Introduction

In the world of printed circuit board design and manufacturing, selecting the right substrate material is a critical decision for electrical engineers. The choice directly impacts not only the performance of the final product but also the overall project budget. With a variety of options available, from standard FR4 to high performance PCB materials, understanding the nuances of PCB material cost comparison becomes essential. Engineers must balance performance requirements like signal integrity and thermal stability against cost constraints to achieve optimal results. This article explores cost effective PCB substrates, FR4 alternatives cost considerations, and strategies for balancing performance price PCB needs. The goal is to provide actionable insights for making informed material choices in complex designs.

Why PCB Substrate Selection Matters

The substrate forms the foundation of a printed circuit board, providing mechanical support and electrical insulation between conductive layers. Its properties influence key performance aspects such as dielectric constant, thermal conductivity, and signal loss. For electrical engineers, choosing the right material ensures reliability under specific operating conditions, whether for consumer electronics or high frequency applications. A poor choice can lead to signal degradation, thermal failures, or increased manufacturing expenses. Beyond performance, substrate selection affects cost at every stage, from raw material procurement to fabrication complexity. As project budgets tighten, finding cost effective PCB substrates without compromising quality becomes a priority. This balance is central to successful design and production in competitive industries.

Technical Factors Influencing PCB Material Costs

Several technical properties of substrates determine both their performance and price. Understanding these factors helps engineers align material choices with application needs and budget limits.

Dielectric Constant and Signal Integrity

The dielectric constant of a substrate affects how electrical signals propagate through the board. Materials with lower dielectric constants are preferred for high frequency designs as they minimize signal loss. Standard FR4, widely used due to its affordability, has a dielectric constant around 4.2 to 4.5, suitable for many general applications. However, for high speed circuits, alternatives with lower dielectric constants are often necessary, though they come at a higher cost. This is a key consideration in PCB material cost comparison when performance demands exceed standard capabilities.

Thermal Conductivity and Heat Dissipation

Thermal management is crucial for boards operating in high power or high temperature environments. Substrates with better thermal conductivity dissipate heat more effectively, protecting components from damage. FR4 offers moderate thermal performance, but high performance PCB materials with enhanced conductivity are often required for demanding applications. These materials increase costs significantly, making it essential to evaluate whether the thermal benefits justify the added expense in a given design.

Related Reading: PCB Material Selection: Balancing Thermal Performance and Cost

Mechanical Strength and Durability

Substrate durability affects the board's ability to withstand physical stress during manufacturing and operation. Materials with higher mechanical strength resist warping and cracking, ensuring long term reliability. While standard options like FR4 meet basic requirements at a low cost, more robust FR4 alternatives cost more due to specialized compositions. Engineers must assess environmental conditions and handling risks to decide if premium materials are necessary for durability.

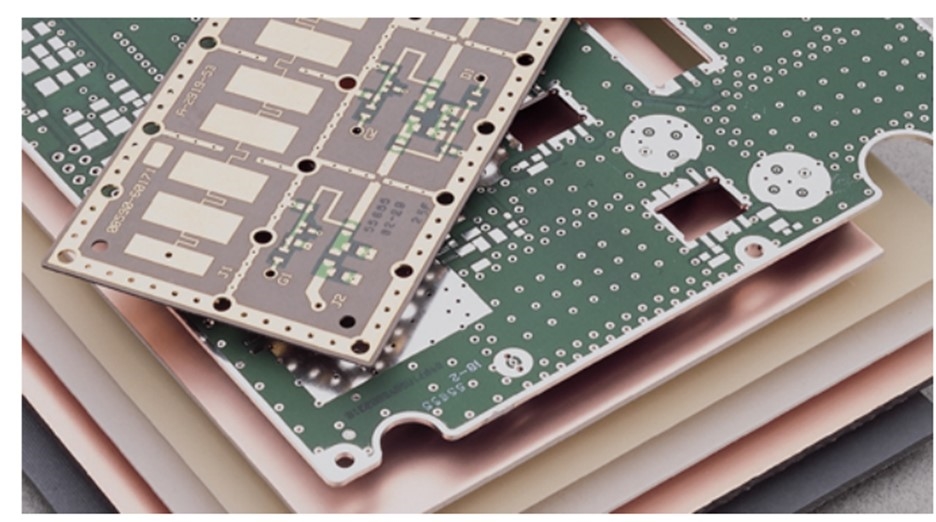

Common PCB Substrates and Cost Comparison

A variety of substrate materials are available, each with distinct performance characteristics and price points. Below is an overview of popular options to aid in balancing performance price PCB decisions.

