Install display modules starting from the lowest row, proceeding layer by layer upward.

- Connect inter-module cabling.

- Connect the power supply lines.

Driver installation: Device drivers are provided for supported operating systems. Install the drivers using the standard driver-installation procedure.

Ground connection: Connect all grounding points to the building earth electrode.

System connection checks:

- Observe connector polarity and orientation during insertion.

- Ensure all connectors are fully engaged and not loose.

- Confirm all earth/ground conductors are securely connected.

System Commissioning

Module-level quality control is typically completed prior to shipment, so on-site commissioning focuses on luminance calibration and networked display control testing. Brightness adjustment is a straightforward visual procedure carried out on-site. Software network control and screen mapping are the commissioning priorities as described below.

Multimedia content editing and calibration:

- Text: Text is the most common content type. Prepare and edit text, perform localization if required, and configure fonts, sizes, colors, alignment, and special effects within the authoring software. Then verify text rendering against the installed screen.

- Graphics: Graphics convey complex information and support attractive UI design. In authoring tools, verify image scaling, cropping, and tiling behavior.

Display monitoring and control testing: Verify that the host control computer can manage display content and playback modes, and that the control software provides real-time status monitoring.

Network testing: Verify that the control computers form a local area network for resource sharing. Confirm that standard network interfaces can connect and that the networked publishing software can distribute content. After networking, each terminal should respond promptly to control commands; produce a commissioning acceptance report.

Common Commissioning Faults and Solutions

1) Entire screen not lighting: Verify the host computer is functioning and that control-system cabling to the screen is correctly connected and making good contact. Confirm the control system is powered and its outputs are connected in the correct order. If those checks pass, inspect the screen's power supply and verify environmental temperature and humidity are within product specifications.

2) Image instability or horizontal wobble: This typically indicates a potential difference between the control system digital ground and the screen digital ground. Check grounding connections between the control-system output ground and the input ground of the first module.

3) Image position incorrect or missing (image mapped outside the display area): Check and adjust frame offset and mapping settings to align displayed content with the screen.

4) Static on the screen: Immediately power down the screen and verify the power-ground conductor continuity. Measure resistance between screen metal parts and earth with a multimeter to confirm proper chassis grounding.

5) Missing color channels: Possible causes include power supply protection trips or output faults for that channel; color brightness set to minimum; loose data cable connections; or failure in the corresponding data channel.

6) Background tint on the image: External interference exceeds system tolerance. Refresh the displayed content.

7) Localized module failure or dark modules: Open the rear access, verify the power supply feeding the affected modules, and replace any defective power supply units. Re-seat or replace loose or faulty data cables.

Trial Operation and Testing

Initial Power-up and Test

After system assembly, verify all signal and data cabling connections, then power the screen. Use a dedicated test device to check the display in sections, for example every 16 rows. After full-screen verification, power down all equipment, restore normal connections, remove the test device, and restart the system according to the correct power-up sequence for control computers and panels.

Operational Run

Unit modules undergo factory burn-in, thermal, and vibration testing. Once assembled and commissioned, the system is expected to run reliably for extended periods. Normal operating environment conditions:

| AC operating voltage | 220 V 50/60 Hz |

| Operating temperature | Low -20°C; High +60°C |

| Relative humidity | 10% - 95% |

Installation Plan

After coordination with the client, proceed to the site at the agreed time to begin formal installation. The specific construction plan is as follows.

Site survey, design drawings, and wiring diagrams

Technical staff perform an on-site survey to:

- Confirm screen installation location and surroundings

- Confirm control room location and environment

- Measure actual signal and data transmission distances

- Design signal cable routing

- Produce construction drawings, wiring diagrams, and power distribution diagrams

System wiring and power distribution

Install communication cables according to the design drawings prepared from the site survey:

- Prepare and clear cable routes, including necessary excavation or drilling

- Install conduits and pull-in cables

- Install cable accessories and connectors

Screen frame fabrication

Fabricate and install structural frames per design drawings:

- Manufacture outer frames to required tolerances

- Install outer frames

- Install screen-facing decorative materials

- Route internal power wiring

Screen installation

After frame installation:

- Install and secure display cabinets to ensure accurate positioning and mechanical strength

- Electrical technicians complete cabinet interconnections and signal cabling

- Install distribution boxes and connect power lines

- Establish control networks

Schedule and Project Management

An electronic display project is a systems-level undertaking involving many stakeholders. The project should proceed according to plan and stages under unified project management, following quality control practices to ensure each phase is controlled. Typically, the system can be delivered for use approximately 30 days after contract signing, subject to mutual agreement on special circumstances.

Estimated total on-site construction time: within 15 days.

Project Phases and Responsibilities

1. Design confirmation: Engage with client stakeholders, validate and revise the design until finalized, document the approved plan as a contract attachment.

