Overview

Terahertz (THz) waves can penetrate most optically opaque materials, making them well suited for nondestructive detection of hidden objects and defects. Existing THz detection systems, however, are constrained by imaging speed and resolution, which limits throughput and accuracy. Machine vision systems that rely on large pixel arrays also face bottlenecks from data storage, transmission, and processing demands.

Published Work

Researchers at the University of California, Los Angeles (UCLA) recently published a paper in Nature Communications titled "Rapid sensing of hidden objects and defects using a single-pixel diffractive terahertz sensor." The paper lists Jingxi Li as first author and Aydogan Ozcan as corresponding author.

Concept and Approach

The study proposes a diffractive sensor that uses a single-pixel THz detector to rapidly detect hidden objects and defects inside 3D samples, avoiding sample scanning and image-formation or image-processing steps. With diffractive layers optimized by deep learning, the sensor encodes the sample's 3D structural information into the output spectrum and directly indicates whether hidden structures or defects are present. The authors experimentally validated the architecture using a single-pixel THz time-domain spectroscopy (THz-TDS) system and 3D-printed diffractive layers, successfully detecting previously unknown hidden defects in silicon samples. Potential applications include security screening, biomedical sensing, and industrial quality control.

Principle of Operation

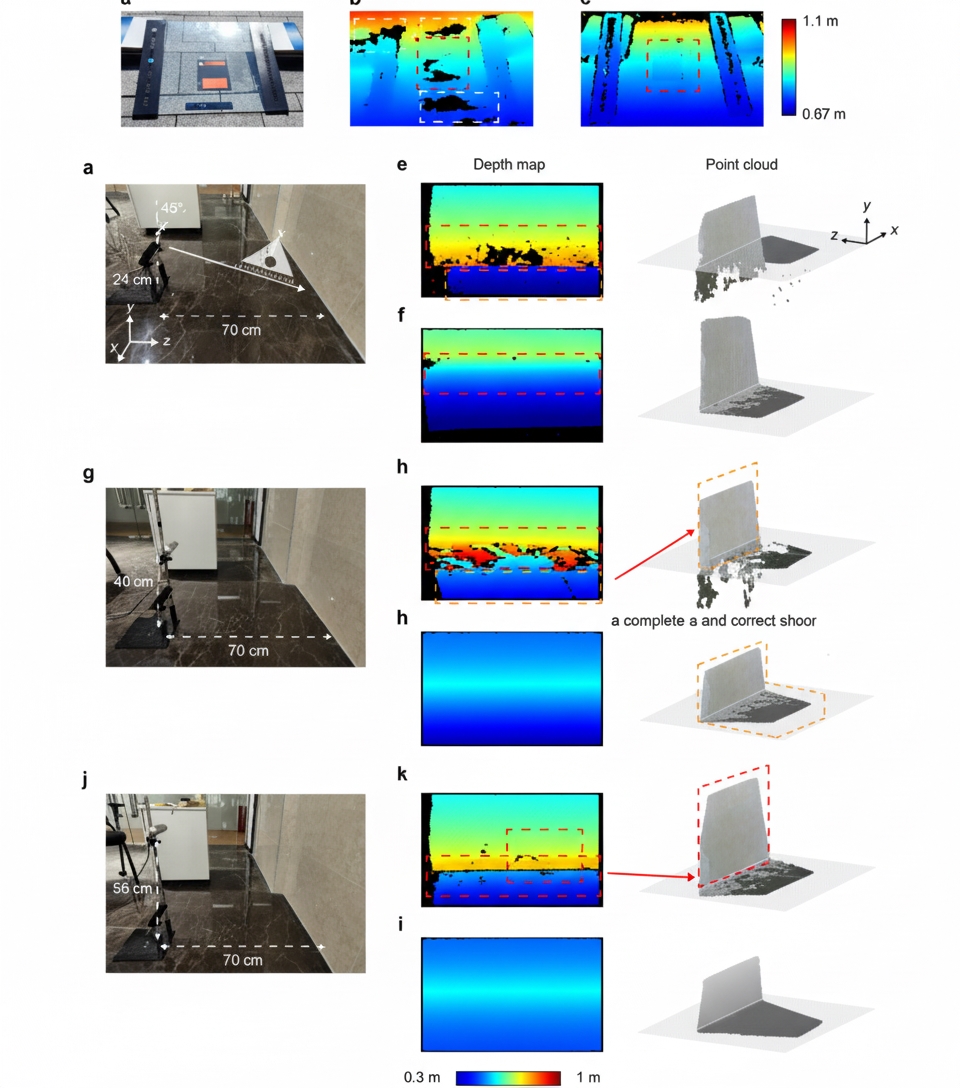

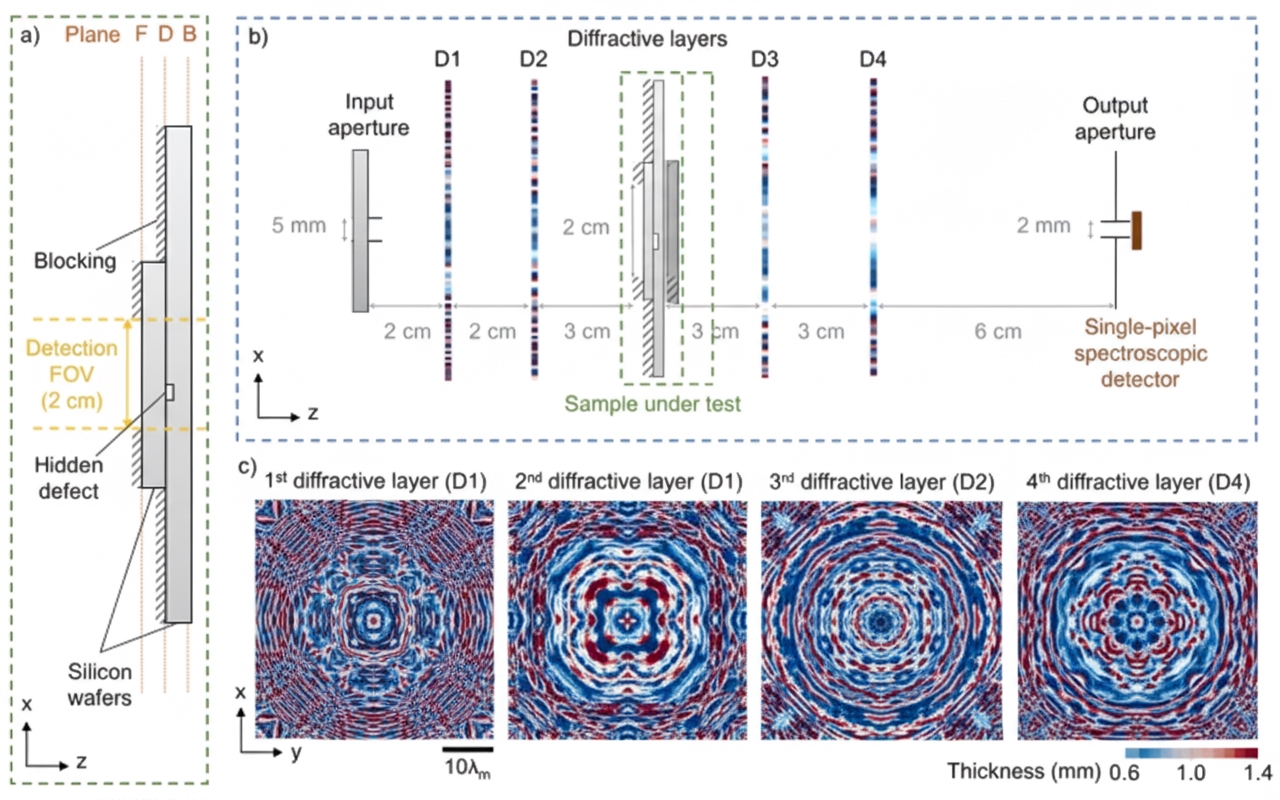

Figure 1 illustrates the basic principle of the proof-of-concept single-pixel diffractive THz sensor design. Its forward model can be viewed as a coherent optical system that processes spatially coherent THz waves at two preset wavelengths (λ1 and λ2), with diffraction and interference used for the defect-detection task.

