Abstract

High-reflectivity surfaces such as glass, mirrors, and water commonly appear in depth sensing and 3D imaging. They often cause severe depth errors, for example ghost reflections and virtual images that lead to incorrect depth measurements. Mainstream 3D cameras, including conventional structured-light cameras, stereo cameras, and time-of-flight (ToF) cameras, have clear limitations in these scenarios. To address these issues, a team at Bosheng Optoelectronics designed a polarization structured-light 3D camera. On the transmitter (TX) side, high-contrast grating (HCG) vertical-cavity surface-emitting lasers (VCSELs) provide structured light with strong polarization selectivity. On the receiver (RX) side, an infrared CMOS camera with a polarizer selectively receives the signal. Various tests show that this polarization structured-light camera can accurately capture depths in scenes containing reflective surfaces under different imaging conditions.

Background

Detecting reflective surfaces reliably has been a longstanding technical challenge for detectors. Many techniques have been applied, including polarization imaging, fusion of active emitters with sonar, and deep learning methods, but most remain insufficiently robust in real-world scenes due to reflections and multipath noise.

Polarization imaging analyzes multiple images captured at different polarization angles to infer 3D shape. Its first use to determine reflective surface 3D orientation dates to the 1990s. Since then, polarization imaging has been applied to reconstruct shapes of transparent and specular objects. Combined with various depth sensors, it can improve reconstruction. However, polarization imaging requires multiple polarization captures to estimate relative depth and depends on prior knowledge of object refractive indices, limiting its general applicability. Image-based methods are also prone to errors from reflected ghost images and cannot reliably measure the depth of reflective surfaces.

Active ranging and imaging methods, such as lidar and structured-light cameras, are widely used in depth sensing. To handle reflective surfaces, some lidar approaches analyze the distribution of returned intensity to identify glass regions. Lidar combined with sonar or polarization imaging has also been applied to robot navigation in glass environments. These methods often require scanning multiple angles to determine reflective surface depth and are not well suited for general 3D imaging of reflective surfaces. For structured-light systems, fusion with sonar can produce depth maps of glass scenes, but sonar data are sparse and narrow in angular coverage, requiring multiple scans and increasing system cost, size, and complexity.

Deep learning approaches have recently addressed reflective-surface detection by training networks on large datasets of reflective-surface images to identify such regions in new inputs. These methods can still misclassify empty framed regions or boundaries as reflective surfaces. Therefore, a robust method for 3D imaging in reflective-surface environments remains necessary.

