Introduction

High Density Interconnect (HDI) assembly plays a critical role in modern electronics, enabling compact designs with enhanced functionality. Selecting the right materials for HDI assembly is vital to ensure reliability, performance, and manufacturability. This process involves evaluating dielectric materials, copper foil types, and resin systems while considering properties like thermal conductivity and dielectric constant. For electric engineers, understanding these material choices impacts signal integrity, thermal management, and overall board durability. This article explores the key considerations in material selection for HDI assembly, providing practical insights and aligning with recognized industry standards. The goal is to guide professionals in making informed decisions that balance performance with production feasibility.

What Is HDI Assembly and Why Material Selection Matters

HDI assembly refers to the process of constructing printed circuit boards with high-density interconnects, characterized by fine lines, small vias, and multiple layers. These boards are essential in applications like smartphones, medical devices, and automotive systems where space is limited. Material selection directly influences the electrical performance, mechanical stability, and thermal behavior of HDI PCBs. Poor choices can lead to signal loss, overheating, or structural failures. For instance, dielectric materials affect impedance control, while copper foil impacts conductivity. Resin systems determine adhesion and thermal resistance. Electric engineers must prioritize materials that meet stringent requirements to ensure long-term reliability under demanding conditions. Proper selection also aids in meeting industry standards and optimizing manufacturing processes.

Technical Principles Behind Material Selection in HDI Assembly

Dielectric Materials and Dielectric Constant

Dielectric materials form the insulating layers between conductive traces in HDI boards. The dielectric constant, a measure of a material's ability to store electrical energy, is a crucial parameter. A lower dielectric constant reduces signal delay and crosstalk, which is vital for high-speed applications. Materials with a dielectric constant between 3.0 and 4.5 are often preferred for HDI designs to balance performance and cost. These materials must also exhibit low loss tangent to minimize signal attenuation. Engineers evaluate dielectric properties under operating frequencies to ensure compatibility with design specifications.

Copper Foil Types and Conductivity

Copper foil serves as the conductive layer in HDI boards, and its selection impacts electrical performance and manufacturability. Standard electrodeposited copper and rolled annealed copper are common choices. Electrodeposited copper offers better adhesion to dielectric layers, suitable for fine-line etching in HDI designs. Rolled annealed copper provides superior flexibility, beneficial for multilayer structures. Surface roughness of the foil also affects signal integrity at high frequencies. Smoother foils reduce skin effect losses, enhancing performance. Engineers must match copper foil thickness, typically ranging from 12 to 35 micrometers, to current carrying requirements and layer stackup constraints.

Resin Systems for Structural Integrity

Resin systems bind dielectric materials and copper layers, providing mechanical strength and thermal stability. Epoxy-based resins are widely used due to their robust adhesion and cost-effectiveness. For high-performance HDI boards, polyimide or cyanate ester resins offer superior thermal resistance and lower moisture absorption. The glass transition temperature of the resin, which indicates thermal stability, must exceed the operating and assembly temperatures. Compatibility with manufacturing processes, such as lamination and drilling, is another key factor. Selecting the appropriate resin system ensures durability during thermal cycling and prevents delamination.

