Introduction

In industries where electronics face extreme conditions, ensuring their reliability is paramount. Harsh environments, such as high temperatures, corrosive atmospheres, and mechanical stress, can degrade printed circuit boards (PCBs) and lead to failures. Conformal coating machines play a critical role in applying protective layers to safeguard electronics in such settings. This article explores the importance of conformal coating for high temperature applications, corrosive environments, and specialized uses in military, aerospace, and marine sectors. By understanding the technology and standards behind these solutions, engineers can select the right processes to enhance durability and performance in challenging conditions.

What Is Conformal Coating and Why It Matters

Conformal coating is a thin polymeric layer applied to PCBs to shield them from environmental hazards. This protective film conforms to the board's surface, covering components and solder joints to prevent damage from moisture, dust, chemicals, and thermal stress. In harsh environments, where electronics are exposed to extreme conditions, conformal coating becomes essential for maintaining operational integrity.

The relevance of conformal coating spans multiple industries. For military PCB, it ensures mission-critical systems withstand rugged conditions. In aerospace, it protects avionics from temperature fluctuations and vibration. Marine environments demand resistance to saltwater corrosion. Without proper coating, electronics risk short circuits, corrosion, and mechanical failure, leading to costly downtime or safety hazards. Conformal coating for corrosive environments and high temperature applications directly addresses these challenges, extending the lifespan of electronic assemblies.

Technical Principles of Conformal Coating in Harsh Environments

Conformal coating works by creating a barrier between the PCB and its surroundings. The coating material, often made of acrylic, silicone, or urethane, is selected based on the specific environmental threats. Each type offers distinct properties, such as thermal resistance for high temperature applications or chemical resistance for corrosive environments.

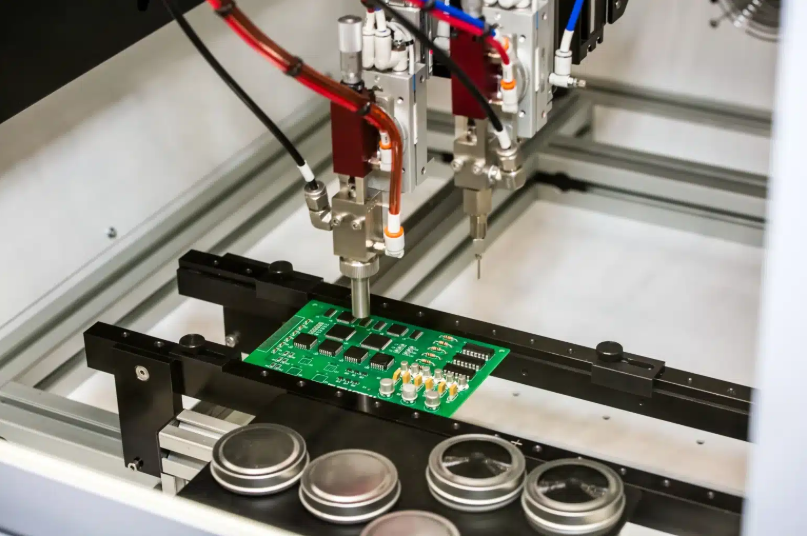

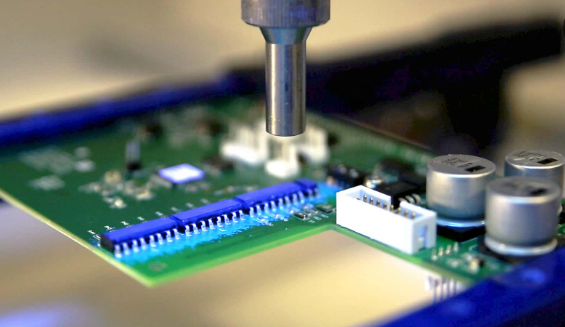

The application process, typically performed by conformal coating machines, ensures uniform coverage. These machines use methods like spraying, dipping, or brushing to apply the coating. Automated systems provide precision, especially for complex geometries, ensuring no area is left unprotected. The coating thickness, usually between 25 to 250 micrometers, must comply with industry standards to balance protection and functionality.