FR4: The Standard Choice

FR4, a glass reinforced epoxy laminate, remains the most widely used substrate due to its low cost and versatility. It suits a broad range of applications, from consumer electronics to industrial controls, offering acceptable electrical and thermal properties for general use. Its affordability makes it the baseline for PCB material cost comparison. However, limitations in high frequency performance and thermal conductivity often necessitate exploring alternatives for specialized designs.

Polyimide: Flexible and Heat Resistant

Polyimide substrates are known for their flexibility and excellent thermal stability, making them ideal for flexible circuits and high temperature environments. They withstand continuous exposure to elevated temperatures without degrading, a significant advantage over FR4. However, the cost of polyimide is notably higher, often several times that of standard materials. This makes it a less cost effective PCB substrate unless specific performance needs justify the expense.

High Frequency Laminates: Performance at a Premium

For applications requiring minimal signal loss, such as radio frequency and microwave circuits, high frequency laminates are essential. These materials feature low dielectric constants and low loss tangents, ensuring signal integrity at high speeds. While they offer superior performance, their cost can be significantly higher than FR4, often by a factor of five or more. Engineers must carefully weigh these costs against project requirements when considering high performance PCB materials.

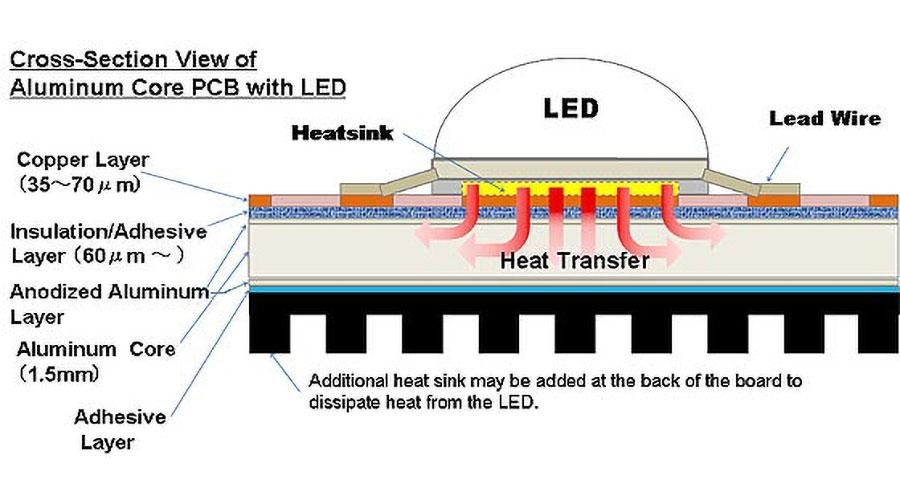

Metal Core Substrates: Enhanced Thermal Management

Metal core substrates, typically with an aluminum or copper base, excel in thermal dissipation for high power applications like LED lighting. They provide a direct path for heat transfer away from components, enhancing reliability. However, their cost is higher due to the complexity of fabrication and material expenses. These are often considered when thermal performance is a critical design factor, despite the impact on budget.

Cost Effective Alternatives to FR4

While FR4 dominates due to its low price, several FR4 alternatives cost considerations can provide better performance without breaking budgets. Below are options for engineers seeking cost effective PCB substrates.

CEM 1 and CEM 3: Budget Friendly Upgrades

CEM 1 and CEM 3 are composite epoxy materials that offer slightly better thermal and mechanical properties than FR4 at a moderate cost increase. They serve as intermediate options for applications needing marginal improvements over standard substrates. While not suited for high frequency or extreme conditions, they provide a practical step up for cost sensitive projects requiring minor performance enhancements.

Related Reading: CEM 1 in Consumer Electronics: Why It Remains a Popular Choice

PTFE Based Materials: High Frequency on a Budget

Polytetrafluoroethylene based substrates offer excellent electrical properties for high frequency applications at a lower cost than some premium laminates. While still more expensive than FR4, certain formulations provide a balance between performance and price. These are viable for designs where signal integrity is critical but budget constraints limit the use of top tier high performance PCB materials.

