Introduction

Through-hole soldering, often abbreviated as THT soldering, is a fundamental skill for electronic hobbyists venturing into circuit board assembly. This technique involves mounting components with leads that pass through holes in a printed circuit board (PCB) and securing them with solder on the opposite side. For beginners, mastering THT soldering opens the door to building and repairing a wide range of electronic projects, from simple LED circuits to complex audio amplifiers. This guide aims to provide a clear, step-by-step THT soldering tutorial, covering essential tools, techniques, and best practices. Whether you are choosing the best soldering iron for THT or learning proper joint formation, this article will equip you with the knowledge to achieve reliable and durable connections. Let’s explore the world of through-hole soldering and build a strong foundation for your electronics journey.

What Is Through-Hole Soldering and Why It Matters

Through-hole soldering is a method of assembling electronic components where leads are inserted into pre-drilled holes on a PCB and soldered to pads on the opposite side. This technique, also known as plated through-hole (PTH) soldering, has been a staple in electronics since the early days of circuit design. Unlike surface-mount technology (SMT), which places components directly on the board’s surface, THT provides stronger mechanical bonds, making it ideal for components subject to physical stress, such as connectors and switches.

For electronic hobbyists, THT soldering is often the starting point due to its simplicity and forgiving nature. The larger component sizes and visible leads make it easier to handle and inspect compared to tiny SMT parts. Additionally, many beginner kits and educational projects rely on through-hole components, emphasizing the importance of learning THT soldering techniques. A solid grasp of this skill ensures hobbyists can prototype ideas, repair devices, and understand foundational electronics assembly principles.

Related Reading: Essential Techniques for Soldering Through-Hole Components on Double-Sided PCBs

Technical Principles of Through-Hole Soldering

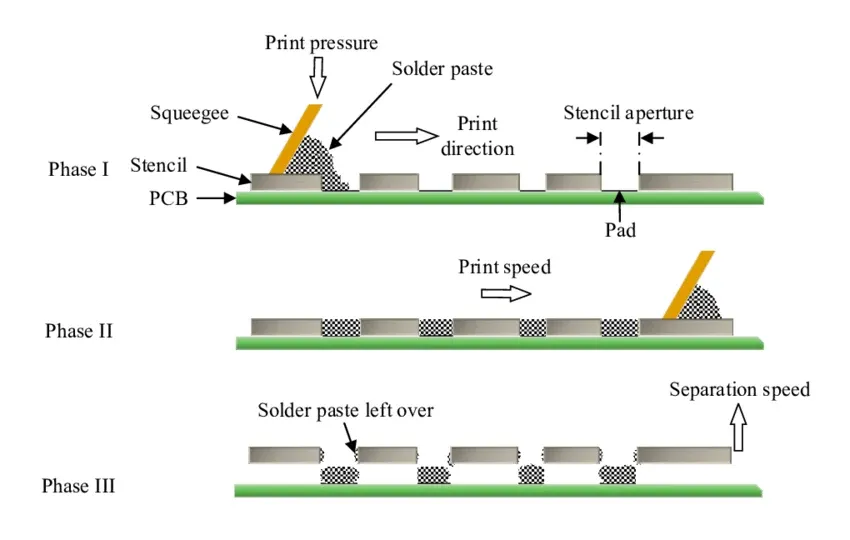

At its core, THT soldering relies on creating a reliable electrical and mechanical connection between a component lead and a PCB pad. The process involves heating the lead and pad with a soldering iron, then applying solder to form a joint as the materials cool. The solder, typically a tin-lead or lead-free alloy, must flow evenly into the hole and around the lead to ensure conductivity and strength.

A key principle is thermal management. The soldering iron must maintain a temperature sufficient to melt the solder without damaging the component or PCB. Most through-hole components and boards can handle temperatures between 260 to 315 degrees Celsius for a few seconds, as outlined in industry standards like IPC J-STD-001H for soldered electrical and electronic assemblies. Proper heat transfer ensures the solder wets both the lead and pad, forming a shiny, conical joint without cold or dry connections.

Another critical aspect is flux, a chemical agent that cleans surfaces by removing oxidation during soldering. Flux is often integrated into solder wire but can also be applied separately. It facilitates smooth solder flow and prevents defects like bridging, where solder connects unintended areas. Understanding these principles is essential for executing effective THT soldering techniques and avoiding common pitfalls.

Essential Tools for Through-Hole Soldering

Having the right tools is crucial for successful THT soldering. Below is a list of essential equipment for hobbyists starting with a THT soldering tutorial, along with guidance on selecting the best soldering iron for THT applications.

- Soldering Iron: The primary tool for heating and melting solder. For through-hole work, a 25 to 40-watt iron with a fine chisel or conical tip is ideal. Adjustable temperature models allow better control, especially for varying component sensitivities.

- Solder Wire: A tin-lead (60/40) or lead-free alloy with a rosin core flux is standard. Wire diameter between 0.5 to 1.0 mm works well for most THT tasks.

- Solder Wick or Desoldering Pump: Used to remove excess or incorrect solder. A desoldering pump is often easier for beginners to handle.

- Wire Cutters: For trimming component leads after soldering. Flush cutters provide clean cuts close to the board.

- Helping Hands or PCB Holder: These tools stabilize the board and components, freeing your hands for soldering.

- Safety Gear: Safety glasses protect eyes from solder splashes, and a well-ventilated workspace or fume extractor mitigates flux smoke exposure.

