Introduction

Manual soldering remains a critical skill in electronics assembly, especially when automated processes are impractical or when working on repairs and prototypes. In harsh environments, where temperature extremes, humidity, vibration, and contaminants challenge the integrity of soldered connections, achieving reliable connections becomes even more vital. Harsh conditions can degrade solder joints, leading to failures in critical systems such as aerospace, automotive, and industrial electronics. This article explores the intricacies of soldering in harsh environments, focusing on techniques that ensure durability and performance. From understanding environmental factors to adopting best practices for electronics assembly, we aim to equip electrical engineers with actionable insights for maintaining connection reliability under tough conditions.

Why Manual Soldering in Harsh Environments Matters

Harsh environments expose electronic assemblies to stressors that can compromise solder joint integrity. These settings often involve extreme temperatures, high humidity, corrosive elements, and mechanical shocks. For instance, equipment in marine applications faces saltwater exposure, while aerospace systems endure rapid thermal cycling. Unlike standard production scenarios where engineers weigh wave soldering vs. hand soldering, manual intervention in such contexts is often necessary for field repairs or small batch production where automation is unavailable. Reliable connections are essential to prevent system failures, which could have severe safety or operational consequences. Ensuring robust solder joints under these conditions requires a deep understanding of environmental factors and tailored soldering techniques. The ability to create durable connections directly impacts the longevity and performance of electronic systems in demanding applications.

Environmental Factors Affecting Soldered Connections

Several environmental factors play a significant role in the reliability of soldered connections. Understanding these challenges is the first step in adapting soldering techniques for harsh conditions.

- Temperature Extremes: Rapid changes or sustained high and low temperatures can cause thermal expansion and contraction, stressing solder joints and leading to cracks or fatigue.

- Humidity and Moisture: Water vapor can penetrate assemblies, causing corrosion or short circuits, especially in unprotected solder joints.

- Chemical Exposure: Corrosive substances, such as saltwater or industrial chemicals, can degrade solder materials over time, weakening connections.

- Mechanical Stress: Vibration and shock, common in automotive or aerospace applications, can fracture solder joints if not properly reinforced.

- Dust and Particulates: Accumulation of debris can interfere with electrical conductivity or create unintended pathways for current.

These environmental factors necessitate specialized approaches in electronics assembly to ensure that soldered connections withstand the rigors of harsh settings.

Technical Principles of Soldering in Harsh Environments

The foundation of reliable soldering lies in understanding the interaction between materials, processes, and environmental stressors. Solder joint reliability is governed by metallurgical bonding, thermal dynamics, and mechanical stability. When soldering in harsh environments, these principles become even more critical.

Solder alloys must form a strong intermetallic bond with the base materials, typically copper pads or component leads. However, environmental factors like humidity can oxidize surfaces, hindering proper wetting and adhesion. Thermal cycling can exacerbate micro-cracks due to differing expansion rates between solder and substrate materials. Standards such as IPC J-STD-001H provide guidelines for soldering processes to ensure joint integrity under stress. This standard emphasizes proper flux application, heat control, and post-soldering inspection to mitigate risks. Additionally, mechanical stresses require solder joints to have adequate strength, often achieved through precise control of solder volume and joint geometry during manual soldering.

Practical Soldering Techniques for Reliable Connections

Achieving reliable connections in harsh environments demands meticulous attention to soldering techniques and material selection. Below are actionable best practices tailored for electrical engineers working in challenging conditions.

Surface Preparation and Cleanliness

Before soldering, surfaces must be free of oxides, dirt, and contaminants. Oxidation is accelerated in humid or corrosive environments, so cleaning with appropriate solvents or abrasive tools is crucial. Flux application, as guided by IPC J-STD-001H, helps remove oxides during soldering and promotes better wetting. Choosing a flux type suited for the environment, such as no-clean or water-soluble options, can minimize residue-related issues.