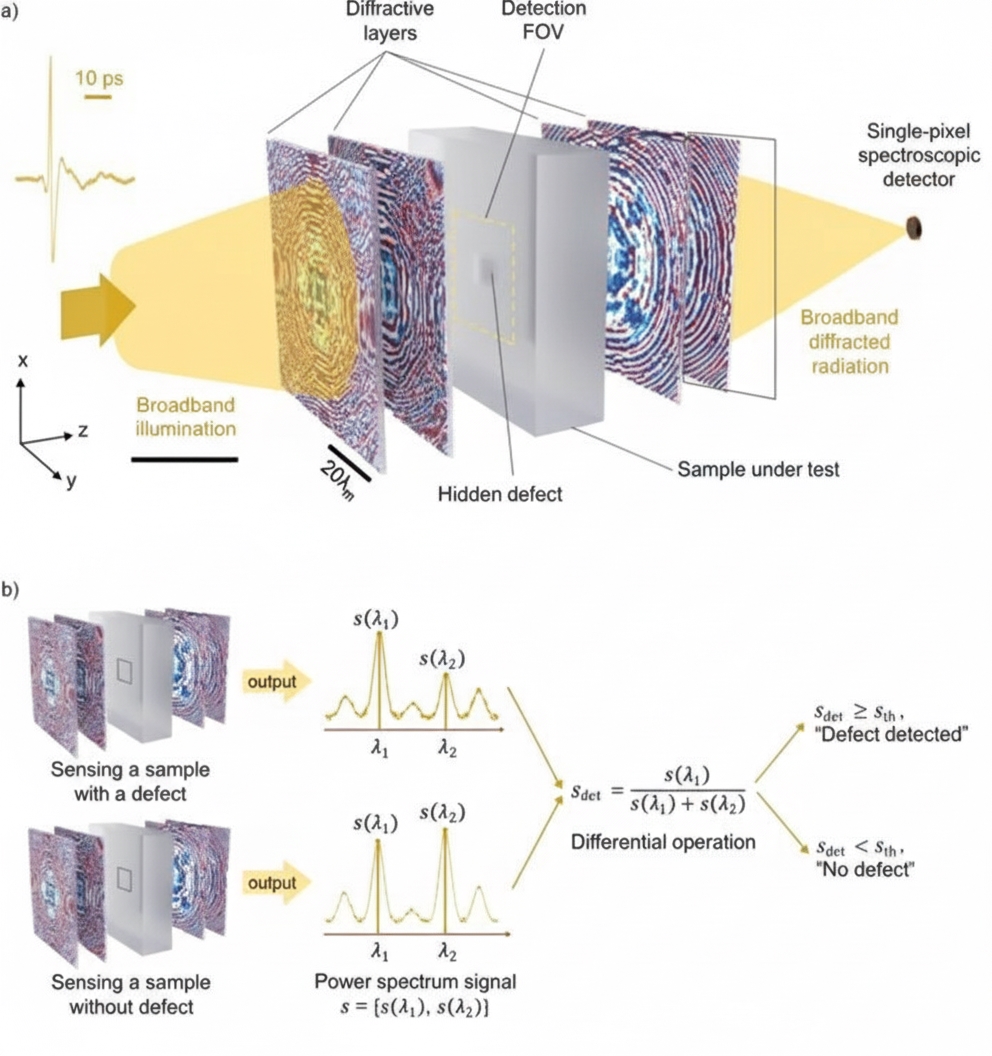

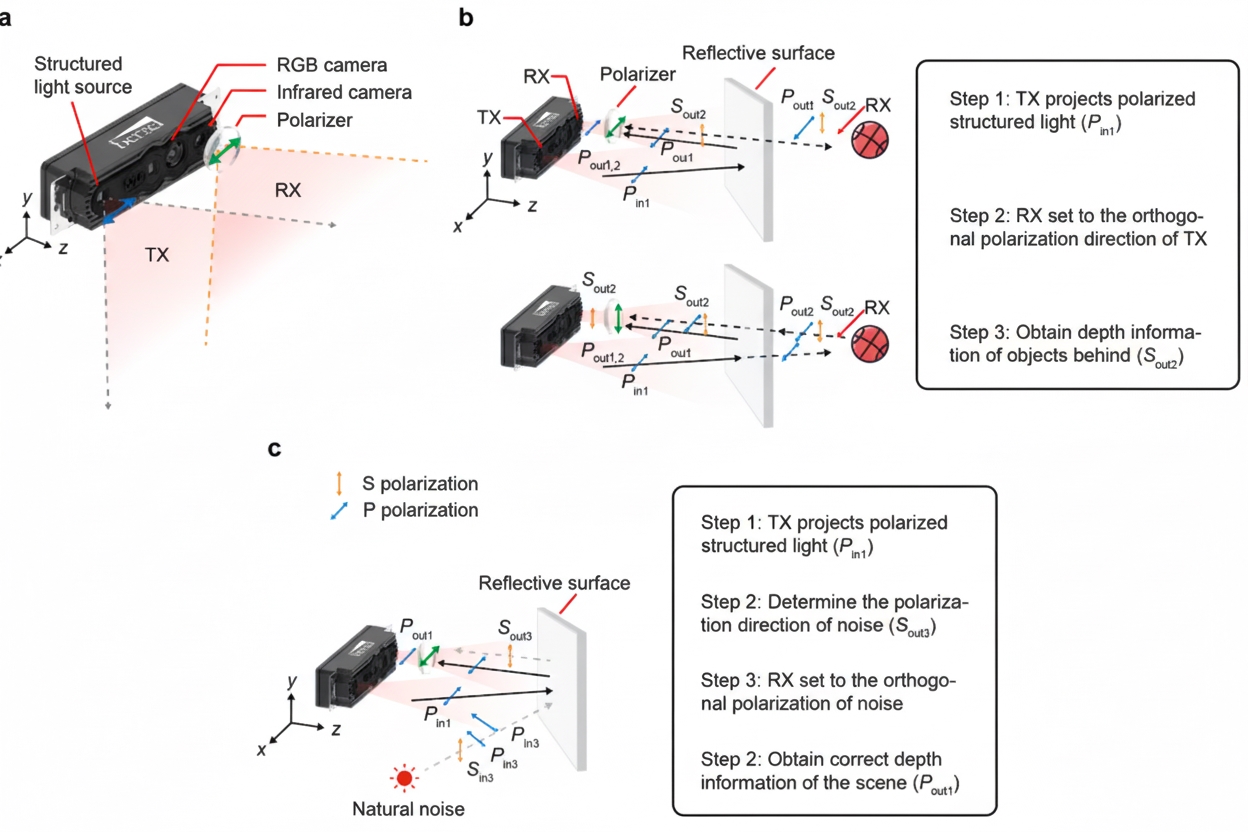

Polarization Structured-Light System

According to Mems Consulting, the Bosheng Optoelectronics team developed a polarization structured-light (PSL) 3D camera that incorporates polarization features on both transmitter (TX) and receiver (RX) sides (Figure 1). The TX uses HCG-VCSELs designed to provide structured light with a strong polarization extinction ratio. The RX uses a polarization-selective CMOS camera to receive signals selectively. Based on Fresnel theory, specular reflection preserves the polarization of the incident light, whereas diffuse reflection does not present a consistent polarization even under strongly polarized incidence. Using a polarization-selective CMOS camera allows differentiation between reflective surfaces and other objects, and by selecting the polarization direction, the system can obtain depth information for either the reflective surface or objects behind it (Figure 1b). Furthermore, by configuring TX and RX polarizations, reflections from multipath noise can be filtered out to obtain a clear scene depth (Figure 1c). The paper presents three experiments demonstrating how the PSL 3D camera enables both seeing and seeing-through reflective surfaces.

Figure 1. Polarization structured-light 3D sensor principle

See-Through Reflective Surface Results