In extreme conditions, the coating must endure specific stresses. For conformal coating for military applications, it needs to resist vibration and shock. Aerospace applications require stability across wide temperature ranges, often from below freezing to over 100 degrees Celsius. Marine environments challenge coatings with constant exposure to humidity and salt. The right material and application method are critical to meeting these demands.

Key Challenges in Harsh Environments

Electronics in extreme conditions face multiple threats that test the limits of conformal coating. High temperatures can cause thermal expansion, leading to cracks in the coating or substrate. Corrosive environments, such as those with acidic gases or saltwater, erode unprotected areas. Mechanical stress, common in military and aerospace applications, can compromise the coating's adhesion.

To address these challenges, coatings must be tailored to the environment. For conformal coating for high temperature applications, silicone-based materials are often chosen for their ability to withstand heat without degrading. In corrosive settings, urethane coatings provide superior chemical resistance. Understanding the specific stressors in military, aerospace, and marine applications guides the selection of both material and application technology.

Conformal Coating Machines: Technology and Capabilities

Conformal coating machines are designed to deliver consistent and reliable protection. Automated systems, such as selective coating robots, target specific areas of a PCB, avoiding connectors or sensitive components. This precision is vital for complex assemblies used in aerospace and military sectors. Spray systems, on the other hand, offer rapid coverage for large-scale production.

Advanced machines incorporate features like programmable controls to adjust coating thickness and curing time. Ultraviolet inspection capabilities help verify coverage under specific lighting, ensuring no gaps exist. For harsh environment applications, machines must support a range of coating materials to match the environmental demands. Compatibility with industry standards ensures the process meets quality and performance expectations.

Best Practices for Applying Conformal Coating in Extreme Conditions

Selecting the right conformal coating process starts with understanding the operational environment. Engineers must evaluate factors like temperature range, exposure to chemicals, and mechanical stress. For conformal coating for aerospace applications, lightweight materials with high thermal stability are prioritized. Marine environments require coatings with exceptional moisture and salt resistance.

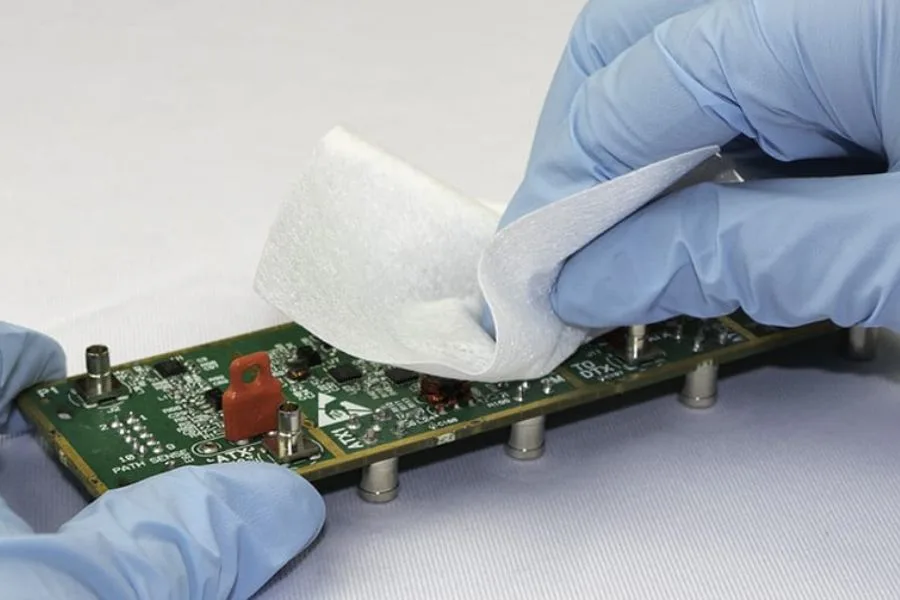

Surface preparation is a critical step. PCBs must be cleaned thoroughly to remove contaminants like flux residues or oils. Poor adhesion due to improper cleaning can lead to coating failure. Following cleaning, the application method should align with the board's design. Selective coating is ideal for intricate layouts, while dipping suits simpler assemblies.

