Introduction

Conformal coating plays a vital role in protecting printed circuit boards (PCBs) from environmental hazards like moisture, dust, chemicals, and temperature extremes. For electrical engineers, choosing the right application method between dip and spray conformal coating machines is a critical decision that impacts reliability, production efficiency, and cost. This article explores the advantages of dip conformal coating machines and spray conformal coating machines, compares dip coating versus spray coating for PCBs, and outlines key conformal coating machine selection criteria. Additionally, it addresses conformal coating thickness control to ensure optimal performance. By understanding the technical nuances of each method, engineers can make informed decisions tailored to their specific application needs, ensuring long-term protection of electronic assemblies in demanding environments.

What Is Conformal Coating and Why It Matters

Conformal coating is a thin polymeric film applied to PCBs to shield electronic components from environmental stressors. It acts as a barrier against moisture, corrosion, and mechanical stress while maintaining electrical insulation. This protection is essential for industries such as aerospace, automotive, and medical, where reliability under harsh conditions is non-negotiable. Without proper coating, multilayer PCBs are vulnerable to failures caused by short circuits, corrosion, or thermal degradation.

The application method, whether dip or spray, directly influences the coating's uniformity, thickness, and adhesion. Selecting the appropriate conformal coating machine ensures consistent results, reduces material waste, and aligns with production volume requirements. For electrical engineers, understanding these methods is crucial to meeting industry standards like IPC-CC-830C, which governs conformal coating qualifications and performance. The choice between dip and spray can significantly affect both product quality and manufacturing efficiency.

Technical Principles of Dip and Spray Conformal Coating

Dip Conformal Coating Machines

Dip coating involves immersing a fast turn PCB into a tank of liquid conformal coating material. The board is submerged and then withdrawn at a controlled rate, allowing excess material to drain off. This method relies on surface tension and viscosity to achieve a uniform layer. The primary advantage lies in its simplicity and ability to coat complex geometries, including through-holes and under components, with minimal operator intervention.

The process is governed by factors such as immersion speed, withdrawal rate, and material viscosity. Slower withdrawal rates often result in thinner coatings, while faster rates increase thickness. Dip coating is ideal for high-volume production where consistent coverage is needed without intricate masking. However, it may lead to pooling in low areas or bubbles if not properly controlled, impacting conformal coating thickness control.

Spray Conformal Coating Machines

Spray coating applies conformal material as a fine mist using pneumatic or ultrasonic nozzles. The PCB is placed on a conveyor or held stationary while the spray head moves over it, depositing a controlled layer. This method offers precision, allowing operators to target specific areas and adjust thickness by varying spray patterns or passes.

Spray systems excel in flexibility, accommodating low to medium production volumes and complex board designs requiring selective coating. The process depends on parameters like nozzle distance, pressure, and material flow rate. While spray coating minimizes material waste compared to dipping, it often requires masking to protect connectors or sensitive components. Proper setup ensures uniform coverage, but operator skill and equipment calibration are critical for achieving desired results.

Advantages of Dip Conformal Coating Machines

Dip conformal coating machines offer several benefits for specific PCB applications. These advantages make them a preferred choice in certain manufacturing scenarios:

- Complete coverage: Immersion ensures all surfaces, including hard-to-reach areas under components, receive uniform coating. This is critical for boards with dense layouts.

- High throughput: Suitable for large-scale production, dip coating processes multiple boards simultaneously, reducing cycle time in high-volume environments.

- Minimal skill requirement: The automated nature of dip systems reduces reliance on operator expertise, ensuring consistent results with basic training.

- Cost effectiveness for volume: Lower equipment and operational costs compared to advanced spray systems make dip coating economical for bulk manufacturing.

These dip conformal coating machine advantages are particularly relevant for applications where speed and full coverage outweigh the need for selective application. However, challenges like material waste and difficulty in controlling thickness may limit its use in precision-focused projects.

Advantages of Spray Conformal Coating Machines

Spray conformal coating machines provide distinct benefits that cater to a variety of PCB protection needs. Their strengths include:

- Precision application: Spray systems allow targeted coating, ideal for boards with areas that must remain uncoated, such as connectors or test points.

- Material efficiency: By controlling spray volume and pattern, these machines minimize waste compared to dip methods, reducing material costs.

- Flexibility: Adjustable settings accommodate different board sizes and coating thicknesses, supporting low to medium production runs or prototypes.

- Adaptability to complex designs: Spray systems handle intricate PCB layouts with ease, applying coating only where needed through programmable paths or manual operation.

These spray conformal coating machine advantages make them suitable for applications requiring customization and precision. However, they may demand more setup time and skilled operation to achieve optimal results, especially for conformal coating thickness control.

Dip Coating vs Spray Coating for PCB Applications

When comparing dip coating versus spray coating for PCBs, several factors influence the choice of method. Both approaches have unique strengths and limitations, depending on the application requirements.

- Coverage: Dip = full immersion ensures complete coating; Spray = selective application with masking.

- Production volume: Dip = ideal for high-volume runs; Spray = best for low to medium volumes.

- Material usage: Dip = higher waste due to excess drainage; Spray = lower waste with controlled application.

- Thickness control: Dip = limited control with risk of pooling; Spray = better precision through adjustable settings.

- Setup complexity: Dip = simple setup with minimal masking; Spray = requires masking and calibration.

Dip coating excels in scenarios where uniform coverage and high throughput are priorities, such as in consumer electronics with standardized designs. Spray coating, however, is preferred for aerospace or medical devices where specific areas must remain uncoated, and precision is paramount. Engineers must weigh these aspects against project goals to determine the best fit.

