Introduction

In the fast-paced world of electronics development, getting products to market quickly is a critical advantage for engineers and designers. Rapid PCB prototyping assembly plays a pivotal role in achieving this goal by significantly reducing development cycles. This process involves quick turn PCB assembly and expedited prototyping to validate designs, test functionality, and iterate efficiently. By leveraging fast PCB fabrication and same day PCB assembly options, teams can address issues early and meet tight deadlines. For electrical engineers, understanding how rapid prototyping services streamline workflows is essential to maintaining a competitive edge. This article explores the principles, benefits, and best practices of rapid PCB prototyping assembly, offering practical insights to accelerate your time to market without compromising on quality or precision.

What Is Rapid Prototype Circuit Board Assembly and Why It Matters

Rapid PCB prototyping assembly refers to the accelerated process of designing, fabricating, and assembling printed circuit boards in a condensed timeframe. Unlike traditional production, which may take weeks, this approach focuses on quick turn PCB assembly, often delivering functional boards within days or even hours through same day PCB assembly services. It typically involves small batch runs to test concepts, verify layouts, and ensure component compatibility before full-scale manufacturing.

The importance of rapid prototyping services lies in their ability to shorten the development cycle. For electrical engineers, this means faster validation of designs and early detection of potential flaws. Reducing time to market is not just about speed; it also minimizes costs associated with prolonged iterations. In industries like consumer electronics, medical devices, and automotive systems, where innovation drives competition, expedited prototyping can determine project success. By enabling swift feedback loops, this process ensures that designs are refined efficiently, maintaining high standards of functionality and reliability.

Technical Principles of Rapid Prototype Circuit Board Assembly

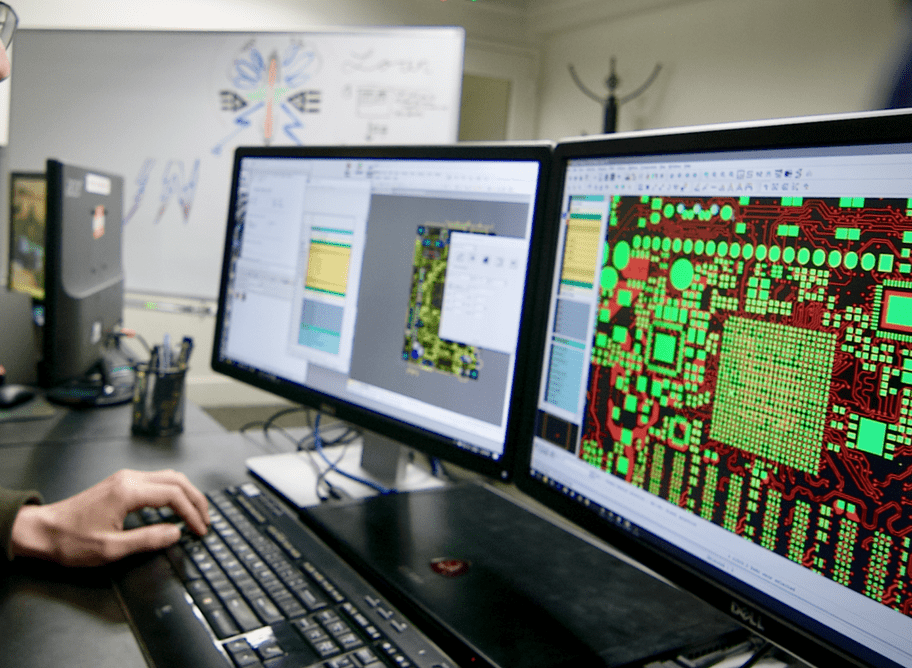

The foundation of rapid PCB prototyping assembly rests on streamlined workflows and advanced manufacturing techniques tailored for speed and precision. The process begins with schematic capture and layout design, followed by fast PCB fabrication. Engineers prioritize design for manufacturability to avoid delays caused by complex layouts or non-standard components. Fabrication often adheres to standards like IPC-6012E, which outlines performance specifications for rigid printed boards, ensuring quality even in expedited timelines.