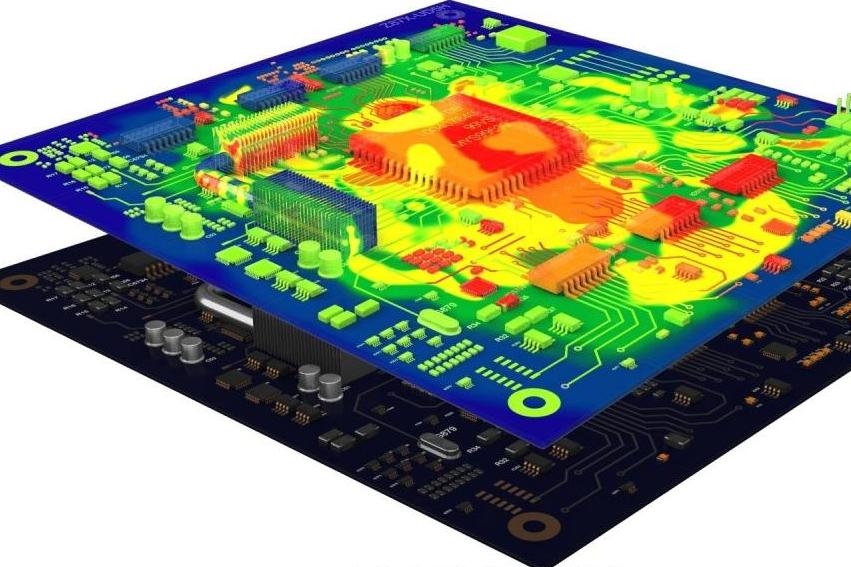

Thermal Conductivity for Heat Management

Thermal conductivity measures a material's ability to transfer heat, a critical consideration in HDI assembly. High-density designs generate significant heat due to compact layouts and high-power components. Materials with higher thermal conductivity dissipate heat effectively, preventing hotspots that degrade performance. Dielectric layers with enhanced thermal conductivity, often achieved through fillers, are preferred for power-intensive applications. Copper layers also contribute to heat dissipation, making foil thickness and layout design relevant. Balancing thermal conductivity with other properties like electrical insulation ensures optimal performance without compromising board integrity.

Interaction of Properties in HDI Design

The interplay between dielectric constant, thermal conductivity, and mechanical properties influences HDI board behavior. A material with a low dielectric constant may have lower thermal conductivity, necessitating design trade-offs. Similarly, resin systems with high thermal stability might increase rigidity, affecting flexibility in multilayer boards. Copper foil selection must align with dielectric and resin properties to avoid mismatches during thermal expansion. Engineers use simulation tools to predict how these interactions affect signal integrity and thermal performance, ensuring materials work cohesively in the final assembly.

Best Practices for Material Selection in HDI Assembly

Aligning Materials with Design Requirements

Start by defining the electrical and thermal requirements of the HDI design. For high-speed circuits, prioritize dielectric materials with low dielectric constant and loss tangent. In power electronics, focus on thermal conductivity to manage heat dissipation. Review operating conditions, such as temperature ranges and humidity, to select resin systems with adequate stability. Use industry standards like IPC-6012E for guidance on material performance specifications. This ensures that chosen materials meet both design and reliability criteria.

Evaluating Material Compatibility

Ensure compatibility between dielectric materials, copper foil, and resin systems during manufacturing processes. For instance, resin flow characteristics must match lamination parameters to avoid voids or incomplete bonding. Copper foil surface treatments should enhance adhesion without compromising etching precision for fine lines. Test material combinations under simulated assembly conditions to identify potential issues like warpage or delamination. Adhering to standards such as IPC-A-600K helps maintain quality during material integration.

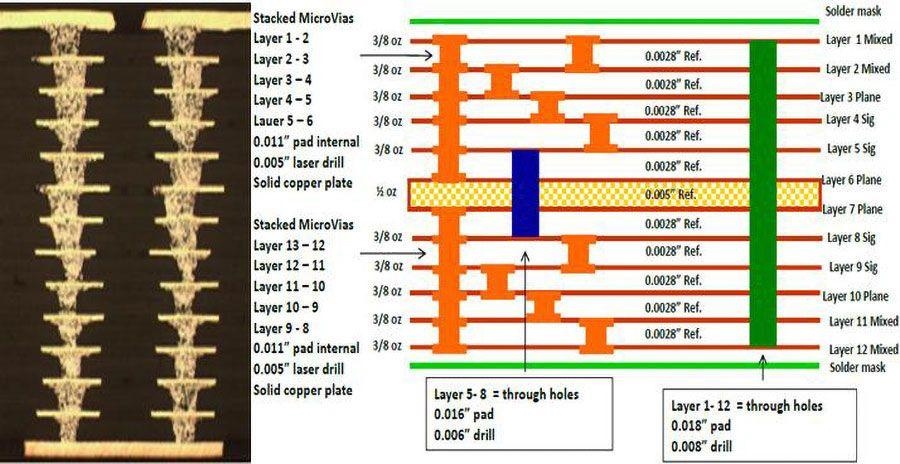

Considering Manufacturing Constraints

Material selection must account for manufacturing capabilities and constraints. Thin dielectric layers enable finer vias but may pose challenges in handling and drilling. High-performance resin systems can increase processing temperatures, requiring adjustments in lamination cycles. Copper foil thickness impacts etching accuracy for microvias, a hallmark of HDI designs. Collaborate with fabrication teams to verify that selected materials align with equipment limitations and process controls. Following guidelines from IPC-2226, which addresses HDI design and manufacturing, supports seamless production.