Conformal Coating Machine Selection Criteria

Selecting the right conformal coating machine involves evaluating multiple parameters to align with production needs and quality standards. Below are key conformal coating machine selection criteria for electrical engineers to consider:

- Application requirements: Determine if full coverage or selective coating is needed. Dip systems suit uniform application, while spray systems offer precision for complex boards.

- Production volume: Assess batch sizes. Dip coating supports high-volume production, whereas spray systems are adaptable to smaller runs or prototyping.

- Material compatibility: Ensure the machine handles the chosen coating material, such as acrylic, silicone, or urethane, per specifications like IPC-CC-830C.

- Thickness control: Evaluate the ability to achieve consistent coating thickness. Spray systems often provide finer control compared to dip methods.

- Cost and maintenance: Consider initial investment, operational costs, and maintenance needs. Dip systems may have lower upfront costs, while spray systems could save on material over time.

By systematically analyzing these factors, engineers can select a machine that balances performance, efficiency, and budget constraints, ensuring reliable PCB protection.

Best Practices for Conformal Coating Thickness Control

Achieving consistent conformal coating thickness control is essential for meeting performance standards and avoiding issues like cracking or insufficient protection. Here are practical strategies for both dip and spray methods:

- Material viscosity monitoring: Regularly check and adjust the coating material's viscosity. For dip coating, consistent viscosity prevents uneven layers. For spray coating, it ensures proper atomization.

- Process parameter optimization: In dip coating, control immersion and withdrawal speeds to manage thickness. In spray coating, adjust nozzle distance and pressure for uniform application.

- Environmental conditions: Maintain stable temperature and humidity in the coating area. Fluctuations can affect material behavior and curing, impacting thickness.

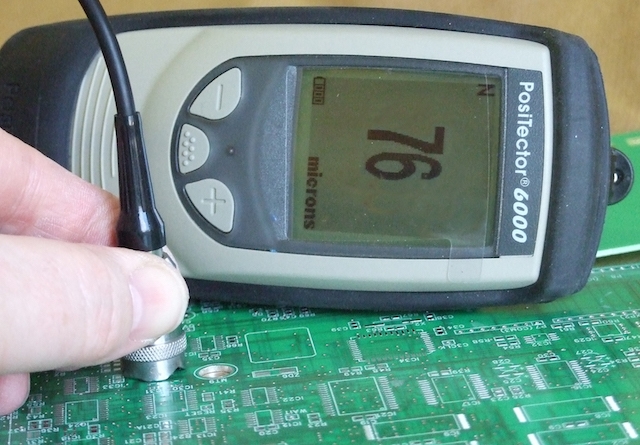

- Inspection and testing: Use non-destructive measurement tools to verify thickness post-application. Adhere to standards like IPC-A-600K for acceptability criteria during quality checks.

Implementing these practices minimizes variability and ensures the coating meets protective requirements without compromising electrical performance.

Troubleshooting Common Coating Challenges

Both dip and spray coating methods can encounter issues that affect PCB reliability. Addressing these challenges proactively is crucial for maintaining quality.

For dip coating, common problems include bubbles and pooling. Bubbles often result from air entrapment during immersion, which can be mitigated by degassing the coating material before use. Pooling occurs in low areas due to gravity; adjusting withdrawal speed and board orientation helps reduce this effect.

For spray coating, uneven application and overspray are frequent concerns. Uneven layers may stem from inconsistent nozzle movement or pressure, requiring calibration of the machine. Overspray can be minimized by using proper masking techniques and optimizing spray patterns to focus on target areas.

Regular equipment maintenance and operator training are essential to prevent these issues, ensuring consistent results across production batches.

Conclusion

Choosing between dip and spray conformal coating machines requires a thorough understanding of application needs, production goals, and quality requirements. Dip conformal coating machine advantages include full coverage and high throughput, making them ideal for large-scale, uniform applications. Spray conformal coating machine advantages lie in precision and material efficiency, suiting complex or selective coating tasks. By comparing dip coating versus spray coating for PCBs and applying conformal coating machine selection criteria, engineers can align their choice with project demands. Additionally, focusing on conformal coating thickness control ensures optimal protection and reliability. With the right approach, either method can deliver robust PCB protection tailored to specific environmental challenges.

FAQs

Q1: What are the main dip conformal coating machine advantages for high-volume PCB production?

A1: Dip coating offers complete coverage and high throughput, making it ideal for large-scale manufacturing. It coats all surfaces, including under components, with minimal operator intervention. This method reduces cycle times by processing multiple boards at once, ensuring efficiency while maintaining consistent results as per standards like IPC-CC-830C.

Q2: How do spray conformal coating machine advantages support complex PCB designs?

A2: Spray coating provides precision and flexibility, allowing selective application on specific areas. It minimizes material waste through controlled spraying and adapts to intricate layouts by avoiding sensitive components. This makes it suitable for low to medium volumes or prototypes where customization is key for reliable protection.

Q3: What factors should be considered in conformal coating machine selection criteria for PCB applications?

A3: Evaluate application needs, production volume, material compatibility, thickness control, and cost. Determine if full or selective coating is required, assess batch sizes, and ensure alignment with standards like IPC-A-600K. Balancing performance with budget and maintenance needs ensures the machine meets project specifications effectively.

Q4: How can engineers ensure conformal coating thickness control during application?

A4: Monitor material viscosity, optimize process parameters like speed or pressure, and maintain stable environmental conditions. Use inspection tools to verify thickness post-application, adhering to acceptability criteria in standards like IPC-A-600K. Consistent control prevents issues like cracking or inadequate protection on PCBs.

References

IPC-CC-830C — Qualification and Performance Specification for Conformal Coatings. IPC, 2018.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.