Introduction

Estimating the budget for a printed circuit board project is a critical step for electrical engineers and procurement teams. The complexity of PCB design, manufacturing, and assembly often leads to unexpected costs if not planned carefully. PCB cost calculators and online PCB pricing tools have emerged as essential resources to streamline this process. These tools assist in BOM cost estimation and provide accurate PCB manufacturing quote tools, saving time and reducing errors. This guide explores the functionality of these calculators, their importance in project planning, and best practices for leveraging them effectively. Whether you are designing a prototype or scaling for production, understanding how to estimate costs with precision is vital for success in electronics development.

What Are PCB Cost Calculators and Why Do They Matter

PCB cost calculators are specialized tools designed to estimate the expenses associated with designing, fabricating, and assembling printed circuit boards. These tools typically account for various factors such as board dimensions, layer count, material selection, and component costs. For electrical engineers, using a PCB cost calculator ensures transparency in budgeting and helps align project goals with financial constraints. The significance of these tools lies in their ability to break down complex cost structures into manageable data points. By integrating BOM cost estimation, they allow users to predict expenses for individual components alongside fabrication and assembly costs. This comprehensive approach prevents budget overruns and supports informed decision making during the design phase. In an industry where precision matters, leveraging online PCB pricing tools can be a game changer for project efficiency.

Technical Principles Behind PCB Cost Estimation

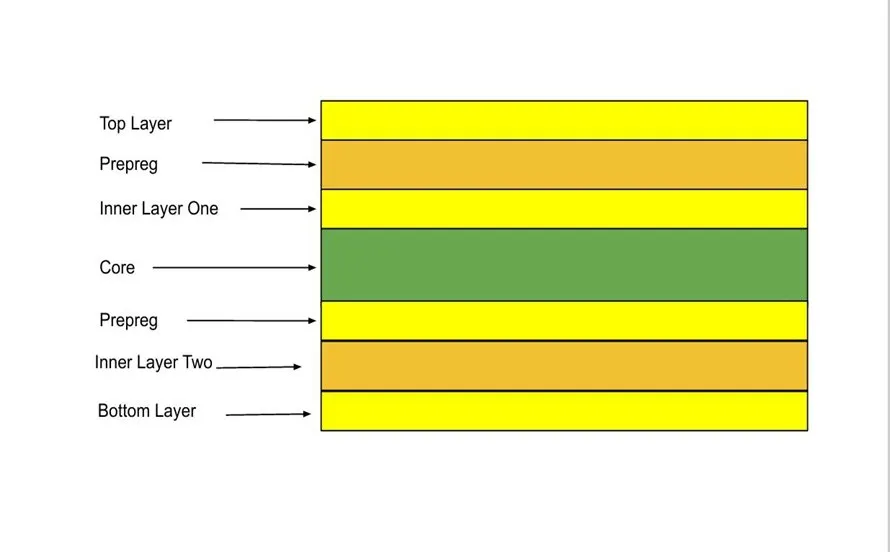

Understanding the technical principles that drive PCB cost estimation is essential for accurate budgeting. Costs are influenced by multiple variables, each tied to specific engineering choices. Board size and layer count directly impact material usage and fabrication complexity. For instance, multilayer boards require more processing steps and higher material costs compared to single layer designs. Material selection, guided by standards such as IPC-6012E, also plays a role, as high frequency laminates or specialized substrates increase expenses. Component costs, a key part of BOM cost estimation, vary based on availability, quantity, and specifications outlined in standards like JEDEC J-STD-020E for moisture sensitivity. Assembly processes, including surface mount technology, add labor and equipment costs, often influenced by placement precision requirements. PCB manufacturing quote tools aggregate these factors, using algorithms to provide estimates that reflect real world production challenges.

Related Reading: PCB Material Costs: Choosing the Right Substrate to Balance Performance and Price

Key Cost Drivers in PCB Projects

Several technical elements contribute to the overall cost of a PCB project. Below is a breakdown of primary factors considered by most PCB cost calculators:

- Board Dimensions and Layers: Larger boards or those with multiple layers require more materials and processing time.

