Introduction

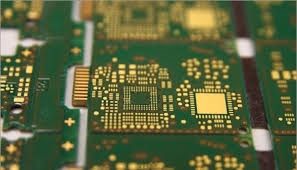

In the intricate world of printed circuit board assembly, the step-down stencil plays a pivotal role in ensuring precise solder paste application for components with varying heights. Selecting the right foil material for these stencils directly impacts the quality of solder joints and overall assembly reliability. Engineers and assembly professionals must consider factors like durability, precision, and compatibility with fine-pitch components when choosing a stencil material. This article explores the characteristics of common materials such as stainless steel, nickel, and fine-grain steel, along with the role of stencil coating in enhancing performance. By understanding the properties of each option, technical teams can make informed decisions to optimize their surface mount technology processes and meet stringent industry standards for quality and efficiency.

What Is a Step-Down Stencil and Why It Matters

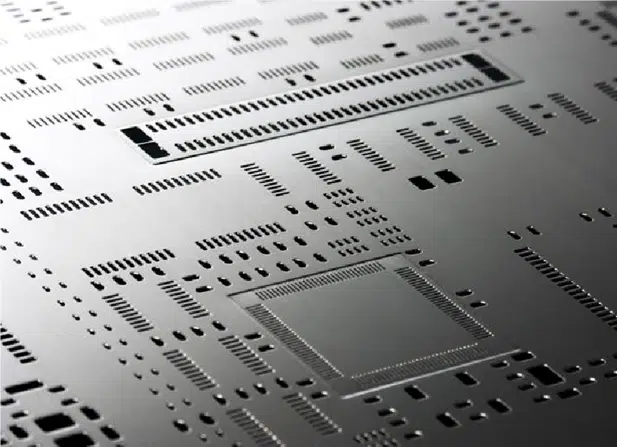

A step-down stencil is a specialized tool used in surface mount technology assembly to apply solder paste at different thicknesses across a single printed circuit board. This is crucial for boards with components of varying heights or package types, where uniform paste deposition would lead to insufficient or excessive solder. The stencil features areas of reduced thickness, or steps, to control paste volume precisely for smaller or fine-pitch components while maintaining adequate volume for larger ones.

The choice of stencil material significantly affects the accuracy of paste deposition, stencil longevity, and overall assembly quality. Poor material selection can result in uneven paste application, stencil wear, or misalignment, leading to defects like bridging or insufficient solder joints. For electrical engineers, understanding the material properties ensures compliance with design specifications and enhances production yield, making this decision a critical step in the assembly process.

Technical Principles of Stencil Materials

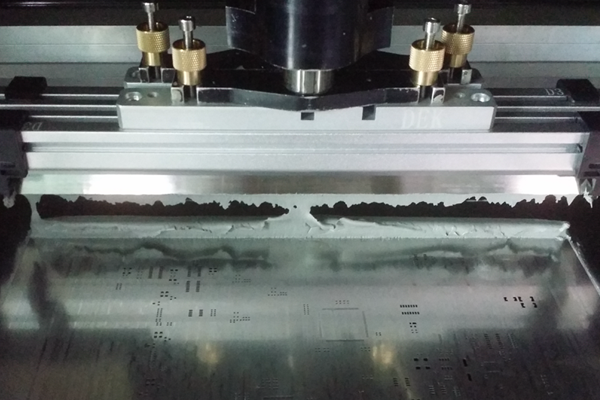

The performance of a step-down stencil relies on the mechanical and chemical properties of the foil material used in its construction. Below, key materials are analyzed based on their suitability for precision assembly tasks.

Stainless Steel Stencil

Stainless steel remains the most widely used material for stencil fabrication due to its balance of strength, durability, and cost-effectiveness. It offers excellent resistance to corrosion, which is vital when exposed to solder pastes with flux components. Stainless steel stencils can withstand repeated use and cleaning cycles without deforming, making them ideal for high-volume production environments. Their rigidity ensures consistent contact with the printed circuit board surface, aiding in accurate paste transfer. However, stainless steel may struggle with extremely fine apertures due to limitations in laser-cutting precision at very small scales.

Nickel Stencil

Nickel stencils are often chosen for applications requiring superior precision, especially with fine-pitch components. Nickel has a smoother surface finish compared to stainless steel, which reduces friction during solder paste release and minimizes paste adhesion to the stencil walls. This property enhances transfer efficiency for small apertures. Additionally, nickel's inherent hardness allows for thinner foils without sacrificing durability, supporting intricate step-down designs. The primary drawback is cost, as nickel stencils are more expensive to produce and may not be justified for less demanding applications.

Fine-Grain Steel Stencil

Fine-grain steel is a specialized variant of stainless steel engineered for improved laser-cutting accuracy. Its microstructure allows for cleaner and more precise aperture edges, which is critical for fine-pitch and ultra-fine-pitch components. This material reduces burr formation during cutting, leading to better paste release and less risk of defects. Fine-grain steel stencils are particularly valued in advanced assembly processes where tight tolerances are non-negotiable. Like standard stainless steel, they offer good durability but may come at a higher cost due to the specialized manufacturing process.

Role of Stencil Coating

Stencil coating is an additional consideration that can enhance the performance of any base material. Coatings, often based on proprietary polymer or nano-coating technologies, are applied to reduce solder paste adhesion and improve release characteristics. This is especially beneficial for fine-pitch applications where paste sticking can cause inconsistent deposits. Coatings also protect the stencil from wear and chemical degradation during cleaning, extending its usable life. However, the effectiveness of a coating depends on its compatibility with the stencil material and the specific solder paste used in the process.

