Why is Component Lead Forming Critical in Electronics Manufacturing?

Component lead forming is the precise shaping of an electronic component's wires, or "leads," to ensure they fit correctly onto a printed circuit board (PCB). This process is vital for through-hole technology, where components like resistors, capacitors, and diodes are inserted into pre-drilled holes and then soldered. Proper lead formation guarantees secure physical mounting, safeguards components from damage, and maintains the electrical integrity of the circuit.

Failing to form leads accurately can lead to numerous problems, including intermittent connections, excessive mechanical stress on components, or even undesirable short circuits. For instance, leads that are too long might inadvertently contact neighboring traces or components, creating an electrical fault. Conversely, overly short leads might not extend sufficiently through the fast turn PCB for a strong solder joint. Therefore, mastering lead forming is indispensable for both manual and automated assembly workflows, enhancing the longevity and efficiency of the final electronic product.

Understanding Different Component Lead Types: Axial vs. Radial

Axial Component Lead Characteristics

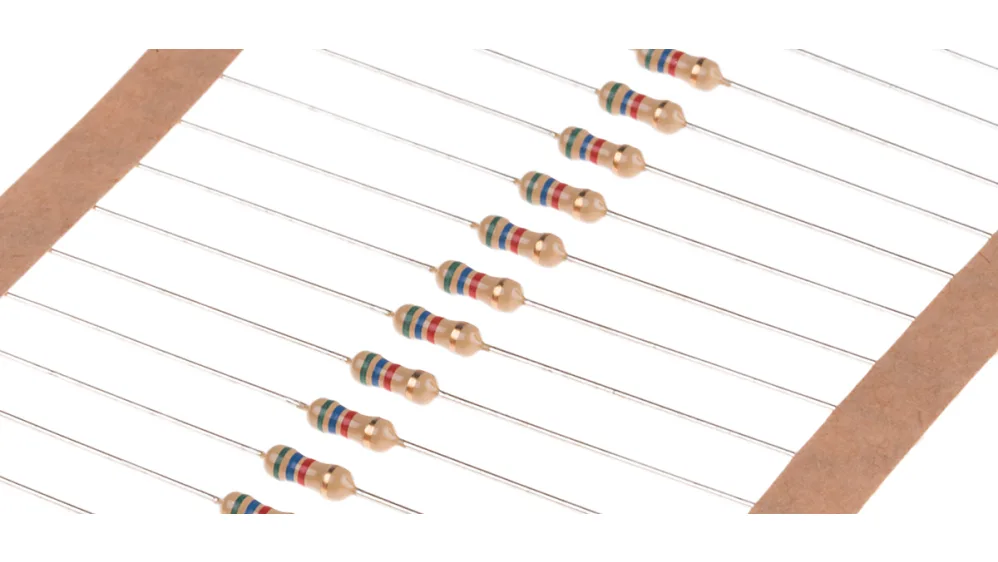

Axial components are designed with leads extending from opposing ends of their cylindrical or bar-shaped body. Common examples include various resistors and certain types of diodes. Their leads are collinear with the component's main axis, necessitating specific bends to span the distance between widely spaced holes on a PCB.

Radial Component Lead Characteristics

In contrast, radial components feature leads that originate from a single side of the component body, running parallel to each other. Electrolytic capacitors frequently employ this configuration. These leads typically require minimal bending but demand precise alignment to ensure the component sits correctly and its leads slot into the designated PCB holes without strain.

Best Practices for Axial Lead Forming

Step-by-Step Axial Lead Preparation

1. Measure Hole Pitch: Begin by accurately measuring the spacing between the mounting holes on your PCB. Standard through-hole designs typically have pitches ranging from 2.54 mm (0.1 inches) to 12.7 mm (0.5 inches).

2. Employ Proper Tooling: Always use specialized lead bending pliers with rounded jaws or dedicated forming jigs. Bending leads by hand can result in inconsistent shapes and potential damage to the component or lead.

3. Ensure Safe Bend Distance: Position the bend at least 1-2 mm away from the component body. This clearance prevents internal damage or cracking, especially for sensitive components. A typical quarter-watt resistor, for example, can safely accommodate a bend radius of approximately 0.8 mm.

4. Achieve 90-Degree Angles: For most axial components, bend the leads to a precise 90-degree angle. Symmetrical bends on both leads are crucial for a stable and aesthetically pleasing fit.

5. Trim Excess Length: Once the component is inserted, trim the leads to extend about 1-2 mm beyond the PCB’s surface. This length is ideal for robust soldering without creating excess material that could lead to shorts.

Key Considerations for Axial Lead Forming

● For consistent results, especially in mass production, always use a forming tool or specialized jig.

● Avoid creating sharp creases in the leads, as these can weaken the metal; instead, aim for smooth, gentle radii.

● Handle components delicately to prevent mechanical stress, as components with ceramic or glass bodies are particularly susceptible to cracking from excessive force.

Achieving Precision with Radial Lead Forming

Radial Lead Adjustment Techniques

1. Verify Lead-to-Hole Alignment: Compare the component's lead spacing (pitch), often a standard like 5 mm or 10 mm, with the corresponding hole spacing on the PCB.

2. Gentle Lead Adjustment: If a slight adjustment is needed, use small pliers or a specialized tool to gently widen or narrow the lead spacing. Avoid applying excessive force to prevent stressing the component.

3. Ensure Flush Seating: Radial components should sit flat against the PCB surface. If the leads are too long, a small trim before insertion can help achieve the correct mounted height, typically 2-3 mm above the board after soldering.

4. Careful Insertion: Guide the leads through the PCB holes, ensuring the component is stable before soldering. Avoid forceful insertion, which can bend or break leads.