When choosing the best soldering iron for THT, prioritize models with quick heat recovery and replaceable tips. This ensures consistent performance across multiple joints without long wait times. Beginners should avoid overly powerful irons, as excessive heat can lift pads or damage components.

Related Reading: DIY SMD Soldering: Essential Tools and Techniques for Hobbyists

Best Practices for THT Soldering Techniques

Mastering THT soldering techniques requires attention to detail and consistent practice. Follow these steps to achieve clean, reliable joints while adhering to guidelines similar to those in IPC J-STD-001H for soldered assemblies.

- Prepare the Workspace: Ensure a clean, well-lit area with proper ventilation. Organize tools within reach to maintain focus during soldering.

- Inspect Components and Board: Check for bent leads or damaged pads. Straighten leads with pliers if needed, and clean the fast turn PCB with isopropyl alcohol to remove contaminants.

- Insert Components: Place leads through the designated holes, ensuring correct orientation for polarized components like diodes. Bend leads slightly on the underside to hold parts in place.

- Heat the Joint: Position the soldering iron tip to contact both the lead and pad simultaneously. Apply heat for 1 to 2 seconds before introducing solder.

- Apply Solder: Feed solder wire to the joint where the iron meets the lead and pad. Use just enough to form a small, shiny cone around the lead. Avoid excess solder that could cause shorts.

- Cool and Inspect: Remove the iron and let the joint cool naturally. A good joint appears smooth and concave. Dull or cracked joints indicate poor wetting and may need rework.

- Trim Leads: Use wire cutters to trim excess leads close to the solder joint, taking care not to damage the connection.

Consistency in heat application and solder amount is vital. Practice on scrap boards to refine your THT soldering techniques before working on actual projects. Always prioritize safety by avoiding contact with the hot iron tip and handling components with care.

Common Mistakes and Troubleshooting Tips

Even with careful preparation, beginners often encounter issues during THT soldering. Identifying and addressing these problems early prevents long-term damage to projects. Below are common pitfalls and solutions based on practical experience.

- Cold Joints: These occur when insufficient heat is applied, resulting in a dull, grainy joint. Reheat the joint with the iron and add a small amount of fresh solder to improve wetting.

- Solder Bridges: Excess solder can connect adjacent pads, causing shorts. Use a solder wick or desoldering pump to remove the bridge, then clean the area.

- Lifted Pads: Overheating or excessive force can separate pads from the board. Minimize iron contact time and avoid pulling on leads during desoldering.

- Component Damage: Prolonged heat exposure can harm sensitive parts. Use a heat sink, like a small alligator clip on the lead, to dissipate heat during soldering.

Regularly inspect joints visually after soldering. A magnifying glass can help spot subtle defects. Following standards like IPC-A-600K for PCB acceptability ensures hobbyists develop habits aligned with industry expectations, even at a beginner level.

Suggested Reading: THT Assembly Troubleshooting: Fixing Common Circuit Issues

Building Confidence Through Practice

For electronic hobbyists, confidence in THT soldering comes from hands-on experience. Start with simple kits, such as LED blinker circuits or resistor arrays, to practice basic joint formation. These projects often include detailed instructions and forgiving designs, allowing room for error as you learn. Gradually progress to more complex assemblies involving multiple component types to refine your skills.

Another effective approach is repairing old or broken electronics. Disassembling and resoldering joints on discarded devices provides real-world troubleshooting practice. Focus on maintaining clean workspaces and consistent techniques to build muscle memory. Over time, these efforts will transform THT soldering from a daunting task into a rewarding part of your hobby.

Conclusion

Through-hole soldering remains an essential skill for electronic hobbyists eager to explore the world of circuit assembly. This THT soldering tutorial has covered the fundamental principles, necessary tools, and best practices to help beginners create reliable connections. From selecting the best soldering iron for THT to mastering key techniques, each step builds toward proficiency in handling through-hole components. By understanding common mistakes and dedicating time to practice, hobbyists can achieve consistent, high-quality results. Embrace the learning process, adhere to established guidelines, and watch as your ability to build and repair electronics grows with every soldered joint.

FAQs

Q1: What is the best soldering iron for THT soldering as a beginner?

A1: For THT soldering, beginners should choose a 25 to 40-watt soldering iron with adjustable temperature control. A fine chisel or conical tip works well for through-hole components. This range provides enough heat for most joints without risking damage to the PCB or parts. Ensure the iron has quick heat recovery for consistent performance across multiple connections.

Q2: How can I improve my THT soldering techniques for cleaner joints?

A2: To enhance your THT soldering techniques, practice on scrap boards to perfect heat application and solder flow. Always clean the PCB and components before starting. Apply heat to both the lead and pad for 1 to 2 seconds before adding solder. Inspect joints for a shiny, conical shape, and rework any dull or uneven connections promptly.

Q3: What should I avoid during a THT soldering tutorial to prevent damage?

A3: During a THT soldering tutorial, avoid overheating by limiting iron contact to a few seconds per joint. Do not use excessive solder, as it can cause bridges between pads. Protect sensitive components with a heat sink if needed. Finally, ensure proper ventilation to avoid inhaling flux fumes, and never touch the hot iron tip.

Q4: Why are my through-hole solder joints not sticking properly?

A4: Poorly sticking joints often result from insufficient heat or dirty surfaces. Ensure your soldering iron reaches the correct temperature and contacts both the lead and pad. Clean the PCB and leads with isopropyl alcohol before starting. Adding fresh solder with flux can also improve wetting for better adhesion in THT soldering techniques.

References

IPC J-STD-001H — Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2021.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.