Selecting the Right Solder Alloy

Solder alloy selection impacts long-term reliability. Lead-free solders, often based on tin-silver-copper compositions, are common due to regulatory requirements. However, their higher melting points require precise heat control to avoid component damage. For extreme temperatures, specialized alloys with enhanced thermal fatigue resistance may be considered, adhering to standards like IPC J-STD-006C for solder material specifications.

Controlled Heat Application

Excessive heat can damage components or substrates, while insufficient heat leads to cold solder joints. Using a temperature-controlled soldering iron with a suitable tip ensures consistent heat delivery. Preheating the assembly in high-humidity environments can prevent thermal shock and improve solder flow. Standards such as IPC-A-610J outline acceptable criteria for solder joint appearance and thermal management during manual soldering.

Joint Design and Reinforcement

Solder joint geometry affects mechanical strength. Fillet shapes should be concave and smooth to distribute stress evenly, as per IPC-A-610J guidelines. In vibration-prone environments, adding mechanical support like adhesives or conformal coatings after soldering can protect joints. Ensuring adequate solder volume avoids weak connections without creating bridges or shorts.

Post-Soldering Protection

After soldering, protecting joints from environmental factors is essential. Conformal coatings or encapsulants shield against moisture and chemicals, while proper enclosure design can mitigate dust and mechanical stress. Inspection under IPC-A-600K standards ensures no defects compromise reliability.

For more practical soldering techniques, see our PCB Soldering guide: The Definitive Guide to PCB Soldering: Standards, Techniques, and Strategic Implementation

Troubleshooting Common Issues in Harsh Environment Soldering

Even with careful techniques, issues can arise during manual soldering in harsh conditions. Identifying and addressing these problems ensures reliable connections.

- Cold Solder Joints: These occur due to insufficient heat, often in cold or humid settings. Reheating with proper flux application can resolve this, ensuring a shiny, smooth joint as per IPC-A-610J criteria.

- Cracked Joints: Thermal cycling or vibration may cause cracks. Reinforcing with additional solder or mechanical support, while adhering to IPC J-STD-001H, can prevent recurrence.

- Corrosion: Exposure to moisture or chemicals can corrode joints. Applying protective coatings post-soldering and using corrosion-resistant materials mitigates this risk.

- Insufficient Wetting: Poor surface preparation or oxidized pads lead to weak bonds. Thorough cleaning and appropriate flux use, following IPC guidelines, correct this issue.

Regular inspection and testing under simulated harsh conditions help identify potential failures early.