First, the paper demonstrates the PSL 3D camera's ability to see through a glass door in an indoor scene. As shown in Figure 2, the PSL 3D camera faces a glass door at distances from 0.4 m to 1.2 m. Behind the glass door are a cabinet and a basketball, fixed at 0.5 m behind the glass. The TX projects polarized structured light onto the scene, and the RX receives the reflected structured light that contains depth information for both the glass door and the objects behind it. The glass door reflection preserves the TX polarization, while the cabinet and basketball produce diffuse reflections with mixed polarization. When the RX polarization is set parallel to the TX polarization (0° example), depth reconstruction includes the glass door, the cabinet, and the basketball. When the RX is rotated to the orthogonal polarization (90° example), the glass contribution is filtered out, leaving the cabinet and basketball depth information. The same see-through and see-through-filtering functions were observed at 0.8 m and 1.2 m distances.

Anti-Reflection-Noise Imaging Results

Next, the paper presents PSL 3D camera performance in reducing reflection noise in outdoor and indoor scenes (Figure 2). In an outdoor glass scenario (Figure 2a), strong specular reflections from ambient light produce significant reflection noise that prevents a stereo camera from obtaining a usable depth map. This noise has a large S-polarized component. By configuring both TX and RX to P polarization, the system can suppress this noise and increase the signal-to-noise ratio. Under this P-polarization configuration, the PSL 3D camera can clearly measure the full scene depth (Figure 2c).