2. Pre-construction preparation: System engineering leads site surveys and defines communication and power routing plans and civil coordination items, with client written confirmation.

3. Material procurement: Procure printed circuit boards, modules, components, communication cables, main control systems, and fabricate structural parts.

4. Production and workshop testing: Manufacture and screen modules, perform selection and debugging. After quality control acceptance, perform full-screen assembly, system integration, and simulated environment testing.

5. Burn-in and inspection: After full assembly, conduct 72-hour full-load burn-in per relevant industry production standards. Perform comprehensive tests and rectify any quality issues, followed by re-testing.

6. Installation and on-site commissioning: Packing and delivery, site cabling, full-screen installation, and system-level debugging.

7. Trial operation: Run the system per contract and standards; rectify issues and repeat trial operation until requirements are met. Invite the client to participate.

8. User training: Train client personnel on software operation and basic hardware maintenance. Training includes:

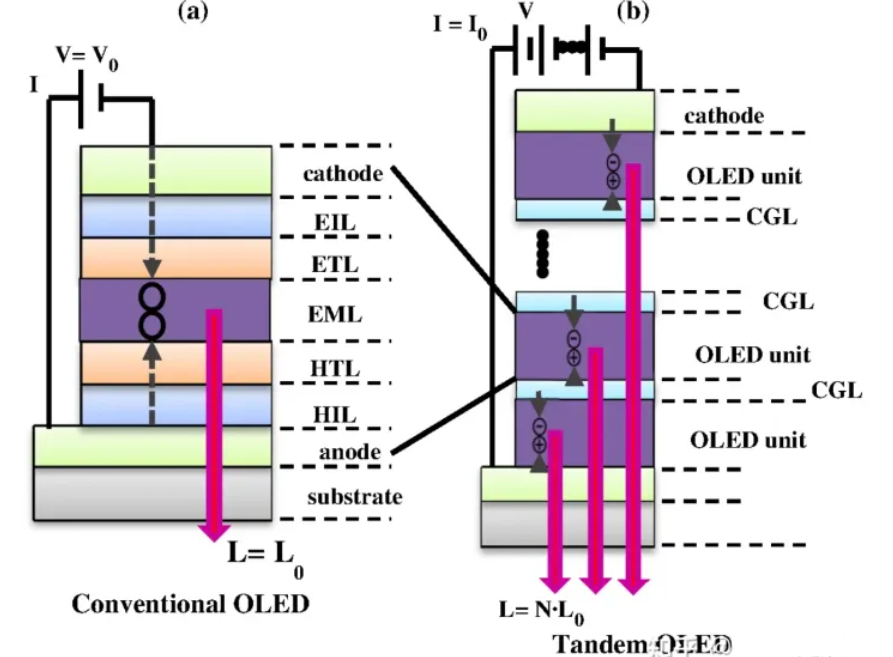

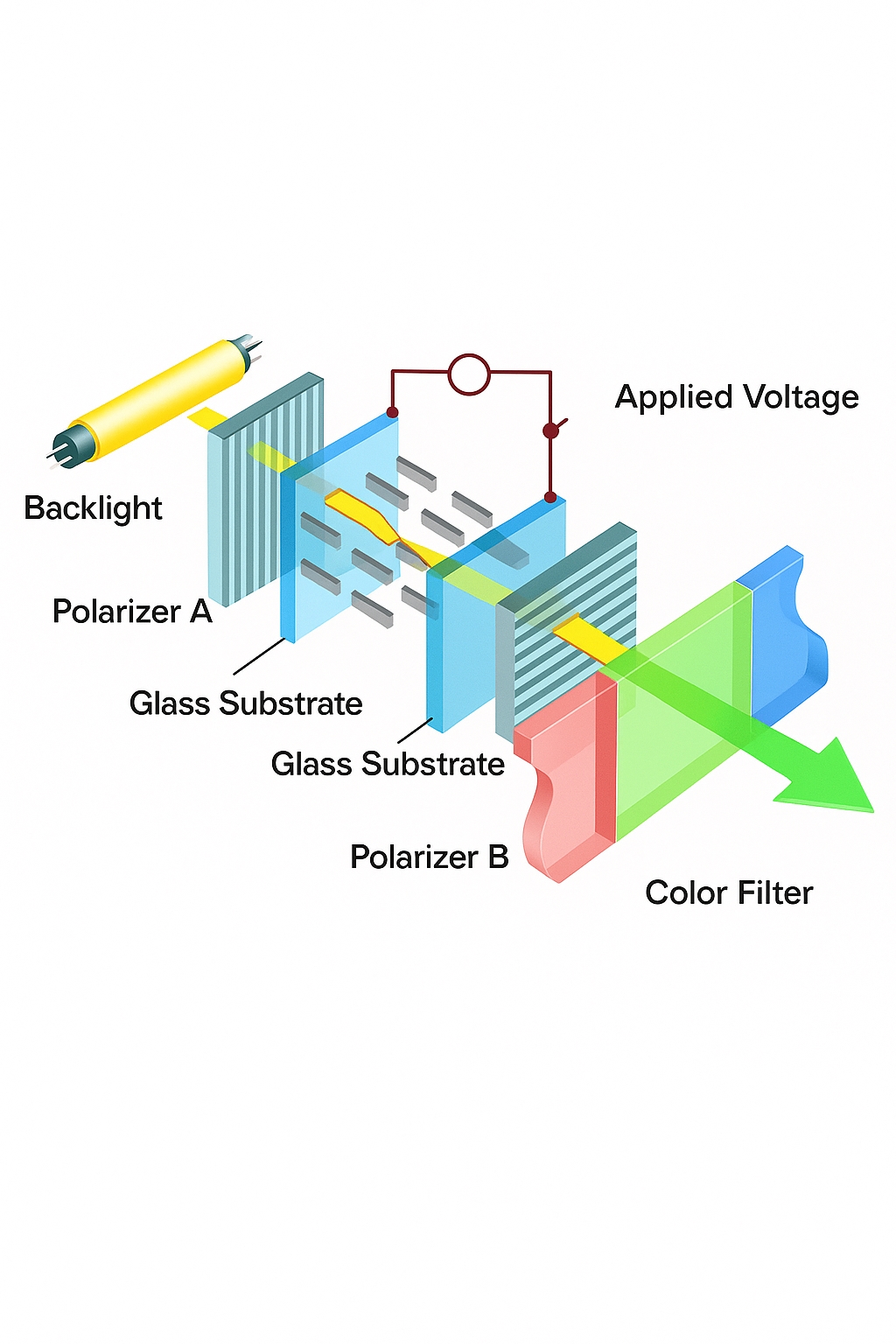

- Basic working principles of the display

- System operation and administration

- Daily maintenance and safety precautions

- Software installation

- Routine content maintenance

- Basic software and hardware troubleshooting

Provide operation and maintenance manuals before training. Client designates trainees and training schedule is agreed by both parties. Training completion should be acknowledged in writing by the client.

Acceptance

Final acceptance marks project completion. Both parties inspect the system against standards and contract requirements, hand over documentation, and complete related transfer items.

Additional Notes

Acceptance and Testing

Comprehensive acceptance of an LED display system covers components, the assembled product, and installation quality. Recommended acceptance steps during the project:

1. Module and LED acceptance: Verify key material performance such as brightness, viewing angle, and grayscale level. Grayscale affects image smoothness and color richness. Specialized display controller ASICs can manage high-precision grayscale control to improve perceived image quality.