Adapting Electronics Assembly for Extreme Conditions

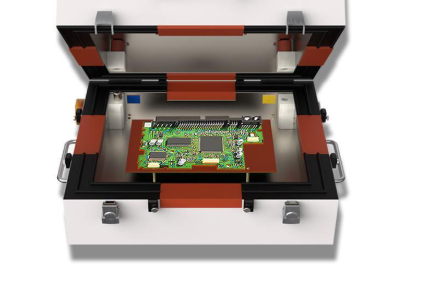

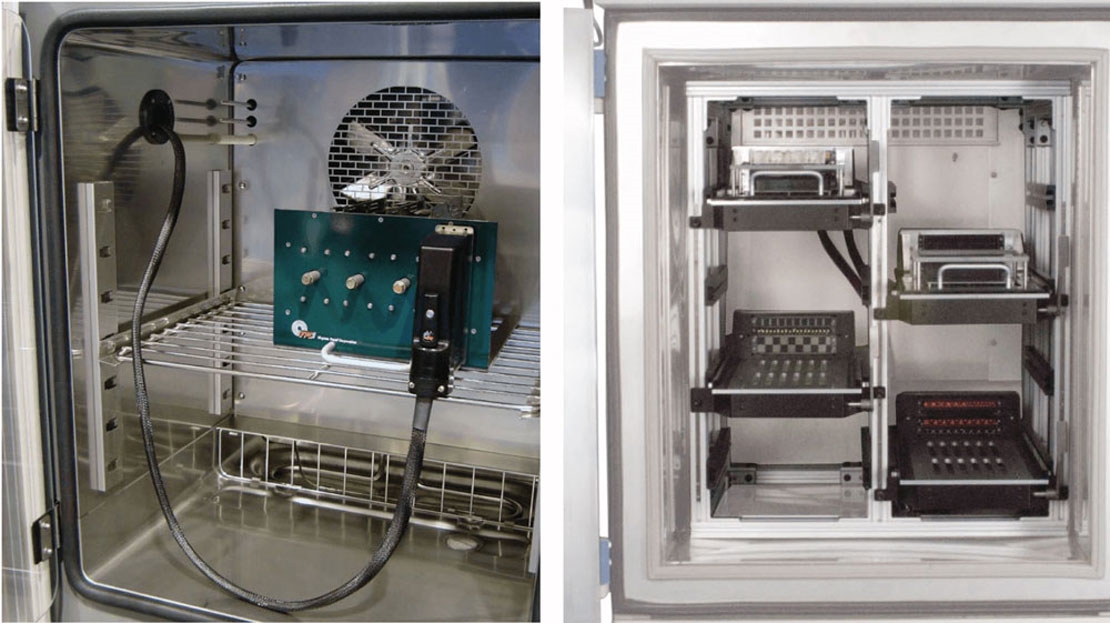

Beyond individual soldering techniques, the broader electronics assembly process must adapt to harsh environments. Component selection should prioritize parts rated for extreme conditions, as specified in standards like JEDEC J-STD-020E for moisture and reflow sensitivity. Assembly layouts should minimize stress points, with traces and pads designed to reduce thermal and mechanical strain. Additionally, testing assemblies under simulated environmental conditions, such as thermal cycling or vibration tests, validates reliability before deployment. Incorporating these considerations into the assembly process complements manual soldering efforts, ensuring overall system durability.

Conclusion

Manual soldering in harsh environments presents unique challenges that demand precision, material awareness, and adherence to industry standards. Environmental factors like temperature extremes, humidity, and mechanical stress can undermine solder joint reliability if not addressed through proper techniques. By focusing on surface preparation, controlled heat application, and post-soldering protection, engineers can achieve reliable connections in even the toughest conditions. Standards such as IPC J-STD-001H and IPC-A-610J provide essential guidance for maintaining quality in electronics assembly. With these practices, electrical engineers can ensure the durability and performance of soldered connections, safeguarding critical systems against environmental challenges.

FAQs

Q1: What are the key environmental factors affecting soldering in harsh environments?

A1: Environmental factors like temperature extremes, humidity, chemical exposure, mechanical stress, and dust impact solder joint reliability. These conditions can cause thermal fatigue, corrosion, or physical damage to connections. Proper soldering techniques, such as surface cleaning and protective coatings, help mitigate these risks and ensure durable electronics assembly in challenging settings.

Q2: How can soldering techniques improve reliable connections in extreme conditions?

A2: Reliable connections in extreme conditions require controlled heat application, proper flux use, and suitable solder alloys. Following standards like IPC J-STD-001H ensures strong metallurgical bonds. Additionally, post-soldering protection with coatings and thorough inspection enhances joint durability against environmental stressors during electronics assembly.

Q3: What standards guide manual soldering for harsh environments?

A3: Standards such as IPC J-STD-001H and IPC-A-610J provide guidelines for manual soldering processes and acceptability criteria. These ensure consistent quality and reliability of solder joints under harsh conditions. They cover material selection, heat control, and inspection methods critical for robust electronics assembly.

Q4: How do I protect solder joints from environmental factors after soldering?

A4: Protect solder joints by applying conformal coatings or encapsulants to shield against moisture and chemicals. Use enclosures to guard against dust and mechanical stress. Regular inspection under standards like IPC-A-600K helps detect issues early, ensuring long-term reliability in harsh environments during electronics assembly.

References

IPC J-STD-001H — Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2021.

IPC-A-610J — Acceptability of Electronic Assemblies. IPC, 2023.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC J-STD-006C — Requirements for Electronic Grade Solder Alloys and Fluxed and Non-Fluxed Solid Solders for Electronic Soldering Applications. IPC, 2013.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.