Figure 2. Anti-reflection noise imaging experiment results

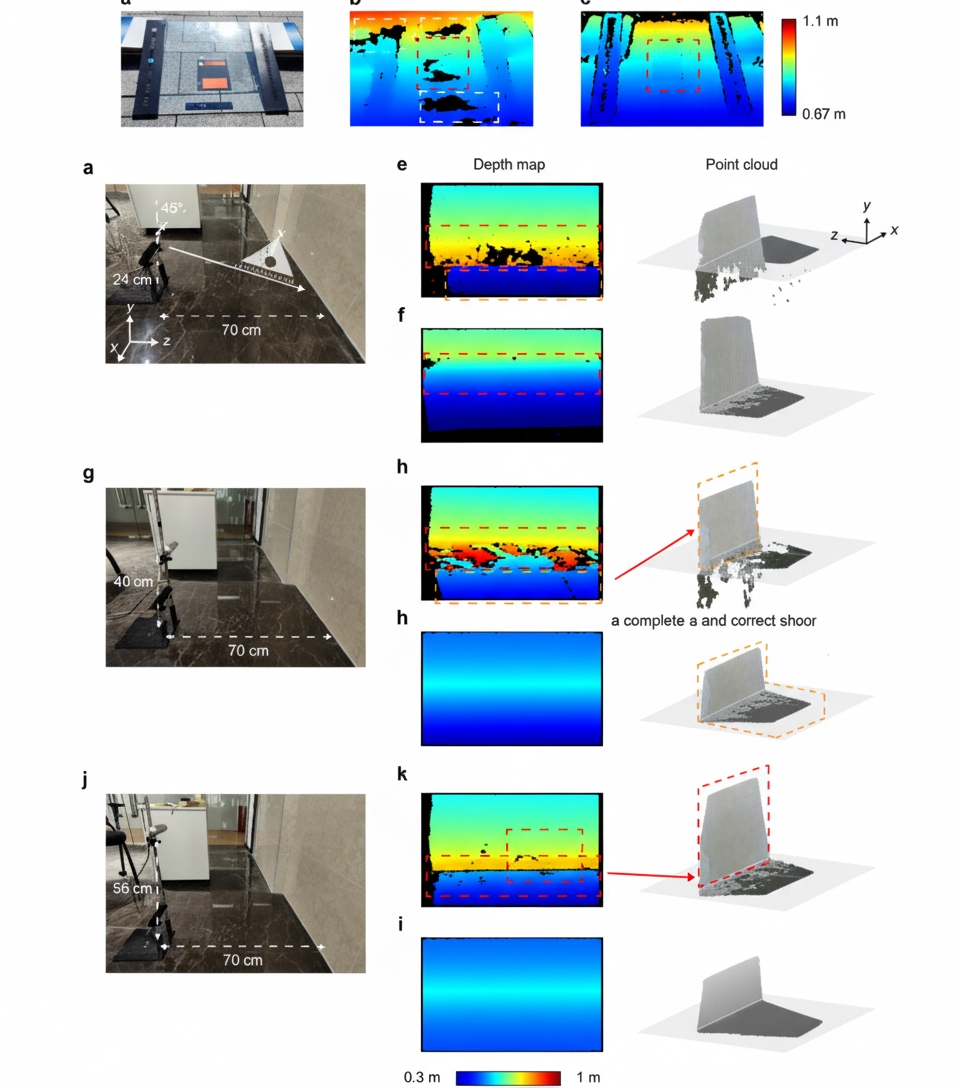

For an indoor corner scenario common in service-robot applications, the paper compares PSL 3D and conventional stereo 3D cameras at three heights: 0.24 m, 0.4 m, and 0.56 m. Stereo cameras produce incorrect depth estimates in these cases due to multipath noise (Figures 3e, 3h, 3k). By setting both TX and RX to P polarization, the PSL 3D camera achieves complete and correct corner depth maps and point clouds (Figures 3f, 3i, 3l).