Practical Solutions for Selecting Stencil Materials

Choosing the right foil for a step-down stencil requires balancing technical requirements with practical constraints. Below are key considerations and best practices for electrical engineers and assembly professionals.

Assessing Component Requirements

Start by evaluating the component types on the printed circuit board. Fine-pitch and ultra-fine-pitch components, such as quad flat no-lead packages or chip-scale packages, demand materials with high precision, like nickel or fine-grain steel. For mixed assemblies with larger components, a stainless steel stencil may suffice due to its durability and lower cost. Review design files to identify the smallest aperture size and pitch to ensure the material supports the required accuracy.

Evaluating Production Volume

Production volume influences material selection based on stencil longevity. High-volume runs benefit from durable materials like stainless steel or coated options that resist wear over thousands of cycles. For low-volume or prototype runs, cost considerations might favor stainless steel over more expensive alternatives like nickel, provided the precision requirements are met.

Considering Aperture Design and Step Complexity

Step-down stencils often feature complex designs with multiple thickness levels. Materials like nickel and fine-grain steel offer better compatibility with intricate laser-cut patterns due to their smoother edges and thinner foil options. If the stencil includes extreme step reductions or very small apertures, prioritize materials that minimize burrs and ensure clean paste release.

Testing Stencil Coating Compatibility

If opting for a coated stencil, verify compatibility with the solder paste and cleaning chemicals used in your process. Some coatings may degrade under specific flux compositions or solvents, reducing their effectiveness. Conduct small-scale tests to assess paste release and stencil durability before committing to full production.

Adhering to Industry Standards

Ensure that SMT stencil design and material selection align with recognized industry standards. For instance, IPC-7525B, titled Stencil Design Guidelines, provides recommendations on material thickness, aperture design, and step configurations to achieve optimal solder paste deposition. Following such guidelines helps maintain consistency and reliability in assembly outcomes, reducing the risk of defects.

Troubleshooting Common Stencil Material Issues

In practice, assembly engineers often encounter challenges related to stencil materials that affect solder paste application. Below are common issues and material-specific solutions.

Uneven Paste Deposition

Uneven paste deposition often results from material deformation or poor surface finish. Stainless steel stencils may warp under stress if not properly supported during printing. Using a rigid frame and ensuring even pressure distribution can mitigate this. For nickel stencils, verify that the surface remains free of scratches, as imperfections can disrupt paste release.

Paste Sticking to Stencil Walls

Paste adhesion is a frequent issue with fine-pitch apertures. Nickel stencils and coated options generally perform better in this regard due to their smoother surfaces. If using stainless steel, consider adding a compatible stencil coating to reduce sticking. Regular cleaning with appropriate solvents also prevents buildup that exacerbates adhesion problems.

Wear and Tear in High-Volume Runs

Stencils in high-volume production can suffer from wear, leading to degraded aperture edges. Stainless steel offers good resistance to wear but may still require periodic replacement. Fine-grain steel provides enhanced durability for critical applications, while coatings can further protect against abrasion and chemical exposure during cleaning cycles.

Suggested Reading: Step Down Stencil: The Impact on PCB Rework and Repair

Conclusion

Selecting the best foil for a step-down stencil is a critical decision that influences the quality and reliability of printed circuit board assembly. Stainless steel stencils offer a cost-effective and durable solution for many applications, while nickel stencils provide superior precision for fine-pitch components. Fine-grain steel strikes a balance by enhancing laser-cutting accuracy for intricate designs. Additionally, stencil coating can improve paste release and extend stencil life across all materials. By carefully assessing component requirements, production volume, and design complexity, electrical engineers can choose the most suitable material to ensure consistent solder paste application and minimize assembly defects. Adhering to established industry standards further supports achieving optimal results in surface mount technology processes.

FAQs

Q1: What are the advantages of using a stainless steel stencil for step-down designs?

A1: A stainless steel stencil offers durability and corrosion resistance, making it ideal for high-volume production. It withstands repeated use and cleaning without deforming, ensuring consistent solder paste application. Its cost-effectiveness compared to other materials makes it a practical choice for many assemblies, though it may lack the precision of alternatives for ultra-fine-pitch components.

Q2: How does a nickel stencil improve performance in fine-pitch applications?

A2: A nickel stencil provides a smoother surface finish, reducing solder paste adhesion and improving release for fine-pitch apertures. Its hardness allows for thinner foils, supporting intricate step-down designs. This material ensures higher precision in paste deposition, which is critical for small components, though it comes at a higher cost than stainless steel options.

Q3: Why consider a fine-grain steel stencil for complex PCB layouts?

A3: A fine-grain steel stencil is engineered for superior laser-cutting accuracy, resulting in cleaner aperture edges. This minimizes burrs and enhances paste release, making it suitable for complex layouts with fine-pitch components. It offers durability similar to stainless steel but with improved precision, ideal for advanced assembly requirements.

Q4: What role does stencil coating play in solder paste application?

A4: Stencil coating reduces solder paste adhesion to aperture walls, improving transfer efficiency, especially in fine-pitch designs. It also protects the stencil from wear and chemical damage during cleaning, extending its lifespan. Compatibility with paste and solvents must be tested to ensure the coating maintains performance over time.

References

IPC-7525B - Stencil Design Guidelines. IPC, 2011.

IPC-A-600K - Acceptability of Printed Boards. IPC, 2020.