Curing the coating properly is equally important. Whether using thermal, ultraviolet, or moisture curing, the process must adhere to specified conditions to achieve full protection. Regular inspection, guided by recognized standards, verifies the coating's integrity. These practices ensure reliability in high temperature and corrosive environments.

Industry Standards for Conformal Coating in Harsh Environments

Adhering to established standards is essential for ensuring the quality of conformal coating in extreme conditions. The IPC-CC-830C standard outlines the qualification and performance requirements for conformal coatings. It specifies testing methods for thermal shock, moisture resistance, and dielectric properties, directly applicable to military and aerospace needs.

Another key standard, MIL-I-46058C, focuses on insulating compounds for electronics, often referenced for military applications. It defines criteria for environmental resistance, ensuring coatings protect against harsh conditions. Compliance with these standards validates the coating's ability to perform in challenging settings, providing engineers with confidence in their selections.

Tailored Applications: Military, Aerospace, and Marine Sectors

Conformal coating for military applications often involves ruggedized electronics exposed to combat conditions. Coatings must resist abrasion, extreme temperatures, and chemical exposure. Automated conformal coating machines ensure consistent application for military PCB mass production.

In aerospace, conformal coating for aerospace applications protects avionics from altitude-related temperature swings and vibration. Lightweight coatings that do not add significant weight are preferred. Application precision is critical to avoid interference with sensitive components.

Marine environments present unique challenges due to constant humidity and saltwater exposure. Conformal coating for marine environments focuses on preventing corrosion and maintaining functionality in wet conditions. Selecting materials with hydrophobic properties enhances protection in these settings.

Conclusion

Conformal coating machines are indispensable for protecting electronics in harsh environments. From high temperature applications to corrosive settings, these systems ensure PCBs remain functional under extreme conditions. By adhering to industry standards and selecting appropriate materials, engineers can address the specific needs of military, aerospace, and marine applications. Understanding the technology and best practices behind conformal coating empowers professionals to enhance the reliability and longevity of electronic systems, no matter the environmental challenges they face.

FAQs

Q1: What are the best materials for conformal coating for high temperature applications?

A1: Silicone-based coatings are often preferred for high temperature applications due to their thermal stability. They can withstand wide temperature ranges without cracking or degrading. Engineers should select materials that meet standards like IPC-CC-830C to ensure performance. Testing under simulated conditions helps confirm the coating's suitability for specific temperature stresses.

Q2: How does conformal coating for corrosive environments protect electronics?

A2: Conformal coating for corrosive environments, such as urethane-based options, creates a chemical-resistant barrier. This shield prevents acids, salts, and other corrosive agents from reaching the PCB. Proper application and adherence to standards ensure long-term protection. Regular inspection identifies any degradation before failure occurs in harsh settings.

Q3: Why is conformal coating for military applications critical for reliability?

A3: Conformal coating for military applications ensures electronics survive rugged conditions like shock, vibration, and extreme weather. It prevents short circuits and corrosion in mission-critical systems. Compliance with standards like MIL-I-46058C validates performance. Precision application with automated machines guarantees consistent protection for military hardware.

Q4: What challenges arise with conformal coating for marine environments?

A4: Conformal coating for marine environments must resist constant humidity and saltwater exposure. Corrosion is a primary concern, requiring hydrophobic and chemically resistant materials. Poor adhesion or incomplete coverage can lead to failures. Following strict cleaning and application protocols ensures the coating maintains integrity in wet conditions.

References

IPC-CC-830C — Qualification and Performance Specification for Conformal Coatings. IPC, 2021.

MIL-I-46058C — Insulating Compound, Electrical (for Coating Printed Circuit Assemblies). U.S. Department of Defense, 1991.