Introduction

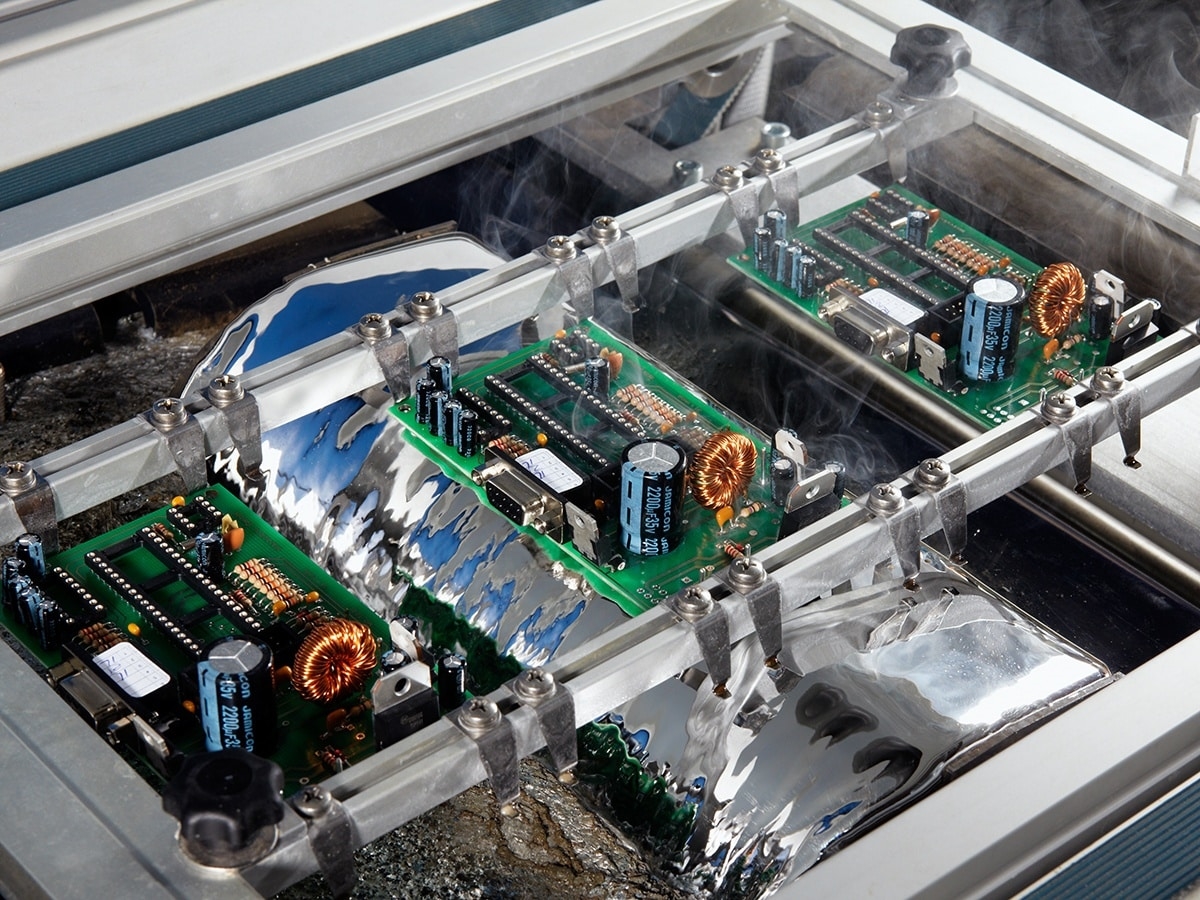

Wave soldering remains the most efficient method for soldering through-hole components and mixed-technology boards in medium-to-high volume production. A properly set-up wave solder machine can achieve defect rates below 100 ppm while processing hundreds of boards per hour. This beginner-friendly guide covers machine basics, process parameters, proven soldering techniques, common defects with solutions, and daily maintenance practices used on real production lines.

