Introduction

A pressure sensor detects or monitors gas or liquid pressure and converts that information into an electrical signal suitable for monitoring or controlling the measured force. The operating principle depends on the specific sensing technology. This article summarizes pressure sensor technologies and describes characteristic features of pressure sensors offered by CUI Devices.

Definitions and Key Terms

Pressure is the magnitude of force applied per unit area of a surface, described by P = F/A. The SI unit of pressure is the pascal (Pa), defined as one newton per square meter. Pressure can also be viewed as the force required to prevent a fluid from expanding.

A sensor is a device that detects or measures a physical quantity (stress, temperature, displacement, pressure) and typically converts it into an electrical signal.

The terms pressure sensor, pressure transducer, and pressure transmitter are often used interchangeably because they perform the same basic function. The difference lies mainly in the output signal. A pressure sensor detects stress and converts it into an output related to the applied pressure. A pressure transducer typically provides a continuous voltage output (V), while a pressure transmitter provides a current output in milliamps (mA).

Pressure sensors are used under many names, including pressure transducer, pressure transmitter, pressure sender, pressure indicator, manometer, and pressure gauge. In addition to direct pressure measurement, pressure sensors can be used indirectly to determine flow, velocity, liquid level, or altitude.

Some common terms to understand when working with pressure measurement:

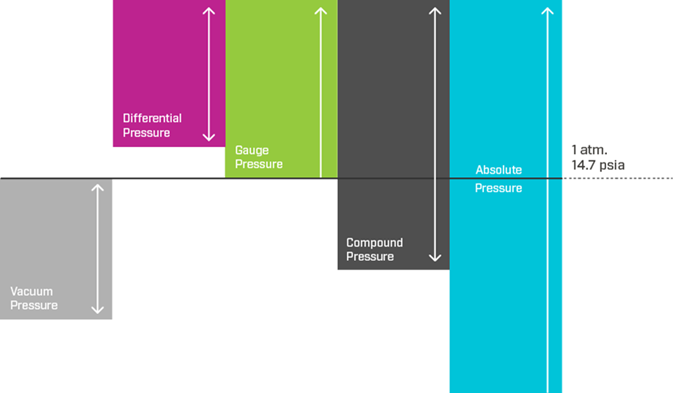

- Gauge pressure: pressure measured relative to local atmospheric or ambient pressure. The indicated value will be above or below the local atmospheric pressure.

- Absolute pressure: pressure measured relative to a vacuum reference. Absolute pressure measurements are consistent regardless of location.

- Differential pressure: the pressure difference between two points in a system, commonly used to measure flow in pipes.

- Vacuum pressure: negative pressure relative to ambient or local atmospheric pressure.

- Compound pressure: includes both positive and negative pressure or vacuum, effectively a combination of gauge and vacuum measurements.

Technologies Used to Measure Pressure

Several sensing technologies are used to detect pressure. The variety has grown, particularly with the availability of semiconductor-based sensors. Major pressure measurement technologies include:

- Potentiometric: uses a resistive element connected to a Bourdon tube or similar mechanism with a sliding arm. As pressure changes, the sliding arm moves and the resistive element produces a proportional signal.

- Strain gauge: converts pressure-induced mechanical strain into a change in electrical resistance, which is measured to determine the applied force.

- Capacitive: detects changes in capacitance caused by diaphragm deflection between capacitor plates under pressure.

- Inductive: senses small diaphragm deflections coupled to a magnetic core, causing linear movement that alters induced current and produces an electrical output.

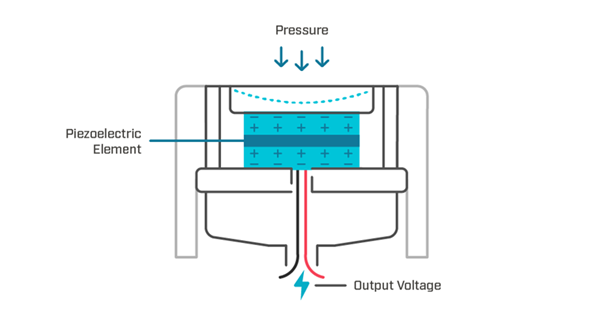

- Piezoelectric: detects compression of piezoelectric crystals or ceramics; mechanical deformation generates a proportional electrical charge.

- Resonant: monitors the resonant frequency of a vibrating element inside a diaphragm, converting frequency shifts into a pressure reading.

- Optical: uses light attenuation or interruption as pressure changes; fiber-optic sensors can operate on a similar principle.

Pressure sensors can also be classified by application type and construction:

- Vacuum sensors: measure pressures below atmospheric pressure, often using piezoelectric or volume-based techniques.

- Sealed gauge: reference is sealed at atmospheric pressure at time of manufacture.

- Vented gauge: measures pressure relative to ambient atmospheric pressure.

- Diaphragm: employs a thin, flexible circular metal plate that deforms under pressure.

- Strain gauge type: senses length changes caused by external force and converts them into resistance changes.

- Solid-state: contains no moving parts and uses semiconductor devices such as FETs for pressure sensing.

- Thin-film: uses elongated thin films composed of resistive elements; resistance changes with deformation due to pressure.

Design Considerations When Selecting a Pressure Sensor

When selecting a pressure sensor for a design, consider several system parameters to determine the most suitable device:

- Sensor type: gauge, sealed gauge, absolute, strain gauge, piezoelectric, etc.

- Operating pressure range: the range over which the device must accurately sense pressure per the manufacturer specifications.

- Operating temperature range: the temperature bounds within which the device must perform reliably.

- Proof pressure: the maximum pressure the sensor can withstand without permanent damage.

- Output type: analog or digital output formats appropriate for the system.

- Output level: the output signal range, typically expressed in millivolts or volts DC.

- Accuracy and drift: the required measurement accuracy and how the sensor may drift over time relative to calibration specifications.

- Resolution: the smallest pressure change the sensor can detect.

- Supply voltage: the voltage required to operate the sensor.

- Environmental conditions: exposure to temperature extremes, humidity, liquids, radiation, and the physical distance between sensor and receiving electronics.

There is no single universally accepted standard for pressure sensor accuracy. Some regional and industry standards relevant to sensor accuracy and usage include IEC 60770 and DIN 16086; ASTM F2070 covers general requirements for pressure sensors in certain applications. Application-specific technical standards guide proper use in areas such as medical devices or automotive systems, for example SAE J1347 for engine-related measurements and IEEE 1451.1 through 1451.7 for industrial sensor interoperability.

Available Pressure Sensor Options

Accurate and reliable fluid and gas pressure sensing is critical across many industries, from process control to medical devices. Modern pressure sensors vary in type, technology, size, output, and accuracy. Identifying the required specifications for a given application enables selection of an appropriate sensor.

CUI Devices produces a line of piezoresistive-based pressure sensors available in absolute, gauge, and sealed gauge configurations with pressure ranges from 0 kPa to 100 MPa. These products include temperature compensation, stainless steel housings, and O-ring seals. Output options include analog or I2C digital interfaces. Excitation ratings are offered at 3.3 V, 5 V, 10 V, or 1.5 mA, with terminal options including 3-, 4-, 5-, or 6-pin connectors.

Conclusion

Pressure sensors play a crucial role in industrial automation and other fields by providing the pressure data needed to maintain safety and product quality. Selecting the right sensor requires careful consideration of measurement range, accuracy, environmental conditions, output type, and mechanical robustness. A variety of sensor technologies and product configurations are available to meet diverse application requirements.