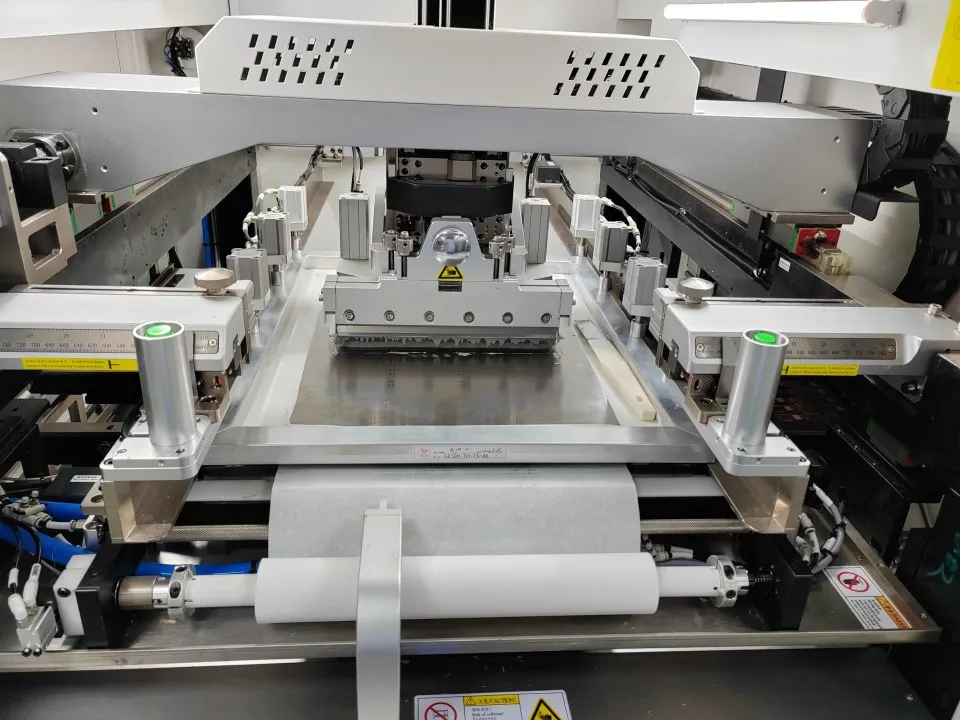

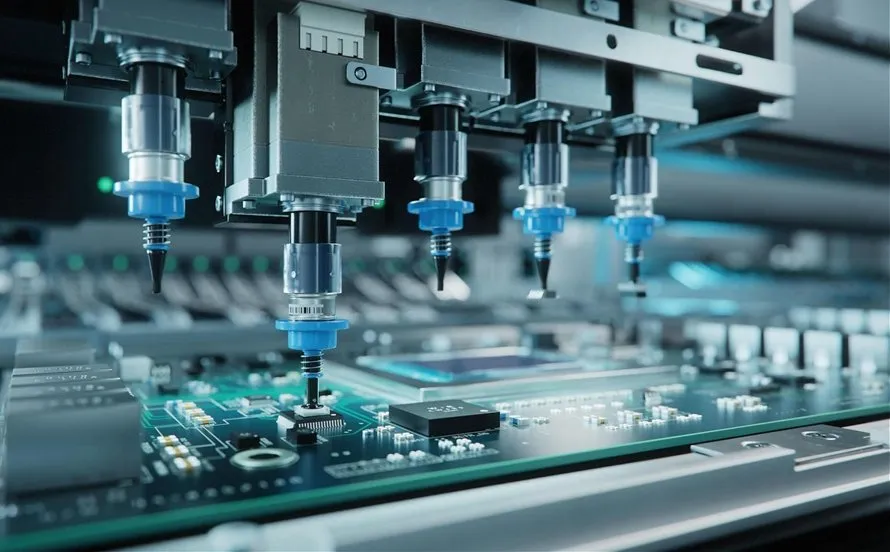

Assembly follows fabrication, where surface mount technology and through-hole components are placed and soldered onto the board. Automated pick-and-place machines and reflow soldering are commonly used to maintain accuracy under tight schedules. Standards such as IPC-A-600K guide the acceptability criteria for assembled boards, ensuring that even rapid processes meet industry benchmarks. Testing, including functional and in-circuit tests, verifies performance before delivery. The integration of these steps into a cohesive, accelerated workflow is what makes quick turn PCB assembly effective for urgent projects.

Related Reading: Beginner's Guide to Using Pick and Place Machines for PCB Assembly

Communication between design teams and manufacturing facilities is another critical principle. Real-time feedback on design files helps resolve issues like incorrect footprints or missing specifications before production starts. This collaboration reduces errors and supports the goal of same day PCB assembly when required.

Benefits of Rapid PCB Prototyping for Time to Market

The primary advantage of rapid PCB prototyping assembly is its direct impact on reducing time to market. By condensing the prototyping phase from weeks to days, engineers can test and iterate designs much faster. This speed is especially valuable in industries where product lifecycles are short, and being first to market offers a significant edge. Expedited prototyping allows for multiple design revisions within a compressed schedule, ensuring that final products are optimized before mass production.

Cost efficiency is another key benefit. Identifying design flaws during the prototyping stage prevents expensive rework in later phases. Rapid prototyping services also enable small batch testing, reducing material waste and inventory costs. For electrical engineers, this means balancing speed with budget constraints effectively. Additionally, the ability to conduct parallel testing of different design variations accelerates decision-making, further shortening development timelines.

Quality assurance remains intact despite the accelerated pace. Adherence to standards like IPC-A-600K ensures that even quickly assembled boards meet visual and functional requirements. This reliability builds confidence in the prototyping process, allowing teams to focus on innovation rather than troubleshooting manufacturing defects.