Wave Soldering Process Overview

- Flux application (spray or foam)

- Preheating (activates flux, reduces thermal shock)

- First wave (turbulent wave for wetting)

- Second wave (laminar wave for cosmetic fillet)

- Cooling (controlled or forced air)

Modern machines use inert nitrogen atmosphere to reduce dross and improve wetting on difficult finishes.

Essential Wave Solder Machine Components

- Spray fluxer with adjustable pressure and stroke

- Convection or IR preheat zones (top and bottom)

- Single or dual wave (chip wave + main wave)

- Titanium solder pot and pump system

- Conveyor with adjustable angle (4–7° typical)

Key Process Parameters and Beginner Settings

|

Parameter |

Recommended Starting Value |

Purpose |

|

Conveyor speed |

1.0–1.5 m/min |

Contact time control |

|

Preheat top/bottom |

90–110 °C board temperature |

Flux activation, thermal shock reduction |

|

Solder pot temperature |

255–265 °C (lead-free) |

Proper fluidity and wetting |

|

Wave height |

60–70 % of board thickness |

Full pin contact without bridging |

|

Conveyor angle |

6° |

Peel-off direction to reduce bridges |

|

Nitrogen flow |

800–1200 L/min |

Reduce dross and improve wetting |

Proven Soldering Techniques for Best Results

For fast turn PCB fabrication, wave solder reliability depends heavily on disciplined design and preparation.