2. Application software functionality acceptance: Verify all required system functions are implemented, operator performance is satisfactory, and interfaces meet specifications.

3. Simulated system acceptance: Factory-based acceptance on a simulated system to verify product quality, workmanship, and appearance of display units, control components, power cabinets, and frames. Provide factory test criteria as reference for acceptance.

4. Frame installation quality acceptance: On-site inspection of frame installation, overall appearance, flatness, structural rationality, and maintainability.

5. Final system acceptance: Comprehensive acceptance after installation and commissioning to ensure all contract requirements are met.

Training

Training aims to qualify system operators to run the system and handle common faults. Training occurs in two stages and covers approximately three trainees:

1. Basic training at the manufacturer's training center: computer fundamentals, display working principles, content authoring and playback software, monitoring software, and maintenance and safety practices.

2. On-site training: focus on system operation, installation and testing procedures, grounding and lightning protection, daily maintenance, basic troubleshooting, equipment maintenance, and distribution of training materials. Operators should participate in installation and commissioning.

After-sales Service

Provide timely technical support, on-site maintenance, scheduled maintenance, spare parts availability, and a professional service team. During the warranty period, provide on-site support regardless of fault magnitude. Dispatch experienced technicians for design, installation, debugging, diagnosis, and repair.

Warranty: Free repair or replacement for defects caused by non-human factors during the warranty period. After warranty, service provided at cost.

Response and hotline: Upon notification, field engineers should aim to reach the site within the same day when feasible; emergency response may require project leadership on-site. Spare parts replaced during repair will be repaired or replaced within two weeks and maintained in a ready state. Staff can typically reach the site within six hours of a service call.

Spare parts supply: Maintain stock of spare parts to minimize downtime; ensure consumables and common spare parts are available within seven days.

Scheduled maintenance: Implement a periodic maintenance program in addition to reactive support.