- Material Specifications: Compliance with standards like IPC-A-600K ensures quality but can raise costs with premium materials.

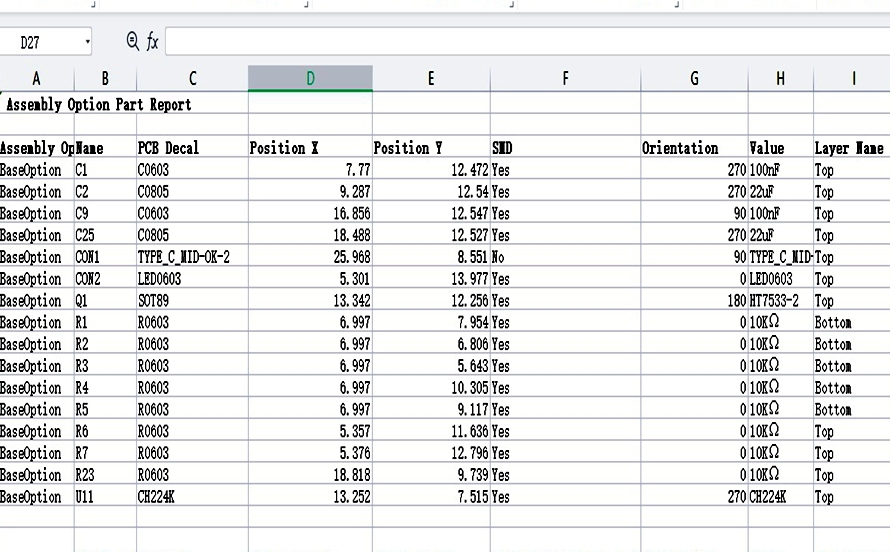

- Component Selection: Costs fluctuate based on component type, sourcing, and quantity as per BOM cost estimation.

- Manufacturing Complexity: Features like fine pitch components or vias add to fabrication difficulty.

- Assembly Requirements: Manual versus automated assembly impacts labor costs significantly.

Understanding these drivers allows engineers to make design choices that balance functionality with budget constraints. Online PCB pricing tools often provide instant feedback on how adjustments to these parameters affect the total cost.

Related Reading: Ways to Reduce PCB Manufacturing Costs

How PCB Cost Calculators Work

PCB cost calculators operate by collecting user inputs on design and manufacturing specifications. These inputs typically include board size, number of layers, material type, and quantity needed. Advanced tools also incorporate BOM cost estimation by allowing users to upload a bill of materials for component pricing analysis. The calculator processes this data against a database of manufacturing costs, labor rates, and material prices. Some PCB manufacturing quote tools factor in additional variables like lead time, which can influence pricing due to expedited processing fees. The output is a detailed cost breakdown, often presented as a quote or estimate, helping engineers visualize expenses across different project phases. This systematic approach aligns with quality management principles outlined in ISO 9001:2015, ensuring consistency and reliability in cost projections

Practical Tips for Using Online PCB Pricing Tools

Leveraging online PCB pricing tools effectively requires a strategic approach. Electrical engineers can follow these practical tips to ensure accurate estimates and optimize project budgets.

Prepare Accurate Design Data

Before using a PCB cost calculator, ensure all design specifications are finalized. This includes board dimensions, layer count, and material requirements as per standards like IPC-6012E. Incomplete or inaccurate data can lead to misleading cost estimates, impacting project planning. Double check the bill of materials for precise BOM cost estimation, ensuring component specifications match design needs.

Compare Multiple Parameters

Experiment with different design configurations within the tool. Adjust variables like layer count or board size to see how they influence costs. Many PCB manufacturing quote tools provide real time updates, allowing users to identify cost effective options without compromising quality. This iterative process helps balance performance with affordability.

Account for Hidden Costs

While online PCB pricing tools provide detailed breakdowns, some costs might not be immediately apparent. Consider expenses related to testing, compliance with standards such as IPC-A-600K, and potential rework. Factor in shipping or customs fees if applicable, as these can add to the overall budget.