Best Practices for Radial Lead Handling

● Minimize lead bending for radial components to reduce stress on both the leads and the component body.

● For high volume PCB assembly, utilize a lead forming jig to maintain consistent lead uniformity.

● Always confirm the correct polarity for components such as electrolytic capacitors, as incorrect orientation can result in circuit malfunction.

Essential Tools for Accurate Lead Bending

Selecting the appropriate lead bending tools is paramount for enhancing both the quality and efficiency of the lead forming process.

● Needle-Nose Pliers: These are versatile for manual bending of both axial and radial leads. Opt for pliers with smooth, rounded tips to prevent nicking or scoring the leads.

● Lead Forming Jigs: These fixtures provide templates for creating uniform bends at precise angles and distances. They are particularly valuable for axial components in batch manufacturing.

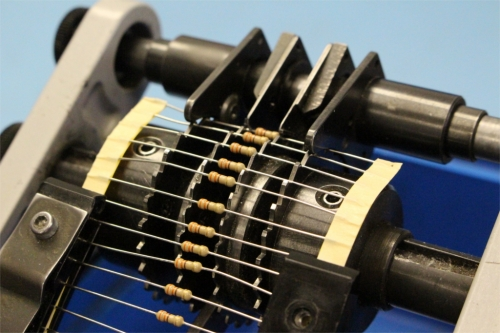

● Automated Lead Formers: For high-volume production, automated machines can form and trim leads with exceptional precision, processing thousands of components hourly. These systems typically offer customizable settings for various component sizes and lead pitches.

● Precision Cutters: After forming and insertion, use flush cutters to trim any excess lead length. Tools with fine tips are best for navigating densely populated PCBs.

Investing in high-quality tools not only saves time but also significantly reduces the potential for component damage during lead formation. For example, a well-engineered lead former can achieve bend accuracy within 0.1 mm, ensuring perfect alignment every time.

Related Reading: Beyond Pick and Place: Advanced Robotics in Automated PCB Assembly

Optimal Lead Cutting Techniques for a Professional Finish

After leads are properly formed and components are inserted, trimming excess lead length is the final critical step. Adhering to lead cutting best practices ensures a clean, professional appearance and prevents issues during subsequent soldering or product operation.

Effective Lead Trimming Strategy

● Cut Post-Insertion: Always trim leads after the component is securely seated in the PCB to prevent any misalignment.

● Maintain Adequate Length: Trim leads to a length of 1-2 mm extending beyond the PCB surface. This provides sufficient material for a strong solder joint without creating excess that could cause shorts or interfere with adjacent components.

● Utilize Sharp Cutters: Dull cutting tools can crush or deform leads, which negatively impacts solder joint quality. Employ sharp, precision flush cutters for consistently clean cuts.

● Angle the Cut: Trimming leads at a slight angle (around 45 degrees) can create a pointed tip, which often aids in optimal solder flow during the assembly process.

● Manage Debris: Perform lead cutting over a containment tray or use a tool equipped with a debris catcher. This prevents small metal clippings from scattering across the workspace or PCB, where they could potentially cause short circuits.

Proper lead cutting not only improves the visual appeal of the circuit board but also significantly contributes to its overall reliability. Industry studies on assembly defects indicate that leaving leads excessively long on densely packed boards can elevate the risk of short circuits by as much as 15%.

Addressing Common Challenges in Leaded Assembly

Even with meticulous techniques, leaded assembly can present its own set of challenges. Here are frequent issues and their respective solutions for a smoother process:

● Component Damage: Excessive force during bending is a primary cause of component cracking or breakage. Always use tools specifically designed for lead forming and handle components with care.

● Inconsistent Bends: Manual bending frequently results in uneven lead forms. For uniformity, especially in larger production volumes, rely on jigs or automated forming equipment.

● Lead Stress: Bending leads too close to the component body can weaken the lead or internal connections. Maintain a safe distance (1-2 mm) from the body during the forming process.

● Short Circuits from Debris: Tiny metal clippings from lead trimming can cause short circuits if not properly contained. Use a debris catch or industrial vacuum to maintain a clean workspace.

Manual vs. Automated Lead Forming: Which Method Suits Your Needs?

The choice between manual and automated component lead forming largely depends on your production volume and available budget.

Comparison of Lead Forming Methods

● Cost: Manual lead forming is low-cost (basic tools typically range from (10-50). Automated systems are a significant investment (machines generally start at $1,000+).Speed: Manual processes are slower, averaging 10-20 components per minute. Automated systems are significantly faster, handling hundreds to thousands of components per hour.

● Precision: Manual precision varies with operator skill. Automated systems offer high, consistent results.

● Best For: Manual forming is ideal for prototyping and small batches. Automated forming is best suited for high-volume production.

For hobbyists or small-scale PCB prototype manufacturing, manual tools are often sufficient. However, for operations looking to scale production, investing in automated equipment can yield substantial time savings and ensure unwavering consistency in leaded assembly.

Concluding Thoughts: Achieving Reliability Through Precise Lead Forming

Component lead forming is a foundational skill in leaded assembly, directly influencing the quality and long-term reliability of electronic products. By gaining a deep understanding of axial and radial lead forming techniques, utilizing appropriate lead bending tools, and adhering to best practices for lead cutting, you can consistently achieve professional-grade results. Whether you are manually assembling a single prototype or overseeing an automated production line, precision in component lead forming is absolutely essential.

Dedicate time to refining your techniques, invest in high-quality tools, and diligently follow the guidelines provided in this guide. These steps will not only enhance your assembly processes but also guarantee that your PCBs perform reliably and robustly in real-world applications. By carefully shaping leads, we can build electronics that are truly built to last.