Figure 1 Schematic of the diffractive THz sensor that uses a single-pixel spectroscopic detector to rapidly detect hidden objects and defects.

Proof-of-Concept Design for Silicon

To validate the nondestructive diffractive defect-detection architecture, the team designed a proof-of-concept single-pixel diffractive THz sensor (Figure 2) capable of detecting pore-like hidden defects in silicon that are invisible at the surface. This capability is widely valued in industrial contexts for assessing the quality, reliability, and performance of manufactured parts and products.

Figure 2 Single-pixel diffractive THz sensor design for detecting hidden defects in silicon wafers.

Performance Analysis

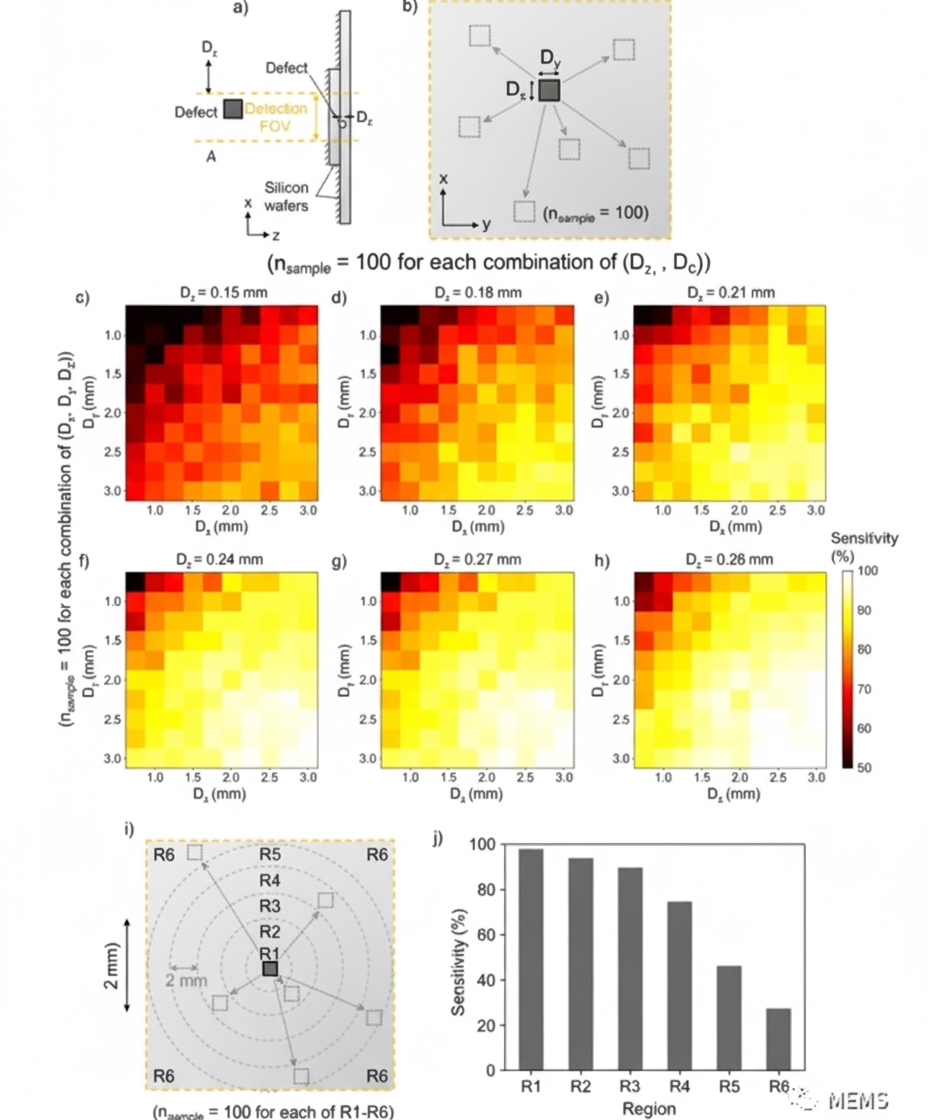

The researchers performed a comprehensive evaluation of the architecture's effectiveness using a decision threshold of 0.5, analyzing performance metrics such as detection sensitivity and defect-detection accuracy. The results are shown in Figure 3.