Use BOM Integration Features

For projects with extensive component lists, utilize tools that support BOM cost estimation. Uploading a detailed bill of materials ensures accurate pricing for each part, reducing the risk of underestimation. Verify component data against standards like JEDEC J-STD-020E to account for handling or storage requirements that might affect costs.

Plan for Scalability

When estimating costs for prototypes, consider future production volumes. Some PCB cost calculators offer pricing tiers based on quantity, which can reveal savings for bulk orders. Planning ahead helps align initial designs with cost efficient manufacturing strategies for larger runs.

Benefits of Using PCB Manufacturing Quote Tools

PCB manufacturing quote tools offer significant advantages for electrical engineers managing complex projects. These tools provide instant cost insights, eliminating the need for manual calculations or lengthy quote requests. They enhance transparency by breaking down expenses into categories like fabrication, assembly, and components. This detailed view aids in identifying areas for cost reduction without sacrificing quality, aligning with best practices in ISO 9001:2015. Additionally, many tools support real time updates, reflecting current material prices or availability, which is crucial for accurate budgeting. By integrating BOM cost estimation, they ensure a holistic approach to expense tracking. Ultimately, these tools empower engineers to make data driven decisions, streamline workflows, and maintain project timelines within financial limits.

Challenges and Limitations of PCB Cost Calculators

While PCB cost calculators are invaluable, they come with certain challenges. Accuracy depends heavily on the quality of input data; errors in design specifications can skew results. Some online PCB pricing tools may not account for niche requirements, such as specialized materials or unique assembly processes, leading to incomplete estimates. Fluctuations in component pricing, a key aspect of BOM cost estimation, can also affect reliability if the tool’s database is outdated. Additionally, hidden costs like compliance testing per IPC-A-600K or rework might not be included in initial quotes. Engineers must approach these tools as a starting point, supplementing estimates with manual reviews or consultations to address project specific nuances.

Conclusion

PCB cost calculators and online PCB pricing tools are indispensable for electrical engineers seeking to estimate project budgets with precision. By understanding the technical principles behind cost estimation and applying practical strategies, professionals can optimize designs for affordability without compromising quality. These tools, supported by standards like IPC-6012E and ISO 9001:2015, offer transparency and efficiency in managing fabrication, assembly, and component expenses. While challenges exist, such as data accuracy and hidden costs, a methodical approach to using PCB manufacturing quote tools ensures reliable results. Embracing these resources empowers teams to navigate the financial complexities of electronics development, paving the way for successful project outcomes.

FAQs

Q1: How does a PCB cost calculator improve project planning for engineers?

A1: A PCB cost calculator enhances project planning by providing quick, detailed estimates of fabrication and assembly expenses. It helps engineers align designs with budget constraints, avoiding unexpected overruns. By integrating factors like layer count and material selection, it offers actionable insights for cost optimization. This tool streamlines decision making, ensuring projects stay on track financially and technically.

Q2: What factors should be considered in online PCB pricing for accurate estimates?

A2: When using online PCB pricing tools, consider board dimensions, layer count, and material specifications as primary cost drivers. Component selection for BOM cost estimation, manufacturing complexity, and assembly requirements also influence pricing. Ensure compliance with relevant standards and account for potential hidden costs like testing or shipping to achieve accurate budget forecasts.

Q3: How can BOM cost estimation tools assist in managing component expenses?

A3: BOM cost estimation tools assist by analyzing a detailed bill of materials to predict component expenses accurately. They account for quantity, type, and sourcing challenges, helping engineers avoid underestimation. This ensures budgets reflect real world costs, supporting better financial planning and reducing the risk of delays due to unexpected price increases.

Q4: Are PCB manufacturing quote tools reliable for prototype budgeting?

A4: PCB manufacturing quote tools are generally reliable for prototype budgeting, offering quick cost breakdowns for initial designs. However, accuracy depends on input data quality and tool capabilities. They may not capture niche or hidden costs fully. Engineers should use them as a starting point, verifying estimates with additional reviews for comprehensive budgeting.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification. JEDEC, 2014.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.