Reflection Completion Results

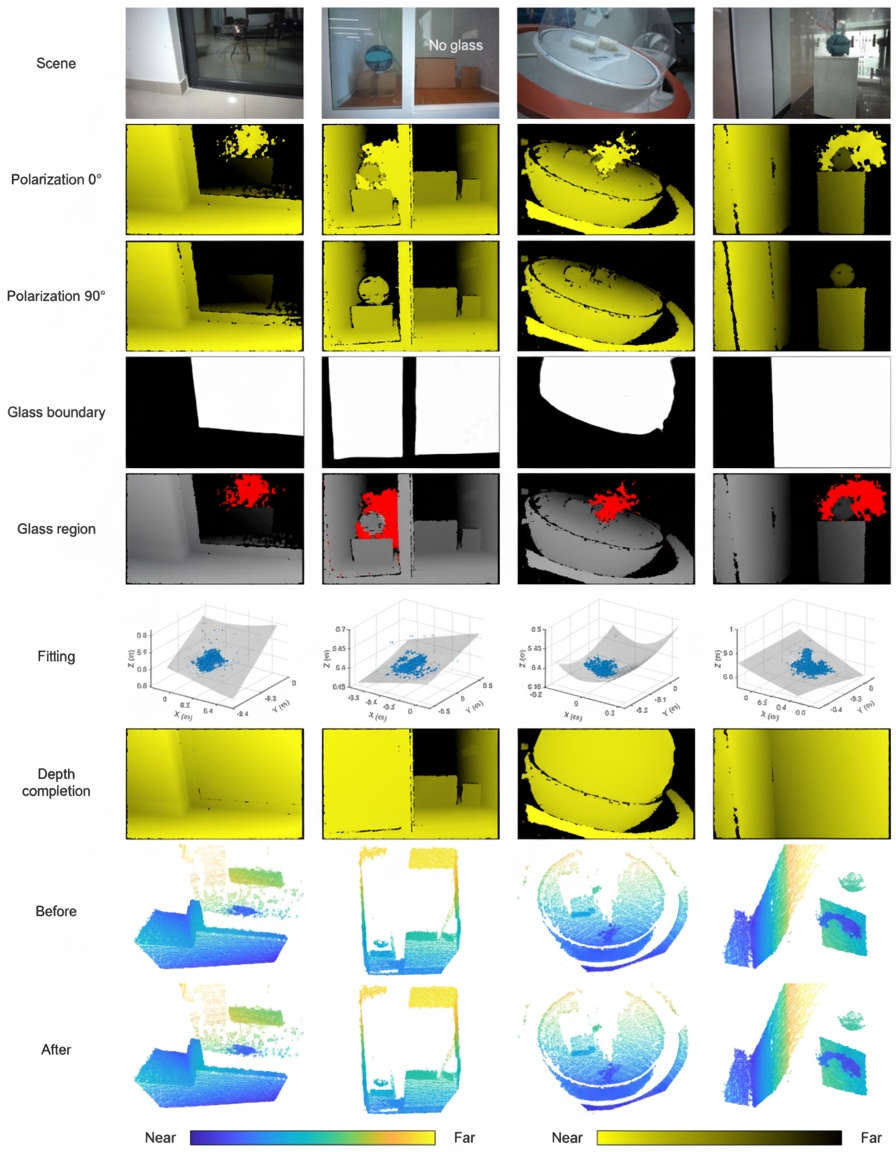

Beyond seeing through and suppressing reflection noise, the PSL 3D camera can also complete the geometry of reflective surfaces. The paper tested four common scenarios: balcony glass, acoustic-room glass, spherical glass, and office door glass (Figure 4). For each scene, two depth images were captured at RX polarizations of 0° and 90°. At 0°, both glass and diffuse regions are reconstructed; at 90°, the glass region is suppressed. This complementary change, which stereo cameras cannot produce for glass, provides a reliable cue for identifying reflective surfaces. By subtracting the two depth images and using predicted glass boundaries, the system extracts the depth belonging to the glass, shown in the fifth row of Figure 4. The extracted glass points are then used to fit and complete the reflective surface. The completed depth maps are displayed in the seventh row, with previously empty glass regions now filled. The final two rows compare the original and completed point clouds. The completed point clouds show correct 3D reconstruction of the reflective surfaces, validating the PSL 3D camera's approach.

Figure 3. Reflection completion experiment results

Conclusion

In summary, the Bosheng Optoelectronics team developed a polarization structured-light 3D camera based on HCG-VCSELs and presented associated imaging methods for 3D reconstruction across reflective-surface scenarios. As a visual sensor for robots, the PSL 3D camera addresses common reflective-surface challenges encountered by service and logistics robots, such as glass doors and tiled corner reflections demonstrated in the experiments. The camera enables correct handling of these situations and can benefit reflective-object or scene reconstruction in environments like offices and exhibition halls. With its polarization capabilities, the PSL 3D camera can be applied across a wide range of indoor and outdoor 3D applications.