- Pallet design: Use selective pallets for double-sided SMT boards

- Component orientation: Align long axes perpendicular to wave travel

- Pin protrusion: 1.0–2.0 mm above board bottom

- Thermal relief: Always use proper spoke patterns on planes

- Board cleanliness: Bake boards 4 h at 105 °C if stored > 3 months

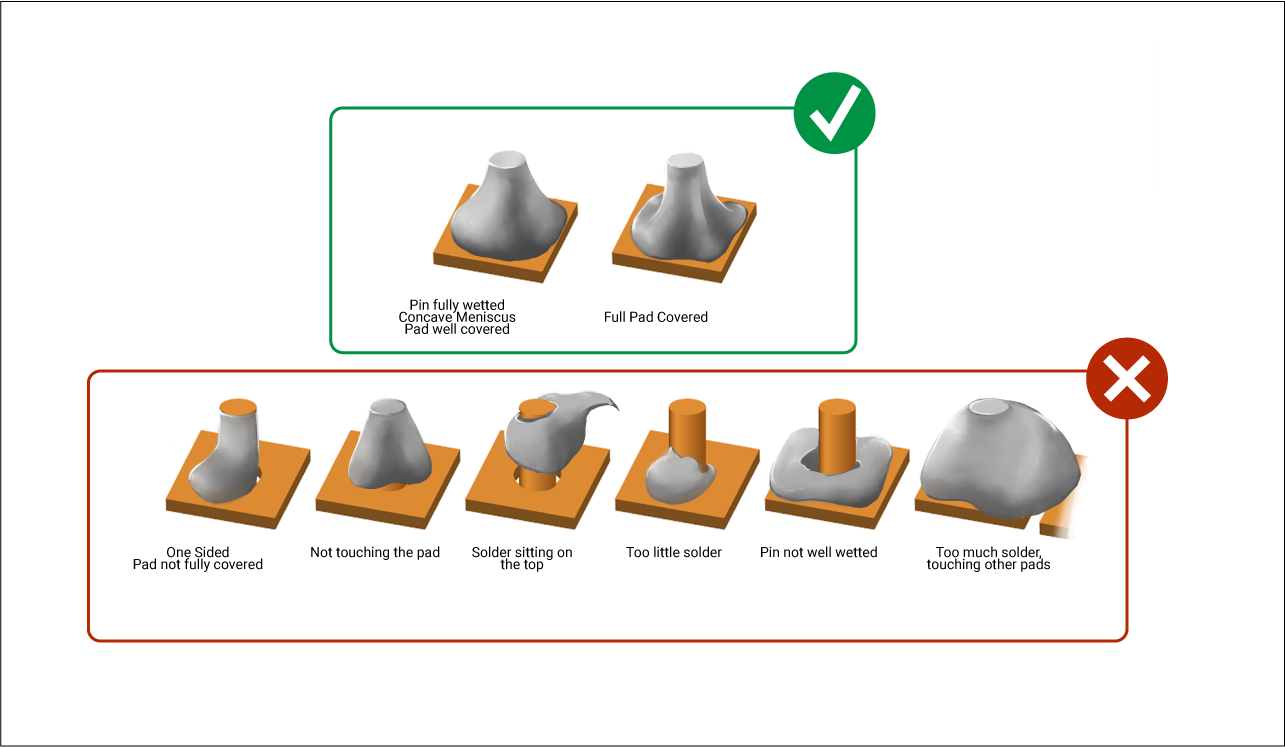

Common Soldering Defects and Fixes

|

Defect |

Typical Cause |

Solution |

|

Bridging |

Too slow speed, wrong peel-off, excess solder |

Increase conveyor speed, adjust angle to 6–7° |

|

Icicles/skewers |

Cold wave, poor flux activity |

Raise pot temperature 5–10 °C, check flux density |

|

Insufficient fill |

Short contact time, oxidized pins |

Lower wave height slightly, increase immersion |

|

Solder balls |

Excessive flux, moisture in board |

Reduce flux volume, pre-bake boards |

|

Dull/grainy joints |

Contaminated solder pot |

Regular dross removal, weekly pot cleaning |

Daily and Weekly Maintenance Tips

Daily

- Empty dross from wave nozzles

- Clean flux nozzles with IPA

- Check oil level in pump system

- Wipe titanium fingers and conveyor rails

Weekly

- Drain and filter solder pot (nitrogen machines)

- Calibrate temperature sensors

- Inspect pump impeller for wear

- Clean preheaters and exhaust filters

Lead-Free vs Leaded Wave Soldering

|

Parameter |

Sn63/Pb37 (Leaded) |

SAC305 (Lead-Free) |

|

Pot temperature |

245–255 °C |

260–270 °C |

|

Preheat target |

80–100 °C |

100–120 °C |

|

Typical defects |

Less bridging |

More icicles |

|

Dross formation |

Moderate |

High (nitrogen helps) |

Conclusion

Wave soldering delivers consistent, high-quality through-hole joints in PCBA assembly when process parameters stay within narrow windows. Start with the baseline settings above, adjust one parameter at a time while monitoring defect rates, and maintain rigorous daily cleaning. A well-maintained modern wave solder machine routinely achieves first-pass yields above 99.5 % on properly designed boards.

FAQs

Q1: Can I wave solder double-sided SMT boards?

A1: Yes, using selective pallets that cover top-side components while exposing only through-hole pins. Proper pallet design prevents component movement.

Q2: How often should I change the solder pot completely?

A2: Every 6–12 months for lead-free, longer for leaded. Copper accumulation above 1.0 % requires full replacement.

Q3: Why do I get bridges only on certain connectors?

A3: Pin spacing and orientation. Connectors with pins parallel to wave travel bridge easily. Rotate 90° or use selective pallet with dedicated channels.

Q4: Is nitrogen really necessary for wave soldering?

A4: Not mandatory for simple leaded boards, but essential for reliable lead-free results and OSP finish boards.

References

IPC J-STD-001H — Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2020.

IPC-7530A — Guidelines for Temperature Profiling for Mass Soldering Processes (Wave and Reflow). IPC, 2017.

IPC-A-610H — Acceptability of Electronic Assemblies. IPC, 2020.

IPC-HDBK-001H — Handbook and Guide to Supplement J-STD-001. IPC, 2020.