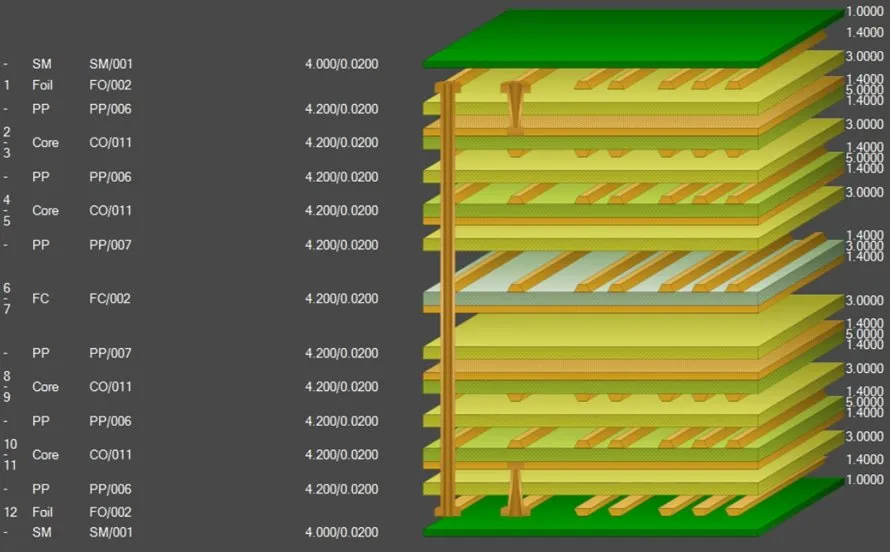

Hybrid Constructions: Combining Materials

Hybrid PCB designs combine different substrates within a single board to optimize performance and cost. For instance, using FR4 for non critical layers and a high frequency material for signal sensitive areas reduces overall expenses. This approach requires careful design to ensure compatibility but can be a strategic way of balancing performance price PCB needs in complex projects.

Best Practices for Balancing Performance and Price

Achieving the right balance between performance and cost requires a structured approach to material selection. Below are practical strategies for electrical engineers.

Define Application Requirements Clearly

Start by identifying the specific electrical, thermal, and mechanical needs of the application. This includes operating frequency, temperature range, and environmental conditions. Clear requirements prevent over specification, which can drive up costs unnecessarily. Use industry standards like IPC 6012E for guidance on performance specifications to ensure alignment with accepted benchmarks.

Evaluate Total Cost of Ownership

Beyond raw material costs, consider fabrication complexity, yield rates, and long term reliability. A cheaper substrate might increase manufacturing defects or fail prematurely, leading to higher overall expenses. Assess the entire lifecycle cost when conducting a PCB material cost comparison to avoid hidden financial burdens.

Leverage Simulation Tools

Use simulation software to predict how different substrates will perform under design conditions. This helps identify the minimum material specifications needed for reliable operation, avoiding over engineering. Simulations can also reveal potential issues like signal loss or thermal hotspots before committing to a material choice.

Consult Industry Standards

Adhere to recognized standards such as IPC A 600K for acceptability criteria when selecting materials. These guidelines provide detailed benchmarks for substrate properties, ensuring choices meet quality and performance expectations. Standards also help in comparing FR4 alternatives cost and performance metrics systematically.

Conclusion

Selecting the right PCB substrate is a pivotal decision for electrical engineers, requiring a careful balance of performance and cost. From the ubiquitous FR4 to specialized high performance PCB materials, each option presents unique benefits and price points. By understanding technical properties like dielectric constant and thermal conductivity, engineers can make informed choices tailored to specific applications. Strategies such as hybrid designs and adherence to industry standards further aid in balancing performance price PCB goals. With a structured approach to PCB material cost comparison, it becomes possible to achieve reliable, high quality designs within budget constraints.

FAQs

Q1: What factors should I consider in a PCB material cost comparison?

A1: When comparing PCB material costs, evaluate dielectric properties, thermal conductivity, and mechanical strength against application needs. Consider fabrication complexity and long term reliability as well. Using industry standards like IPC 6012E helps ensure consistent performance metrics. This approach aids in identifying cost effective PCB substrates without sacrificing essential quality for your design requirements.

Q2: Are there affordable FR4 alternatives cost wise for better performance?

A2: Yes, materials like CEM 1 and CEM 3 offer slight improvements over FR4 at a moderate cost increase. They suit applications needing better thermal or mechanical properties without high frequency demands. For specific needs, PTFE based options provide a balance for high frequency designs. Always align choices with project specifications to avoid unnecessary expenses.

Q3: How do high performance PCB materials impact project budgets?

A3: High performance PCB materials significantly increase costs, often by several times compared to standard FR4. They are essential for applications requiring low signal loss or superior thermal management. However, their price can strain budgets if not justified by design needs. Careful evaluation of requirements ensures these materials are used only when necessary for optimal performance.

Q4: What are cost effective PCB substrates for thermal management?

A4: Metal core substrates, often with aluminum or copper bases, are effective for thermal dissipation in high power applications. While more expensive than FR4, they prevent component damage by efficiently transferring heat. For moderate needs, CEM 3 offers a budget friendly upgrade. Select based on thermal load and cost constraints for best results.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.