Figure 3 Performance analysis of the single-pixel diffractive THz sensor for detecting defects hidden in silicon test samples.

Experimental Validation

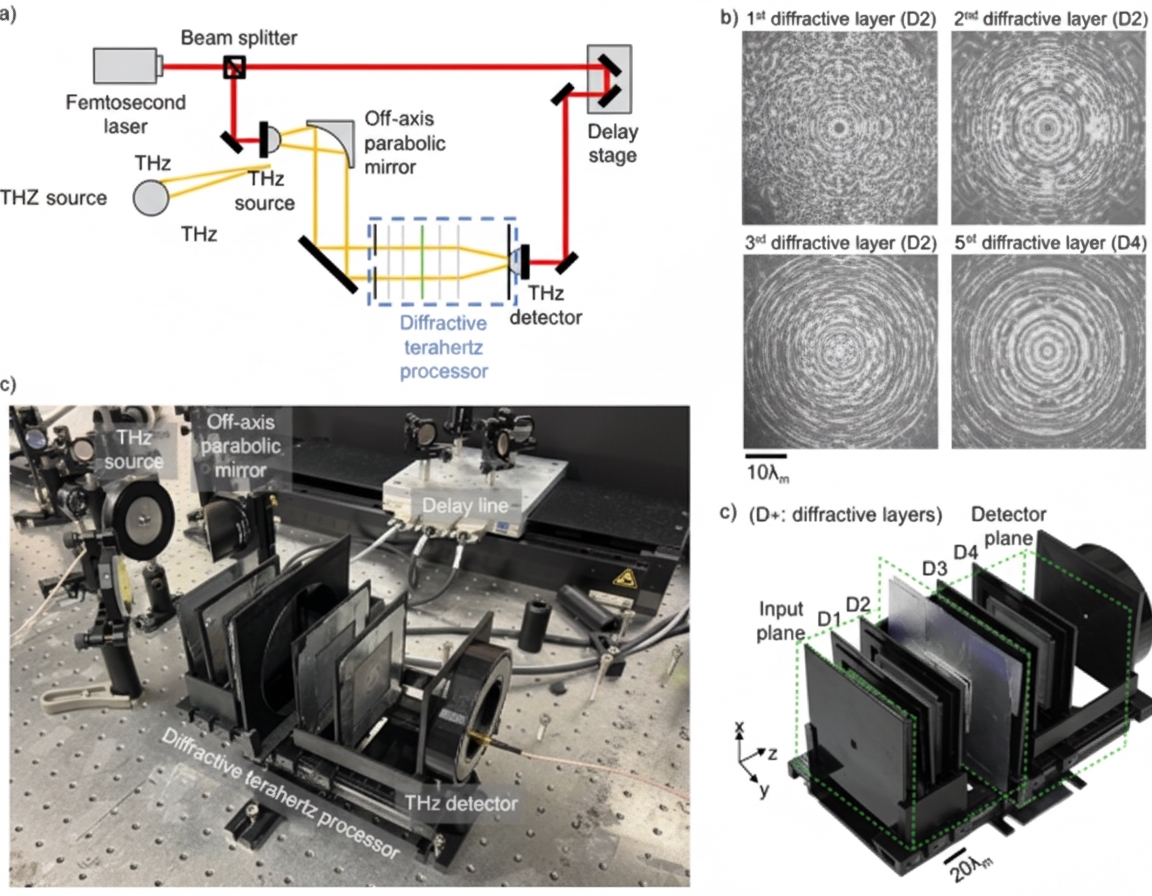

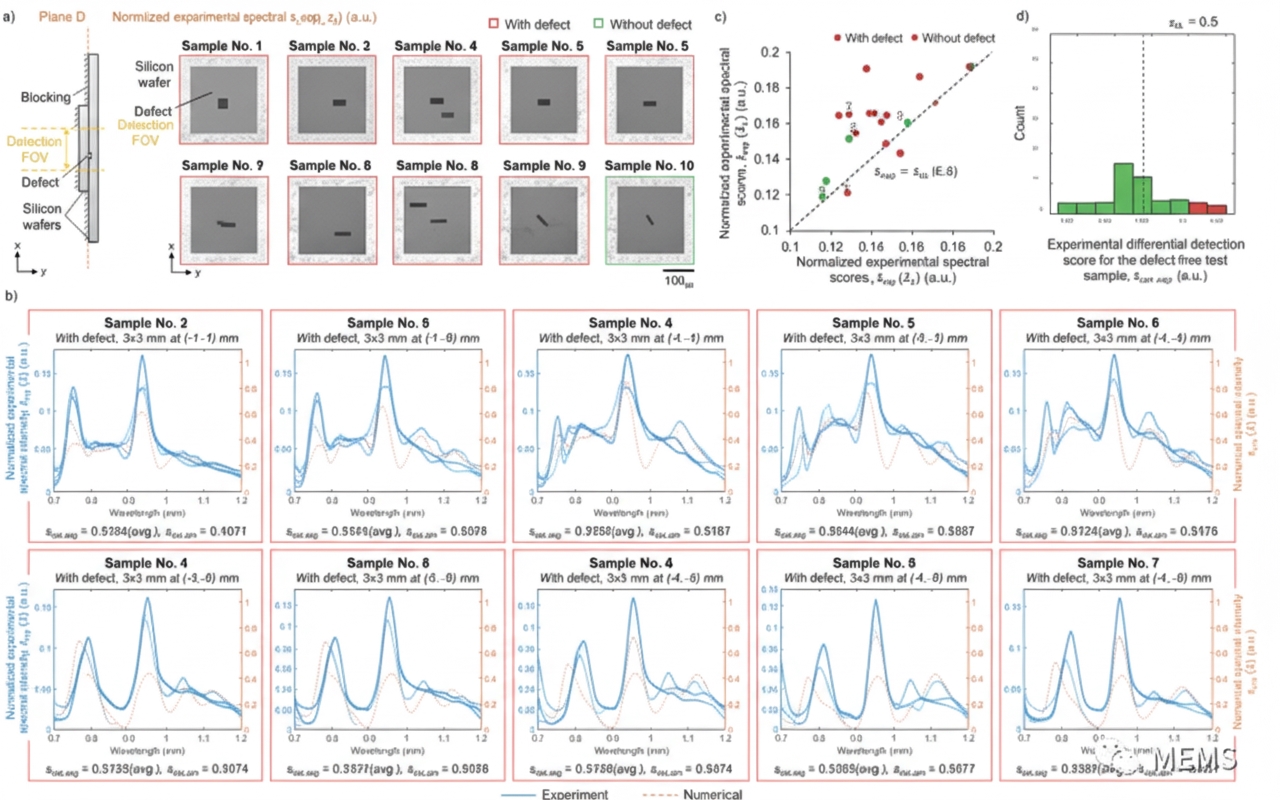

The diffractive design was experimentally validated using a THz-TDS setup with a plasmonic photoconductive source and a single-pixel detector (Figure 4a). Experimental results are presented in Figure 5.

Figure 4 Experimental setup for the single-pixel diffractive THz sensor.

Figure 5 Experimental results showing detection of defects hidden inside samples using the single-pixel diffractive THz sensor.

Conclusion

The study presents an all-optical, end-to-end diffractive sensor for rapid detection of hidden structures. The sensor uses a diffractive network composed of paired encoder and decoder layers, with each network performing structured illumination and spatial-spectral encoding. The proof-of-concept demonstrates that a single-pixel diffractive THz sensor, driven by pulsed illumination, can identify hidden defects of unknown shape and position within test samples with very low false alarm rates and without requiring image formation, acquisition, or digital processing steps.