Best Practices for Implementing Rapid Prototype Circuit Board Assembly

To maximize the benefits of quick turn PCB assembly, electrical engineers must adopt specific best practices during the design and production phases. First, prioritize simplicity in design. Avoid overly complex layer stack-ups or non-standard materials unless absolutely necessary. Following design for manufacturability guidelines reduces the risk of delays during fast PCB fabrication.

Early collaboration with manufacturing partners is essential. Sharing design files in advance allows for quick feedback on potential issues, such as component availability or layout constraints. This step is particularly crucial for same day PCB assembly, where there is little room for error. Ensure that all design documentation, including bill of materials and assembly drawings, is complete and accurate to prevent miscommunication.

Selecting the right prototyping partner also matters. Look for facilities with a proven track record in expedited prototyping and familiarity with industry standards like IPC-6012E. Clear communication about deadlines and testing requirements helps align expectations. Additionally, plan for iterative testing. Allocate time for multiple prototype rounds to refine designs based on test outcomes, ensuring that the final product is robust and market-ready.

Finally, leverage automated tools for design verification. Software that checks for rule violations or signal integrity issues can catch problems before files are sent for production. This proactive approach supports rapid prototyping services by minimizing back-and-forth revisions.

Related Reading: Design for Assembly (DFA) Considerations for High Density PCBs

Common Challenges in Rapid PCB Prototyping and Solutions

While rapid PCB prototyping assembly offers significant advantages, it comes with challenges that engineers must navigate. One common issue is component sourcing delays. In expedited prototyping, last-minute unavailability of specific parts can halt progress. To mitigate this, maintain a list of alternative components with similar specifications and confirm availability early in the process.

Another challenge is maintaining quality under tight deadlines. Rushed fabrication or assembly may lead to overlooked defects if proper checks are not in place. Adhering to standards like IPC-A-600K for visual inspection and functional testing helps ensure that quality is not sacrificed for speed. Allocating time for thorough testing, even in a compressed schedule, is non-negotiable.

Design errors can also derail rapid timelines. Incorrect footprints or mismatched schematics often surface during assembly, causing delays. Implementing design rule checks before submission and involving manufacturing feedback early can prevent such issues. For same day PCB assembly, double-checking critical design elements is a must to avoid costly setbacks.

Insight: Balancing Speed and Reliability in Prototyping

As an assembly engineer, I’ve seen firsthand how the push for speed in rapid PCB prototyping can sometimes clash with the need for reliability. A memorable project involved a tight deadline for a medical device prototype. The team opted for quick turn PCB assembly to meet a critical testing window. While the initial boards were delivered on time, insufficient testing led to a minor signal integrity issue that required a second iteration.

The lesson was clear: speed must be balanced with structured validation. Even in expedited prototyping, following standards like IPC-6012E for fabrication quality and allocating time for basic functional tests can save significant rework later. For engineers under pressure to reduce time to market, my advice is to build a checklist of non-negotiable quality checks. This ensures that fast PCB fabrication does not compromise the integrity of the final design.

Conclusion

Rapid PCB prototyping assembly stands as a cornerstone for electrical engineers aiming to accelerate their time to market. By integrating quick turn PCB assembly, fast PCB fabrication, and same day PCB assembly options, development cycles are drastically shortened without sacrificing quality. The process empowers teams to iterate designs efficiently, address flaws early, and meet stringent deadlines. Adopting best practices like design simplicity, early collaboration, and adherence to standards such as IPC-6012E ensures success in expedited prototyping. As rapid prototyping services continue to evolve, they offer a reliable path to innovation, enabling engineers to bring cutting-edge products to market faster and with greater confidence.

FAQs

Q1: How does quick turn PCB assembly reduce time to market for engineers?

A1: Quick turn PCB assembly compresses the prototyping phase by delivering assembled boards in days rather than weeks. This allows electrical engineers to test and validate designs rapidly, iterate on feedback, and resolve issues early. By shortening development cycles, it ensures faster progression to mass production, giving a competitive edge in industries with tight schedules.

Q2: What are the key considerations for same day PCB assembly success?

A2: For same day PCB assembly, accuracy in design files and component availability are critical. Engineers must ensure complete documentation and verify parts beforehand. Collaboration with manufacturing teams to address potential issues early also helps. Following standards like IPC-A-600K for quality checks ensures that even rushed assemblies meet reliability requirements.

Q3: How do rapid prototyping services benefit small-scale projects?

A3: Rapid prototyping services enable small-scale projects to access fast, cost-effective testing without large batch commitments. Engineers can refine designs through multiple iterations affordably, ensuring functionality before scaling up. This approach minimizes financial risk and supports innovation by providing quick feedback on design performance within tight budgets.

Q4: What role does fast PCB fabrication play in expedited prototyping?

A4: Fast PCB fabrication is the foundation of expedited prototyping, producing boards in minimal time to meet urgent deadlines. It allows engineers to quickly move from design to testing, identifying layout or component issues early. Adhering to standards like IPC-6012E during fabrication ensures quality, supporting seamless assembly and validation processes.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.