Construction Quality Measures

Quality Management System

Under project management leadership, define quality responsibilities for all personnel:

- Project manager is the primary quality-responsible person for the project.

- Lead engineer assists the project manager and conducts site oversight, ensuring work adheres to drawings and standards; any changes must be approved through formal procedures.

- Team leaders are responsible for quality within their teams and must maintain traceable records.

- Quality inspectors must follow acceptance criteria and inspection procedures, document results, and escalate issues that cannot be resolved locally.

- Operators must perform self-inspection and peer inspection; nonconforming items must be repaired or scrapped and may not be concealed.

Quality Assurance Measures

Key measures include:

- Thorough review and familiarization with design drawings and technical documentation before work begins.

- Pre-construction briefings by the lead engineer covering new processes, devices, materials, and potential issues and preventative measures.

- Careful review of incoming materials and documentation.

- Establish QC teams to evaluate construction quality and correct problems promptly.

- Quality department to perform random audits and follow-up corrective and preventive actions.

- Quality personnel to track and stop nonconforming work from progressing to the next stage.

- Key trades such as electricians must be certified. Assign clear responsibilities to increase accountability.

- Measurement and test equipment must be calibrated and maintained with valid certificates; uncalibrated instruments must not be used.

- Comply with client quality inspection and acceptance procedures and operate within the established quality-management system.

Implement a three-tier inspection regime: self-inspection by the trade team, specialized inspector check, and lead engineer recheck. Record inspection results and mark the inspection status.

Common Quality Issues and Prevention

1) Verify power wiring correctness for screens and signage, including conductor markings and polarity. Use a multimeter to check for shorts or open circuits. Check module seams for water ingress that could affect connections. Power sequence tests should ensure brightness and chromaticity consistency.

2) For conduit routing, maintain adequate bend radii, minimize bends, ensure exposed conduit is level and plumb, space support points evenly, remove debris and water before pulling wire, and fit conduit bushings to prevent conductor insulation damage.

3) Do not route conductors of different voltage levels or current categories in the same conduit or cable trough slot.

4) Avoid splices or knots inside conduits; joints should be made within junction boxes and use terminal blocks where required.

5) Seal conduit ends and connections in dusty or humid environments.

6) At building movement joints, implement compensation for conductor runs crossing expansion or seismic joints; secure both sides and leave slack for movement.

Safety and Site Conduct

Safety Measures

Establish a safety assurance system led by the project manager with clear responsibilities. Implement and enforce safety management procedures, educate all incoming personnel on safety responsibilities, and require certified training for special trades. Conduct regular safety inspections and maintain written safety handovers. Follow a three-not-leave principle for incident handling: do not close investigation until causes, responsibilities, and preventive measures are determined. Report major incidents to authorities as required.

On-site Safety Practices

- Provide necessary personal protective equipment: protective clothing, gloves, helmets, insulating gloves, welding protection, etc.

- Require certified operators for special operations, with valid documentation.

- Equip sites at risk of fire with portable fire extinguishers and ensure they are serviceable.

- Use insulated wiring for temporary power; ensure feeder capacity exceeds equipment load and wires are supported and protected to avoid damage or exposure.

- Only certified electricians may perform permanent electrical installations, with dedicated personnel for inspection and maintenance.

- Temporary distribution boxes must be complete and include residual-current protection devices with operating currents not exceeding 30 A. Keep enclosure doors closed during operation and route conductors through proper entries.

- No alcohol consumption on-site. Maintain professional conduct and avoid horseplay.

- For hot work, obtain permits, use protective equipment, and ensure no flammable materials are nearby.

- Use fall protection for pole or elevated work, secure tools, and prohibit passing objects by throwing.

- Designate responsible operators for equipment and enforce safety operation rules.

- During lifting, assign a single qualified person to direct operations; prohibit standing beneath suspended loads.

Civil Conduct Measures

Comply with applicable local regulations for construction site management. Maintain clean transport routes and work areas, remove construction debris daily and dispose at client-approved locations. Maintain civil behavior among staff, minimize disturbance to the public, and implement barriers and signage for night work to prevent pedestrian access to hazardous zones.

Equipment Transportation

Due to site constraints and dispersed installation locations, coordinate with site management to designate safe staging areas for material storage and protection. Use vehicle transport for construction platforms and equipment and protect elevator interiors and passageways during handling.

Handover and Commissioning Guarantees

Maintain sufficient labor and coordination to meet the project schedule, operating multiple shifts if required. The project manager oversees resources, and the lead engineer provides technical guidance to prevent rework. Plan and control material supply to eliminate work stoppages due to missing or poor-quality materials. Maintain a stable, skilled workforce to meet milestone targets and prioritize recovery plans for any delayed work packages. Focus on resolving bottlenecks and ensure readiness for client inspections and final acceptance.