Balancing Cost and Performance

While advanced materials improve HDI performance, they often raise PCB cost. Engineers must balance performance needs with budget constraints. For example, standard epoxy resins may suffice for less demanding applications, while polyimide resins are reserved for extreme conditions. Similarly, opting for thinner copper foils can reduce material expenses but requires careful handling to prevent defects. Evaluate long-term reliability against initial costs to avoid failures that incur higher expenses. Standards like ISO 9001:2015 provide frameworks for quality management in material selection decisions.

Testing and Validation

Validate material choices through rigorous testing before full-scale production. Conduct thermal cycling tests to assess resin system durability under temperature fluctuations. Measure dielectric constant and loss tangent across frequency ranges to confirm electrical performance. Use thermal conductivity testing to ensure heat dissipation meets design goals. Adhere to testing protocols outlined in standards such as JEDEC J-STD-020E for moisture and reflow sensitivity. Document results to build a reference for future HDI assembly projects, ensuring continuous improvement.

Practical Insight: Troubleshooting Material-Related Issues

In HDI assembly, material mismatches often lead to failures like delamination or signal degradation. A common issue is resin incompatibility with high-frequency dielectric materials, causing poor bonding during lamination. Engineers can address this by selecting resin systems with matching thermal expansion coefficients. Another challenge is copper foil roughness affecting signal integrity in high-speed designs. Opting for low-profile foils mitigates this risk. Thermal conductivity mismatches may result in localized overheating, solvable by integrating thermally conductive fillers in dielectric layers. Regular inspection, aligned with IPC-A-600K acceptability criteria, helps identify material defects early. Drawing from experience, prioritizing small-scale prototyping before mass production uncovers potential material issues, saving time and resources.

Conclusion

Selecting the right materials for HDI assembly is a foundational step in achieving reliable, high-performance printed circuit boards. Dielectric materials, copper foil, and resin systems each play distinct roles, influenced by properties like thermal conductivity and dielectric constant. Electric engineers must align material choices with design requirements, manufacturing capabilities, and industry standards to ensure success. By following best practices and conducting thorough validation, professionals can mitigate risks and enhance board longevity. A methodical approach to material selection empowers teams to tackle the complexities of HDI designs with confidence, delivering solutions that meet the demands of modern electronics.

FAQs

Q1: How does dielectric constant impact HDI assembly performance?

A1: The dielectric constant affects signal speed and crosstalk in HDI assembly. A lower value reduces delays and interference, crucial for high-speed circuits. Materials with a dielectric constant between 3.0 and 4.5 often provide a good balance for performance. Engineers must test this property under operating conditions to ensure signal integrity, especially in compact multilayer designs.

Q2: Why is thermal conductivity important in material selection for HDI boards?

A2: Thermal conductivity determines how well materials dissipate heat in HDI boards. High-density designs generate significant heat, risking component damage if not managed. Selecting dielectric layers and copper foils with adequate thermal conductivity prevents hotspots. This property ensures reliability in power-intensive applications, maintaining performance under thermal stress.

Q3: What role does copper foil play in HDI assembly reliability?

A3: Copper foil forms the conductive pathways in HDI assembly, impacting electrical performance. Its type and thickness influence current capacity and signal integrity. Smoother foils reduce losses at high frequencies, while proper adhesion prevents delamination. Choosing the right copper foil enhances board durability and manufacturing precision.

Q4: How do resin systems affect HDI board durability?

A4: Resin systems provide structural integrity in HDI boards by bonding layers. They must withstand thermal cycling and moisture to prevent cracking or delamination. High-performance resins like polyimide offer superior stability for harsh conditions. Proper selection ensures long-term reliability during assembly and operation.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-2226 — Design Standard for High Density Interconnect (HDI) Printed Boards. IPC, 2003.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.